CO2

-

Winning innovators focused on environment, safety, and operational efficiency.

-

Although based on “intensity” and not “absolute” emissions, oil giants say it’s a step toward net-zero goals for 2050.

-

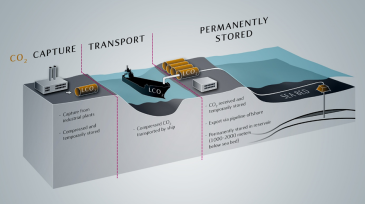

An independent study pegged the cost of the project at about $2.6 billion, 80% of which Norway’s government planned to fund. The ministry said there is uncertainty about Northern Lights’ benefits and that it could prove to be unprofitable.

-

A billion-dollar fund will be available for innovations in flare minimization, venting elimination, fugitive-emissions reduction, and complete combustion.

-

The company’s first report on global emissions shows that, while the US emits the most, Canada has the highest emission intensity and Norway has the lowest.

-

US energy-related carbon dioxide emissions declined by 2.8% in 2019 to 5,130 million metric tons, according to data in the US Energy Information Administration’s Monthly Energy Review. Carbon dioxide emissions had increased by 2.9% in 2018, the only annual increase in the past 5 years.

-

BP says it is firmly committed to achieving the ambitious target of net-zero greenhouse gas emissions over the next 30 years—even if that means producing less oil and gas.

-

The report card for unconventional oil and gas producers from a leading industry analyst is A+ for growth and F- for paying back investors.

-

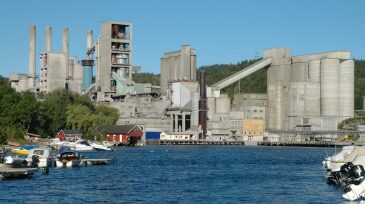

By transitioning from gas turbines to land-based electrical power for various platforms, the company hopes to reduce carbon dioxide emissions by more than 600,000 tonnes/year.

-

Between 2005 and 2015, energy-related carbon dioxide emissions decreased in 43 states (including the District of Columbia) and increased in 8 states. On a per capita basis, energy-related carbon dioxide emissions decreased in 49 states (including the District of Columbia) and increased in 2 states.