What if natural gas could be converted at the molecular level into hydrogen inside the reservoir and brought to the surface, leaving carbon dioxide and carbon monoxide permanently trapped below ground? A research team at the Skolkovo Institute of Science and Technology (Skoltech) in Moscow says it’s possible.

In a paper published in the academic journal Fuel in May 2024, researchers at Skoltech described laboratory tests of a thermocatalytic process to convert methane (CH4) into a gas mixture of hydrogen (H2), carbon monoxide (CO), and carbon dioxide (CO2).

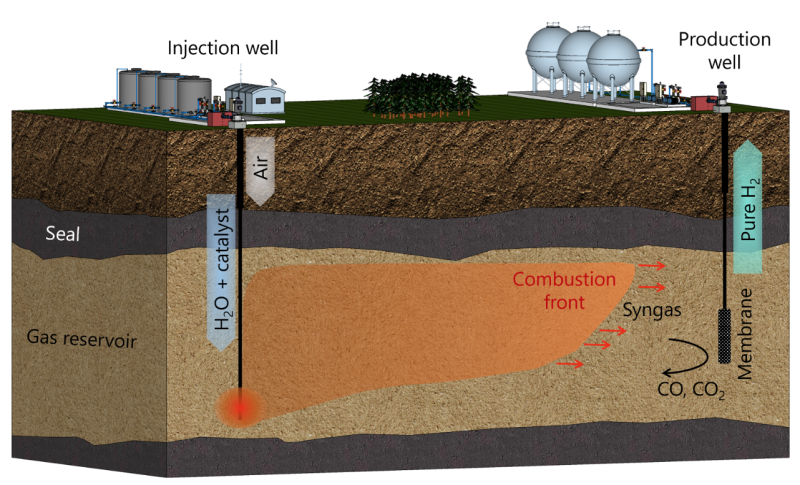

If developed at an industrial level, the process would enable hydrogen to be produced directly from a reservoir without releasing greenhouse gases into the atmosphere because carbon products would remain trapped underground.

Elena Mukhina, a senior research scientist at Skoltech Petroleum, wrote in the paper that her team has successfully converted methane via steam methane reforming initiated by in-situ gas combustion in a reservoir with zero oil saturation in laboratory reactors.

“In the experimental model, different rock porous media were utilized, and the process parameters such as temperature and the steam-to-methane ratio were varied,” Mukhina wrote. “The outcome reveals a range of variations, each yielding different concentrations of hydrogen produced depending on these adjustable parameters.”

Commenting in a Skoltech news release, Mukhina pointed out that the process is “based on well-established technologies that have not previously been adapted for hydrogen production from real gas reservoirs.”

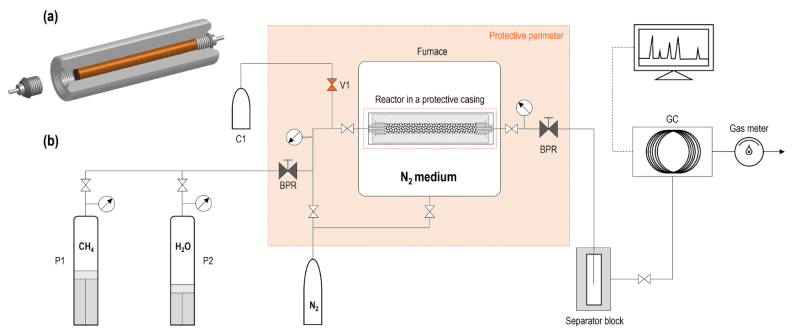

In the laboratory, researchers placed crushed rock in a reactor, pumped in methane along with steam and a catalyst, and then oxygen. Pressure inside was maintained at a level typical of gas reservoirs (80 times higher than atmospheric pressure), according to the paper published in Fuel.

Hydrogen is finally recovered from a production well through a specialized membrane that selectively permits the filtration of hydrogen while impeding other gases, including CO2, which remain confined within the rock.

So far, Skoltech researchers have converted up to 45% of total gas volume in a laboratory reactor into hydrogen at 800°C with an optimal steam-to-gas ratio of 4 to 1. The researchers chose 800°C as the ideal temperature because it is easily achieved in natural gas combustion and does not need to be artificially maintained, according to the published results.

In some experiments using porous alumina, the hydrogen yield reached 55%, but the higher efficiency is attributable to the fact that alumina is inert and so doesn’t react with surrounding elements.

In contrast, natural rock contains more active minerals that can react with the components of the gas mixture and affect the hydrogen yield, the research indicates.

Mukhina said that technologies are still in the research phase as applied to gas but her team’s evaluation of a similar oilfield technology has advanced to “preliminary numerical modeling” which if successful could lead to “a pilot launch (as) the next step.”

Porous media of oil reservoirs featuring residual oil saturation leads to a well-known process of oil upgrading, with hydrogen being one of the byproducts, the paper points out.

Calgary-based Proton Technologies has employed its own method to extract hydrogen from the mature heavy-oil field it operates in Saskatchewan, and hopes to prove its efficiency by licensing its technology to other operators.

An early leader in extracting hydrogen from hydrocarbon fields is Hydrogen Source AS, which holds active Eurasian patents on its proprietary process, "hydrogen generation from hydrocarbons subterrain (HGHS)". The company's patents originated in 2008.

In 2019, Hydrogen Source AS agreed to test its proprietary patented process of in-situ hydrogen production in an onshore depleted gas field in Russia's Volgograd region. The field candidate was selected by Hydrogen Source AS from a list of fields proposed by Lukoil. Hydrogen Source AS secured financing to contract in a 2-year project with Skoltech laboratory to make experiments according to Hydrogen Source AS design.

In 2021, a joint paper with Skoltech was published in Energies, presenting the results of this HGHS process project.

FOR FURTHER READING

A Novel Method for Hydrogen Synthesis in Natural Gas Reservoirs by Elena Mukhina, Pavel Afanasev, Aliya Mukhametdinova, Tatiana Alekhina, Aysylu Askarova, Evgeny Popov, Alexey Cheremisin, Skolkovo Institute of Science and Technology. Fuel (May 2024).

SPE 214036 In-Situ Hydrogen Generation Within Gas Reservoirs by Pavel Afanasev, Evgeny Popov, and Alexey Cheremisin, Skolkovo Institute of Science and Technology; and Evgeny Mitin and Viktor Darishchev, Lukoil-Engineering LLC.

An Experimental Study of the Possibility of In-Situ Hydrogen Generation Within Gas Reservoirs by Pavel Afanasev, Evgeny Popov, and Alexey Cheremisin, Skolkovo Institute of Science and Technology; Roman Berenblyum, Hydrogen Source AS; Evgeny Mikitin,

Eduard Sorokin, and Alexey Borisenko, Lukoil Engineering LLC; and Viktor Darishchev, Konstantin Shchekoldin, and Olga Slavkina, Ritek LLC.