corrosion

-

Monitoring of corrosion in process pipelines has always been of paramount importance in ensuring plant-asset integrity. Similarly, steam traps play an important role in ensuring steam quality and, thus, the integrity of critical assets in the plant.

-

Saudi Aramco’s papers on new well technology offer glimpses at the challenges of developing its unconventional gas resources.

-

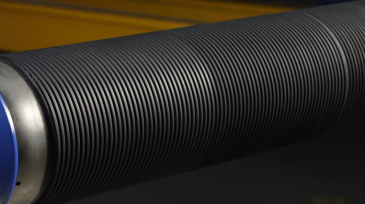

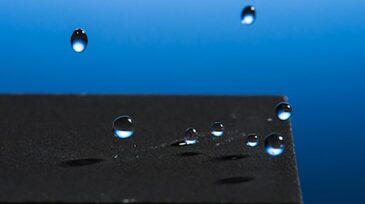

FLITE Material Sciences says that its unique lasering process can be used on just about any type of material to make it either repel or attract water and oil. For an industry that deals with a lot of both, the technology has many potential use cases.

-

The complete paper highlights examples of nonmetallic materials selection and qualification for upstream water-injection and producer and hydrocarbon wells and presents suggestions for future progress.

-

The complete paper presents the results of evaluation of laboratory and demonstration trials of HDPE liner to mitigate premature failures and prolong the run life of production tubing.

-

Material selection is a first line of defense against corrosion. This article reviews how to recognize pitting and crevice corrosion, as well as how to optimize tubing material selections for marine oil and gas applications based on the material’s PREN value.

-

The methodology is the industry’s first to address CUI. Along with DNV GL’s new technology, maintenance costs may be reduced by up to 50%.

-

Westcoast Energy revised its inspection practices following the 2018 incident. Its model used to predict crack growth did not take into account all uncertainties

-

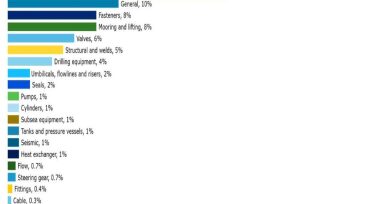

DNV GL researched over 1,000 failure cases to identify failure-prone components. The research is based on cases from its global network of labs.

-

This paper describes a material designed to interact specifically with highly corroded and weathered pipe to enable in-place application and refurbishment.