Directional drilling has been used in oil and gas operations since the 1930s when onshore drillers employed the technology to reach offshore reservoirs. Over the years, technologies have been introduced to improve precision and control and at the same time have allowed multiple reservoirs to be produced through a single well, which reduces drilling costs and minimizes the environmental impact of the drilling process. In designing drilling plans, operators have considered economics when deciding whether to employ the traditional process of rotating the drillstring to control well trajectory or use more precise directional drilling techniques, but an either/or approach is not always the best one. The introduction of software that analyzes drilling conditions and determines the most appropriate drilling solution is changing the status quo, streamlining the drilling process and changing the playing field for drillers.

The Evolution of Directional Drilling

The widespread adoption of horizontal drilling from narrowly spaced slots on a centralized pad location has led to the introduction of complex wellbore geometry intended to maximize field development while minimizing geographical footprint. The growing need for precise execution of complicated well trajectories increased the demand for directional drilling expertise. Using a steerable bottomhole assembly (BHA) comprising a mud motor with a bent housing, an experienced directional driller can orient the bend of the motor in the direction prescribed on the well plan to steer the well on the intended trajectory in a process known as sliding. When the well trajectory is intended to remain relatively straight, the entire drillstring is rotated from surface in a process referred to as rotating.

Experience and research have shown, however, that the well trajectory is rarely straight during periods of rotation due to rotational tendencies, a combination of systematic and random influences from BHA design, drilling parameters, and geological formation characteristics that can cause a significant divergence from plan. Rotational tendencies, along with designed well plan deviations, often require sliding to ensure the well follows the planned trajectory.

All else being equal, it might seem that sliding should be applied across the board, but there are two reasons that sliding is not the default solution.

- Sliding generally produces a considerably lower rate of penetration than rotation.

- Elevated sliding percentage can introduce excess tortuosity and/or localized doglegs.

Sliding typically is viewed as an expensive operation that should be minimized, and historically, the directional driller has been tasked with determining when it is necessary to slide, the footage duration, and the direction based on projection estimates and drilling experience. This approach to decision making has helped reduce costs, but it is not a scientific methodology. The accuracy of the decision varies based on the experience of the directional driller, and it places the burden of the decision squarely on the shoulders of one individual.

The introduction of directional drilling advisory (DDA) software changes the picture by incorporating data into the decision-making process and providing a way to capitalize on the best directional drillers’ performance on every well drilled. With a DDA software system, the directional driller can focus on higher-priority tasks while the software enables more informed decisions that can improve the horizontal drilling process and should deliver a net decrease in the overall slide percentage on a given well.

The Evolution of Directional Drilling Advisory (DDA) Software

Inherent to the design of DDA software are the underlying algorithm principles. The few DDA software systems on the market today approach the slide recommendation problem from different vantage points resulting in varying levels of reliability and success.

One approach is to design an algorithm by having the DDA software mimic the decisions that a directional driller typically makes. This design could be described as a “directional driller in a box.” While this design is intended to speed up calculations and remove the burden from the directional driller, it will not lead to a reduction in slide percentage or performance gains.

A second approach is to use a Monte Carlo- type simulation to “try” hundreds or thousands of possible solutions at each new survey point to find the best set of slide and rotate instructions from the many tried. This approach typically eschews an overarching strategy to focus on just the next stand, often resulting in decisions that are suboptimal when viewed from the larger context of efficiently placing slides throughout the entire lateral section of the well. It is also computationally intensive, which can lead to a lag in the process workflow and costly deadtime on the rig.

