The authors of the complete paper describe a case study in which, through proper understanding of failure mechanisms, characterization of shale strength anisotropy, and implementation of strength-anisotropy incorporated models, drilling high-angle wells through a challenging shale formation was deemed feasible. Following a pilot well’s success, a high-angle well was drilled using optimized parameters and higher mud weight (MW), achieving drilling with no nonproductive time (NPT).

Introduction

Although anisotropy is well understood, misconceptions about instability mechanisms creating reluctance to use of higher MW often lead to wellbore failure, NPT caused by hole‑cleaning issues, and a reluctance to drill high-angle extended‑reach-drilling wells.

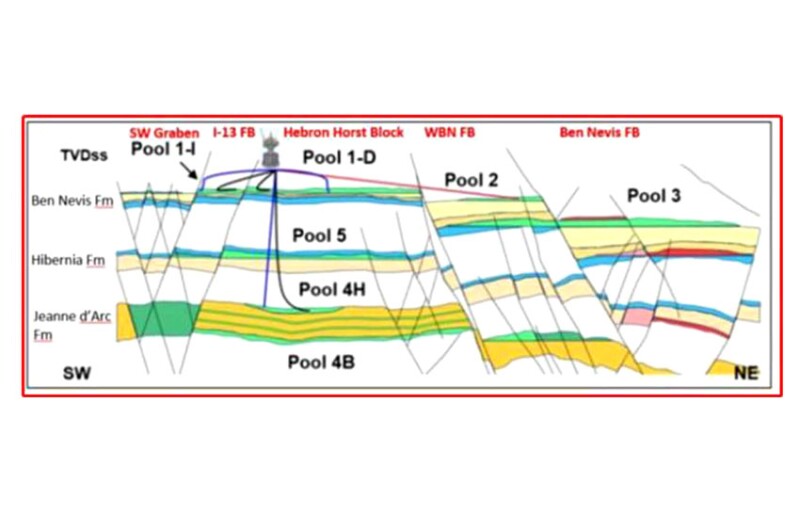

In the Hebron field in eastern Canada, a similar challenge arose. Previous drilling by offset operators in nearby fields suggested that wells through the Fortune Bay formation should not exceed 45° inclinations because of severe wellbore instability. The Hebron field includes three main producing formations: the Ben Nevis, the Hibernia, and the Jeanne d’Arc (JDA). Following initial shallower formation development, focus shifted to JDA formation development, which would require drilling the Fortune Bay shale at a high angle.