Thailand’s PTT Exploration and Production Public Company (PTTEP) has shared new details about its plan to convert flare gas into carbon nanotubes.

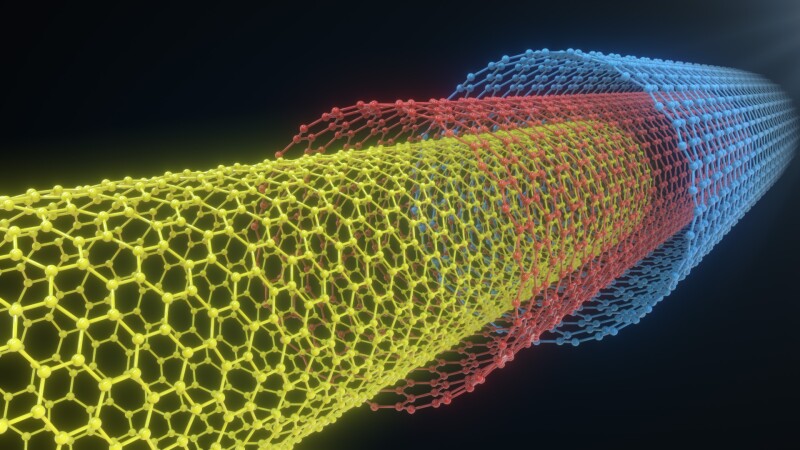

Characterized by their cylindrical structure, carbon nanotubes offer optimal properties for electrical conductivity, mechanical strength, and thermal conductivity—making them highly sought-after in various niche applications.

At this week’s Offshore Technology Conference (OTC) Asia in Kuala Lumpur, PTTEP disclosed advancements made with a prototype at one of its processing plants.

In OTC 34884, authors from the national oil company outline the deployment of a skid-mounted reactor that produced commercial-grade carbon nanotubes in higher yields and purity as compared with some conventional methods. PTTEP estimates its carbon nanotubes would fetch from $60 to $80/kg on the open market based on their purity and size, slightly above the current average prices of similar grades.

According to PTTEP, which references third-party market analysis, the demand for carbon nanotubes is expected to increase from approximately $6 billion currently to over $17 billion by 2032. Details not included in the paper include how much natural gas is required to be used as a feedstock to produce any given volume of carbon nanotubes.

The firm's success came after the researchers behind the project were forced to halt the pilot test from November 2020 to the start of 2022 due to the COVID-19 pandemic. PTTEP has listed this R&D project as one of its most key in achieving its long-term objective of attaining net-zero scope 1 and 2 emissions by 2050.

The core of the technology is the fluidized bed catalytic chemical vapor deposition process. This process involves feeding natural gas, nitrogen, and hydrogen into a preheated reactor, where the hydrocarbon gas's molecular bonds are broken.

This enables the free carbon molecules to rearrange into a hexagonal shape which in addition to being ideal for electron mobility gives carbon nanotubes a strength that surpasses steel by 100 times.

The resulting carbon powder has potential applications in batteries, electronics, and aerospace composites. PTTEP published test results showing that its carbon nanotubes could be used to build a supercapacitor with performance metrics roughly equivalent to those of commercial products.

Beyond the scope of the paper, PTTEP anticipates completing the front engineering phase for a more-extensive pilot production unit within the current quarter. The company is also exploring partnerships and licensing agreements to scale its carbon nanotube production into a viable business.

For Further Reading

OTC 34884 Flare Gases Conversion to Carbon Nanotubes (CNTs): Energy Storage Applications by S. Watcharasing, R. Nunthaworrarat, and T. Piromchart, PTT Exploration and Production Public Company.