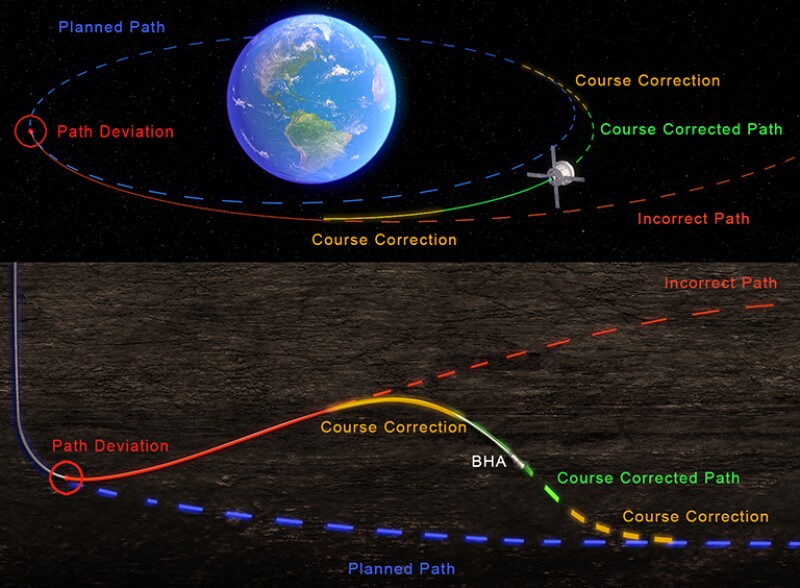

A third approach, adapted from the aerospace industry by Superior QC’s former NASA guidance, navigation, and control engineers, was used to design the HiFi Guidance DDA software system (Fig. 1).

When planning a mission, NASA scientists and engineers chart a planned trajectory for a spacecraft that is similar in function to the well plan designed by oil and gas operators and service companies. In both applications, a small percentage of the trajectory calls for planned steering events, while most of the trajectory is intended to be nonsteered. However, it is well understood that, in reality, external forces and unforeseen circumstances often require more steering than is originally planned.

In spaceflight, a steering event is conducted through rocket burns, which require the use of valuable fuel. Only a finite amount of fuel can be launched into space with the spacecraft, so ensuring that its usage is well planned is both mission and safety critical. Therefore, prior to launching anyone into space, NASA scientists spent years generating, analyzing, and simulating complex algorithms to ensure that the delta-v (summation of total velocity changes achieved through rocket burns) was as low as possible to minimize fuel consumption while still successfully achieving the mission.

A similar approach was applied to streamlining the directional drilling process by minimizing the amount of unplanned steering required. Through a true trajectory optimization approach, steering events are recommended only when they are strategically necessary. The foundation of the recommendation is built on real-time surface and downhole drilling data, the interaction between the BHA and the formation, and continuously updated trajectory estimates. The proprietary software system uses advanced artificial intelligence (AI) algorithms to refine the calculation of rotational tendencies and motor yield in real time to allow for reliable forward projections and optimized slide scheduling through each well section.

