corrosion

-

The paper discusses the main factors affecting CO2 corrosion, provides an assessment of what to look for in major equipment, and details recommended material of construction and corrosion mitigation/control methods.

-

With the huge amount of water injection in the industry, the need is paramount for a more scientific approach to materials selection for tubing, especially CRAs. Software-based predictors similar to those developed for CO2 corrosion would improve the economical choice of CRAs.

-

Corrosion inhibitors are often the first line of defense against internal corrosion, and effective mitigation relies on proactive monitoring and management of these inhibitors to allow for regular feedback and dose adjustment.

-

Siemens and GE are among the companies discovering the power of an open-source innovation community to offer solutions for significant oil and gas industry challenges, such as improved corrosion monitoring.

-

During the dismantling and removal of fire-water-pump columns of superduplex stainless steel barely 1 year after plant startup in a redeveloped brownfield offshore Nigeria severe localized pitting corrosion was observed in the columns. This paper explores the findings and identifies the reasons.

-

With these synopses of technical papers from OnePetro you can join the author for conferences in Kuala Lumpur, New Orleans, and Lagos, all while sitting in your chairs and without any travel expenses.

-

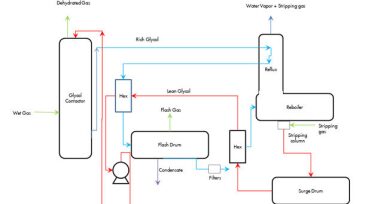

The paper discusses dehydration performance of two units in two plants—with preinhibited glycol/antifoam/pH adjuster blend vs. neat glycol with periodic injection of antifoam and pH-adjuster inhibitors. The insights present an opportunity for significant operating and capital costs reduction.

-

A consortium of organizations has set out to tackle one of the more enduring challenges in the North Sea: the nondestructive testing (NDT) of corroded pipes under insulation and engineered temporary pipe wraps.

-

General Electric has launched a subsidiary to develop and sell the use of flying, crawling, and swimming drones for inspections in the oil and gas industry, among others, the company announced.

-

Oil and gas producers in the Gulf of Thailand face unique technical challenges. This review of papers illustrates some of the innovative solutions used in the region.