The energy transition momentum currently sweeping through the oil patch has prompted corporate rebranding, heightened investment in renewables and a genuine sense of responsibility over the amount of harmful gases that industries release into the air. Beyond emission reductions, carbon capture and storage (CCS), viewed as a novelty by some just a few short decades ago, has leaped to the forefront of greenhouse-gas management solutions, with big players committing big money to projects aimed at ensnaring, transporting, and burying the waste deep underground.

Last April, ExxonMobil unveiled plans for a $100-billion CCS hub for the Port of Houston. Dubbed the CCS Innovation Zone, it is expected to be a public-private partnership that will attract participation and funding from companies and government entities. In September, the supermajor went on a buying spree in the shallow-water US Gulf of Mexico (GOM) as part of federal Lease Sale 257. It was the apparent high bidder on 94 tracts to the tune of just under $15 million. While these are presently structured as hydrocarbon leases and the company has kept mum on its motivations, the move was almost certainly to gain access to coast acreage that could potentially serve as subsurface storage locations for the proposed Houston hub.

Following the lease sale, Spanish operator Repsol said it had partnered with US independent Cox Oil to jointly explore CCS opportunities on the private operator’s shallow-water GOM acreage. Under the terms of the agreement, the consortium will share technical knowledge and resources to evaluate potential projects that would combine the offshore expertise and operations of Cox Oil with Repsol’s technical knowledge and global experience with CCS projects.

Then there is Talos Energy. The Houston-based independent has jumped feet first into the CCS pool, announcing a pair of US-based projects with designs on making carbon capture a steady revenue contributor over the coming years.

Early in 2021, the company evaluated various green businesses where it could make a difference—and a dollar—including carbon capture, but also wind and wave energy. At that time, CCS was more of a peripheral discussion, but as the company took a closer look it became apparent that its skill set and investment profile lined up best with a role in carbon capture. By April, the company was presented with the opportunity to propose a CCS solution solicited by the State of Texas’ General Land Office (GLO).

“We started evaluating the geology, all the possibilities,” said Bob Abendschein, executive vice president of operations for Talos. “Knowing that CO2 has been in oil and gas DNA forever and when looking at our staff’s previous experience, we’ve done a lot of CO2 injection and EOR [enhanced oil recovery]. When you start looking at the emissions scope along the Gulf Coast, it is very large. Then you look at the storage potential along the Gulf Coast, and it is phenomenal. It’s 300 years of storage at current emissions levels. At a high level, carbon sequestration makes good macroeconomic sense.”

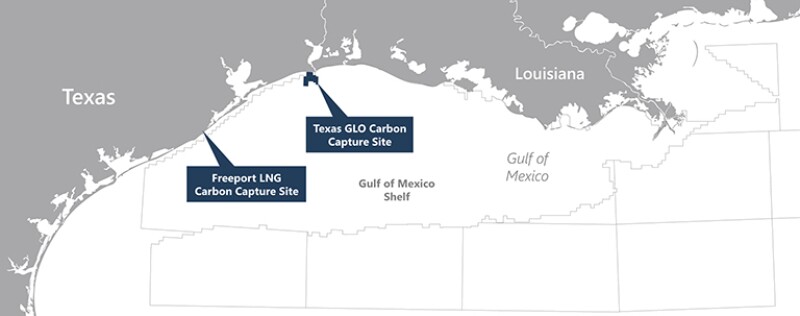

Talos and its partner Carbonvert won the bid for the GLO acreage, which is situated near the city of Port Arthur in Jefferson County, Texas. The project site encompasses a total land area of more than 40,000 gross acres and is located offshore in Texas state waters in the GOM. It is 100% covered by Talos’ existing seismic database and is near a large concentration of industrial emitters along the Texas and Louisiana Gulf Coast. Based on the operator’s preliminary understanding of the rock and fluid properties of the saline reservoirs of the site, Talos expects it can ultimately sequester about 225 to 275 million metric tons of carbon dioxide from industrial sources in the area. Talos will operate the project.

Offshore Texas Miocene CO2-capacity estimates are high compared to estimates from similar areas for many other states and countries, according to a recent paper (OTC 29268) from the University of Texas Gulf Coast Carbon Center. The Miocene of the northern GOM is well documented and well understood, which increases its CO2-sequestration potential. Multiple stacked reservoir sandstones with high porosity and permeability provide very large pore volumes for potential CO2 injection and storage.

The Steps Required

For a complete CO2 cycle, there are three critical elements, according to Nikhil Joshi, director of innovation and technology at Talos. It must be captured (separated from gas and then compressed), transported (if required from the capture site to the utilization/storage site), and either utilized or stored. Much of the attention is usually placed on the capture piece of the project, which is an important aspect, but without transport and storage (or utilization), it’s an incomplete picture.

Several capture technologies are available, but the most used and most mature is amine absorption, in which there are primarily two components: (1) An absorption counter-current-flow tower where a gas mixture containing CO2 flows from bottom to top and an aqueous amine mixture flows from top to bottom. As the amine contacts the CO2, it absorbs it from the gas and leaves from the bottom of the tower. Thus, the gas leaving the top of the tower is without CO2. (2) The amine liquid with CO2 absorbed is then heated to release CO2 in gaseous form, leaving behind the amine which contains more water from the first stage. The water and amine are then separated in another tower, leaving behind water to dispose and amine to be recycled to step one.

