CO2

-

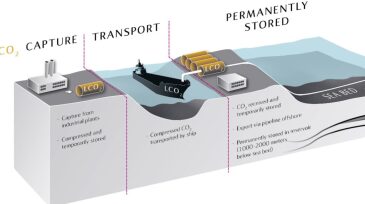

Gassnova has assigned Statoil to evaluate the development of carbon storage on the Norwegian continental shelf. This will be the first storage site in the world receiving carbon dioxide from several industrial sources.

-

A new material under development is highly effective at sieving carbon dioxide from natural gas streams and is also cheap and easy to make, according to researchers.

-

Has your company or organization invested in carbon offsets? Carbon offsets are proving an important tool for companies that want to reduce the effect of their carbon footprint.

-

This study explores the mechanisms contributing to oil recovery with numerical modeling of experimental work and investigates the effects of various parameters on oil recovery.

-

In a quiet industrial park in suburban Toronto, there is a machine that eats carbon dioxide (CO2) and spits out fuel. A world away, at a world-class research institute in Bangalore, India, engineers have developed a completely different technology to convert CO2 into industrial chemicals.

-

A floating gas-extraction facility was constructed to extract gas-laden water, separate the CH4 and some of the CO2, and reinject the degassed water, thus increasing the safety of the lake and simultaneously providing CH4.

-

Saudi Aramco saw a jump in production for a type of EOR that often takes years to see full benefits.

-

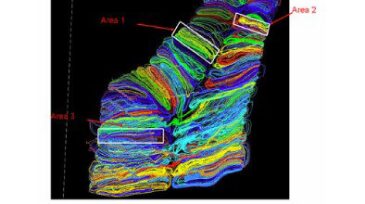

In this study, detailed petrophysical and geological field models focusing on the middle and lower members of the Bakken Formation were developed.

-

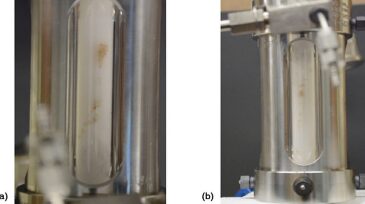

Carbon dioxide (CO2)/water foams are of interest for mobility control in CO2 enhanced oil recovery (EOR) and as energized fracture fluids or as hybrid processes that combine aspects of both processes.

-

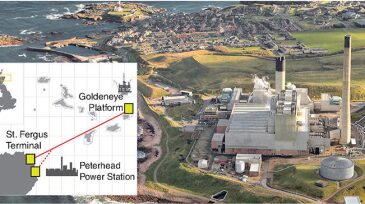

A major oil company is progressing a portfolio of commercial-scale carbon-capture-and-storage (CCS) demonstration projects covering an array of technologies that target applications of relevance to the wider oil and gas industry.