PetroRio is a young, Brazilian independent oil producer whose acquisitions tend to raise the same question: “How do you make money from old brownfields? That is the question we have always heard,” said Iuri Rossi, subsea coordinator at PetroRio.

The answer has existed since small companies began buying the discards from big oil companies looking for the next giant field—cut costs and invest some of the earnings to extend the productive life of the existing platform

At this year’s Offshore Technology Conference (OTC), Rossi provided an example by describing how PetroRio acquired two nearby fields in the Campos Basin to create a single, profitable unit (OTC 31900).

It began with the acquisition of the Polvo field (Portuguese for “octopus”) in 2016, shortly after the launch of the privately owned company. The purchase from BP included a floating production platform and a costly leased floating, production, storage, and offloading (FPSO) vessel capable of handling many times the 8,000 B/D output of the aging field.

The value of the Octopus field became apparent only in 2020 after the company made two more acquisitions: First, it purchased an FPSO on the nearby field Tubarão Martelo (Portuguese for “hammerhead shark”); later that year it also bought the field.

Those deals offered a solution—build a pipeline from the Polvo platform to the Tubarão Martelo FPSO and dump the leased FPSO.

The $45 million spent to marry the field saved $50 million a year, generating cash to support a future that will include more drilling, Rossi said. The cost-cutting moves also included small deals such as buying an obsolete drilling rig for $1.00, then getting it running again and using it to work over wells.

“We bring a new mindset; so, we say, ‘let’s try it,’” Rossi said.

New thinking and more investment in the Campos are what Brazil needs as Petrobras and other big companies sell off smaller holdings in the rich basin that made the country a major oil producer before the ultradeepwater pre-salt play in the Santos Basin eclipsed it.

But there is a lot of oil left in the Campos. Equinor reported that its partnership with Petrobras has a goal of adding 1 billion bbl of production to the Roncador field alone (OTC 31729). Still, at age 40 it is a mature play, along with the North Sea and the US Gulf of Mexico (GOM).

Petrobras recently announced it would allocate $5 billion to work in the Campos from a $20-billion fund to provide the infrastructure needed to promote offshore development.

“The Campos Basin plays a very strategic role for Petrobras in the future. Two-thirds of the production [there] in 2026 will come from investments made right now,” said Eduardo Bordieri, executive strategy manager for Petrobras, while presenting a paper on the future of the Campos at an OTC session (OTC 31883).

While several papers focused on the Campos, the session also offered reports on field-extension work in the GOM and Angola where a common theme was dealing with producing fields reaching the end of their 20-year design life.

The ideas in papers from Occidental Petroleum, TotalEnergies, and Equinor ranged from streamlining the painstaking effort needed to extend the life of aging platforms to the continual search for incremental production gains.

“Leveraging assets is more and more important for us,” said Clay Thompson, director of operations in the Occidental Gulf of Mexico business unit. “We have very seasoned assets, and we want to get everything out of them we can.”

Circa 2000 Problem

The seasoned assets he mentioned are eight of their 10 platforms in the GOM that began producing between 1999 and 2005, the period Thompson described as the “greenfield development era.”

Occidental’s paper looked at extending the life of its oldest offshore field, Marlin, which started producing in 1999, and describes the options for other older fields added with the acquisition of Anadarko in 2019 (OTC 32122).

While that presentation and others focused on the work needed to win permission to extend production beyond the original design-life prediction, the Occidental paper pointed out that the endpoint for these fields is uncertain. The choice between investing in older assets or decommissioning them depends on things it cannot control such as oil and gas prices, the ingenuity of its technical people, and the willingness of the company’s executives to hold on to older assets.

Getting the most out of an asset may include moving a platform to a more-productive field—an idea that appeals to Thompson, who points out Occidental’s offshore fleet includes eight spars that are built to last.

“A spar is a really robust structure with a lot of reserve strength,” he said, adding “I can see differences in the TLP (tension-leg-platform) vs. spar life extensions.”

That added strength is a positive when they calculate the field life lost due to decades of structural fatigue and corrosion.

Although Thompson didn’t offer any examples of platforms marked for a move, Occidental owns two fields—Nansen and Boomvang—that offer an opportunity like Polvo and Tubarão Martelo. The fields are about 8 miles apart, which is short for a tieback, and each field’s platform is capable of handling 40,000 BOPD and 200 MMcf/D of gas—the peak output from fields long past their prime.

Old and Rich

The reservoirs in the Campos are so huge that even after decades of production, they can still justify large investments.

Petrobras will be installing three large FPSOs to replace nine aging ones. Bordieri played up the “huge water-treatment capacity” of the new ones—a reminder that the oil remaining in the reservoirs is flowing with a lot of water, which makes the oil output dependent on the water-handling capacity.

