UK Continental Shelf

-

The asset combination is structured under Eni’s “satellite model,” which Eni has deployed successfully with similar upstream joint-venture deals in Norway and Angola.

-

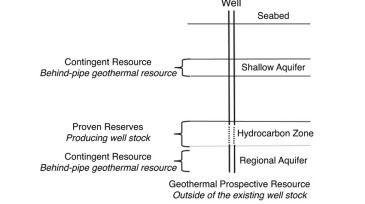

This paper provides an overview of a geothermal assessment project completed to assess geothermal energy resources in and around an operational high-pressure/high-temperature field on the UK Continental Shelf.

-

A drop in the number of wells drilled on the UK Continental Slope is concerning as many fields in the mature basin are reaching the point of production cessation.

-

The multiyear, $20 million-plus contract is for a well abandonment campaign in the Balmoral area in the UK central North Sea.

-

First production from the UK North Sea gas field is expected in the second half of 2025.

-

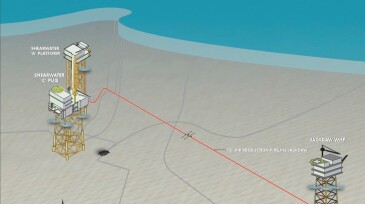

Shell’s revised Jackdaw development plan has been approved by regulators who had rejected its original plan last year.

-

The UK’s Net Zero Technology Centre looks to pave the way for new well P&A technologies to be tested, trialed, and brought to market quickly.

-

Organizers of the Oil & Gas Authority’s decarbonization competition are looking for ideas to bring electrification and an integrated energy basin closer to reality.

-

The latest agreement between Wood and Equinor will begin January 2021. The contract follows recent agreements between the two companies for the Breidablikk development in the Norwegian Continental Shelf.

-

For the seventh straight year, the regulatory body has found offshore operations continue to improve based on an efficiency model developed in partnership with the SPE.