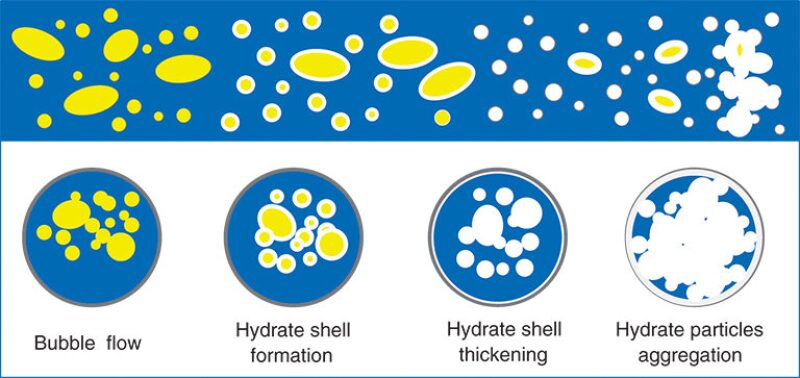

Current research into the risk of hydrate formation and blockage in pipelines is limited to prediction of hydrate formation. However, hydrate generation often does not lead to flow barriers. Hydrate growth and deposition rates are important to hydrate generation as a blockage risk. To help solve the problem of flow assurance in horizontal gas/liquid pipelines, this paper analyzes the risk of hydrate formation and blockage, aiming at various gas/liquid flow patterns and considering the phase distribution and interface distribution characteristics of different flow patterns.

Introduction

Hydrate blockage risk in transportation pipelines is one of the most important topics in the study of flow assurance.

×

Continue Reading with SPE Membership

SPE Members: Please sign in at the top of the page for access to this member-exclusive content. If you are not a member and you find JPT content valuable, we encourage you to become a part of the SPE member community to gain full access.