“The capture technology using amine is mature but expensive,” explained Joshi. “The cost of capture does not allow large-scale deployment of that technology. There are several variations being studied: more-effective solvent to capture CO2, lower energy consumption configurations including cryogenics. Other technologies such as membranes are appropriate for special cases—higher-CO2 content to be separated, relatively lower mass flow, etc. The world recognizes that better technology and large-scale deployment is essential for CO2 capture to be adopted across all industries for decarbonization.”

The Jefferson County storage site is large with a very high capacity. Much of what the final project will look like will depend on the appetite of Texas/Louisiana border emitters to be early movers.

“Each organization that has CO2 emissions has their own thoughts,” said Joshi. “CO2 will need to be separated and likely done locally at the site of the emissions. Once the CO2 is separated, it will be connected via a network of pipelines from each facility to a header system transporting it to the injection wells that will be located offshore.”

Forging Carbon Partnerships

Following the GLO award, Talos teamed up with Storegga, a UK-based player in CCS and the lead on the Acorn partnership with Shell, ExxonMobil, and Harbour Energy. Acorn is a leading UK CCS and hydrogen project expected to be operational by the mid-2020s. Talos and Storegga created an exclusive joint venture this past June to source, evaluate, and develop CCS project opportunities on the US Gulf Coast and GOM, including state and federal waters offshore Texas, Louisiana, Mississippi, and Alabama.

In October, Talos also teamed up with contractor TechnipFMC in a long-term strategic alliance to develop and deliver technical and commercial solutions to CCS projects along the US Gulf Coast. One month later, Talos announced its first project with Storegga—a letter of intent with Freeport LNG to develop a CCS project at the liquefaction plant on the Texas coast.

“Freeport LNG desired a way to eliminate its CO2, so Talos and Freeport worked side by side to develop a potential project,” said Abendschein. “This won’t be a hub-class storage site in size; however, it is expected to be the first commercial application of CCS along the Gulf Coast. We think we can get that up and running by 2024, primarily contingent on the permitting process.”

Talos believes the Freeport LNG CCS project could prove a repeatable model for numerous other areas and customers along the US Gulf Coast with similar emission profiles.

“One of our advantages is that the shallow waters of the Gulf Coast are our backyard. We’re one of the largest and most active companies operating in that region today. Also we’re very focused on commerciality and costs, and can optimize the economics of these projects relative to other players. Our skill sets will serve us well as we grow this business and focus on potential customers.”

Companies interested in CCS in the US do have tax credits working in their favor. The US is offering subsidies to accelerate carbon capture—Section 45Q in the Internal Revenue Service’s tax code. The credits currently offered range from $35 per ton if the gas is used for EOR or $50 if it is permanently sequestered. Those amounts could rise to $50 and $85, respectively, if the current spending bill currently before the US Senate is passed.

“Carbon capture and sequestration will be a real, tangible contributor to the emissions reduction story in the future,” said Abendschein. “The question is how do we incentivize the petrochemical company that has a marginal CO2 footprint to get the necessary equipment in place so that the addressable market is sufficient to encourage broad CCS development.”

Setting Up for the Long Haul

Backing its commitment to the CCS business, Talos hired Robin Fielder as the company’s first executive vice president, low-carbon strategy, and chief sustainability officer. Under the newly created role, Fielder will serve as the lead executive for Talos’ rapidly growing CCS business as well as oversee all ESG and sustainability initiatives and reporting. Fielder most recently served as president and chief executive officer of Noble Midstream Partners LP, a Chevron Corp. company, following its acquisition of Noble Energy.

The appointment confirms Talos’ commitment to finding CCS solutions and brings a better understanding of the carbon value chain. The company views CCS as a natural extension of its oil and gas business sharing many of the same operations such as drilling, midstream, and disposal and views its experience in offshore project management and development as key components to success.

“Who’s going to solve this problem?” asked Abendschein. “Across all sectors of the economy, there is nobody better positioned to solve carbon capture than the oil and gas industry. We have experience in all the required skill sets to execute safely and economically. We’ve been doing it for decades. Our team has experience managing carbon, CO2 floods, and other legacy carbon applications. You must know your geological model, understand where the plume is going, and do reservoir simulation.”

Talos’ ambition to be a CSS player begins in the US but is not necessarily relegated to the region going forward. Part of the allure of aligning early on with international players was, at least in part, to ease entry into new areas by leveraging their partners’ experience in those areas. While the company’s current model is to operate its initial CSS assets, that could change if the right project with the right partner emerges.

“That’s one reason we picked Storegga and Technip,” said Abendschein. “Let’s be realistic, it’s getting that entry point into those countries, and that can be facilitated by international partners. We want to operate to start with, but that doesn’t mean we won’t be participating in non‑op as well.”

For Further Reading

OTC 29268 What Offshore CCS Will Look Like in the Gulf of Mexico–Perspectives from Texas by T.A. Meckel, S. Hovorka, and R. Trevino, Gulf Coast Carbon Center–The University of Texas at Austin.