Quantifying Performance

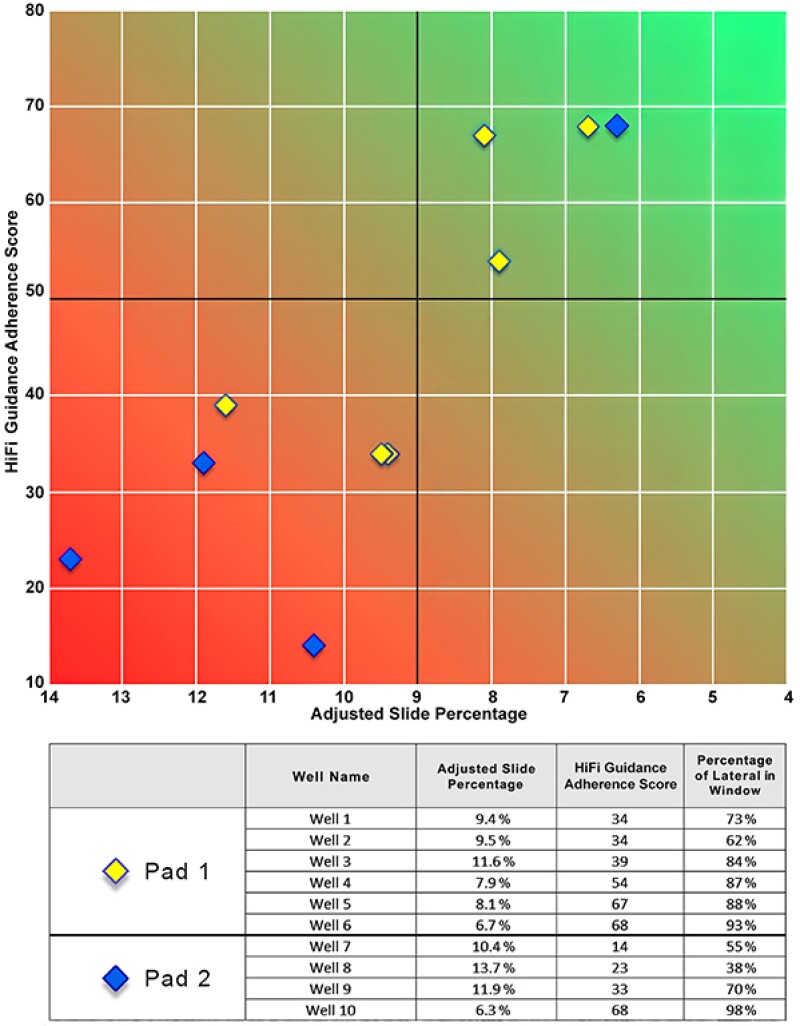

A set of field trials was conducted and analyzed in the lateral section of 10 wells on two pads to reach a better understanding of the efficiency gains that could be realized by applying HiFi Guidance. Prior to the real-time implementation of the software, several recently completed wells on the target rig line were analyzed to establish a baseline. To isolate the results of the field trials to reflect the impact of the software guidance alone, it was necessary to account for all the variables that could skew the results. These are variables that can increase or decrease the difficulty of achieving the target well objectives. For example, in certain basins and formations, faulting or intermittent stringers are more prevalent and can result in elevated levels of rotational tendencies. Another example is variations in the BHA design, which can generate different motor yields. A direct comparison of raw slide percentage from well to well would always favor the usage of a larger bend motor and a well with very low rotational tendencies. Therefore, as part of the analysis it was necessary to normalize for motor yield and rotational tendency. The normalization process resulted in an adjusted slide percentage that accounts for differences in motor yield between wells and for differences in average rotational tendencies to remove their impact on differences in slide percentage between wells.

It was important not only that the software was utilized on a well but to analyze how accurately its recommendations were executed. For this task, a HiFi Guidance adherence score was calculated using a point system for each stand:

- If rotation was recommended and no slide occurred—1 point

- If a slide was recommended and executed to within +/–25 degrees of target tool face and +/–3 ft in length—1 point

- HiFi Guidance recommendation was not followed—0 points

Using this logic, each stand received a 1 or 0 rating based on whether the software recommendation was followed. The ratings were averaged across all stands in the lateral to determine the percentage of stands on which the recommendations were accurately executed.

Analysis and Results

The case study results illustrate a clear correlation between the adherence score and the adjusted slide percentage. Fig. 2 shows that six wells yielded an adherence score of less than 50. These wells also resulted in the highest adjusted slide percentages. Conversely, the remaining four wells with adherence scores of greater than 50 yielded the four lowest adjusted slide percentages with Well 8 netting the highest adherence score of 68 and the lowest adjusted slide percentage of all 10 wells at 6.3%. The reduction of average adjusted slide percentage from 11.1% for wells with adherence scores less than 50 to 7.3% for wells greater than 50 resulted in significant time and spread cost savings for the operator on each well.

Several additional benefits of using this software system emerged from the case study. One of these is that in addition to reliably decreasing slide percentage, the software improved the amount of lateral footage placed in the target drilling window by an average of 27.8% when the adherence score was greater than 50. Using the software also delivered a less tortuous well, which decreased casing runtime and increased available hookload, making it easier to drill the well to total depth.

Transferring space-age technology to directional drilling has the potential to deliver efficiencies that save time and money. Results from the field prove the value of this proprietary software system, and continuing refinements enabled by AI will increase its value over time.

David Gutierrez is the senior technical advisor for Superior QC, a Patterson-UTI company. He has spent his entire career in the field of wellbore placement with roles as an MWD field engineer, drilling optimization engineer, and now senior technical advisor where he focuses on delivering precision wellbore placement to oil and gas operators through standardization and automation. He holds a master’s degree in structural engineering from the University of Nebraska. Contact Superior QC at info@superiorqc.com.