Gabriel Góes Monteiro said during an OTC presentation that Equinor evaluated strategies to limit water production in the Campos, particularly inflow-control devices. A subsurface leader for Equinor, he offered examples of these devices proving to be a good investment, but not always.

A point he made more than once was that the search for field improvements needs to be a continuous process and include the subsurface team, which is also continuously updating its reservoir models looking for opportunities to improve production.

At Roncador, the partners are looking beyond the original reservoirs in sandstone to carbonate layers and below the thick layer of salt, where they estimate there may be another 200 million BOE. They are planning an exploration well that will penetrate the carbonate layers and evaluate the pre-salt, in hopes that the Campos will rival the Santos.

The Database Challenge

There is remaining life in old iron that has reached the end of its design life, but years of work may be required to convince regulators and vessel-rating agencies that a platform has 5 or 10 more years of hard use in it.

The descriptions of the process presented at the session explained why it can require 3 years to complete.

When TotalEnergies began working on extending the life of Girassol, one of the fields that was part of Angola’s greenfield boom 20 years ago, the big question in their minds was, “What do I want to look at?”, said David Maimaran, a deepwater petroleum architect for the company.

Answers to that question offered that day amount to a stiff test of corporate recordkeeping and database management.

“There is a huge amount of data you need to collect,” Maimaran said, which includes records related to maintenance, materials used, inspections, and safety performance.

To make sense of this mountain of old and new data, TotalEnergies conducted 40 specialized studies to find information in those numbers and make fixes.

When evaluating the future of Girassol, it had the advantage of being involved in the field dating back to its discovery in 1993, which is often not the case.

The fields Occidental bought from Anadarko generally went through multiple hands. An extreme example is the Horn Mountain field in the GOM. It was discovered by BP and Occidental and was subsequently owned by Plains Exploration and Production, Freeport-McMoRan, and Anadarko, which was acquired by Occidental in 2019, according to Offshore-Technology.com.

Occidental’s authors explained in OTC 32122 how multiple owners made the job harder. “It became evident early in the project that uncovering the details of prior interpretations and evaluations was problematic due to multiple company mergers.”

Finding original field data such as production records required figuring out how different operators organized their databases, archived geological data, and decided which records to keep. Determining this was made more difficult by the “absence of past team members,” according to the authors.

They added, “The data mining process took days to filter, organize, and prioritize into project workflows. In some cases, the data mining was unsuccessful, and the project needed to be rehabilitated from the ground up, resulting in a change in project management style.”

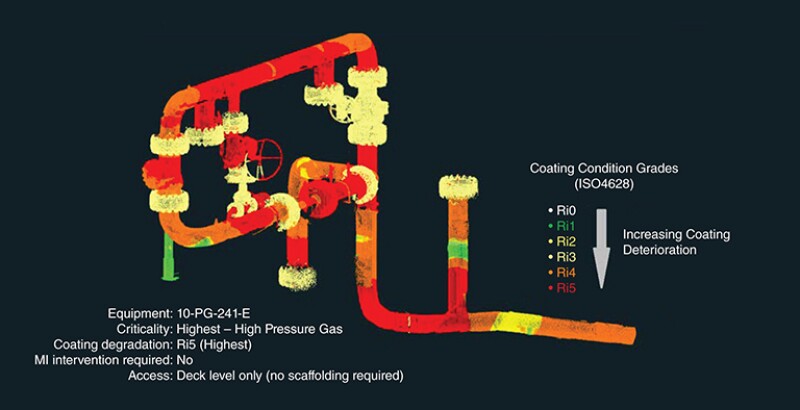

After that difficult dive into the data, it was time to look at the equipment itself. “The inspection program is where we bear the brunt of the cost and the risk,” said Thompson, who noted that regulators have not defined how that should be done.

That vacuum may have an upside for operators that are experimenting with new technologies to speed work and reduce the number of people needed because “we cannot have an army of inspectors offshore all the time,” Thompson said.

For example, Occidental has been testing a method to measure corrosion losses inside pipes using a method known as photogrammetry.

TotalEnergies and Occidental reported using drones to speed equipment observations by flying around inside ballast tanks, or in some cases, under water.

Maimaran said Occidental used drones to inspect 12 ballast tanks in 5 days; otherwise this could have taken months of work by people in those risky spaces. Doing that in oil storage tanks will require drones built to ensure they will not spark an explosion.

The use of drones as tools is spreading, as evidenced by videos shown at another OTC session on new inspection technology, where a drone maker said both flying and swimming devices have been tried.

Those doing the work said this process can head off in unexpected directions. The endpoint looks different when oil is selling for more than $100/bbl on fears of short supplies than it does at $35/bbl amid a global glut. This is only one of many variables.

“You need to keep flexibility because you know there will be evolution of the scope,” Maimaran said.

For Further Reading

OTC 31900 Private Cluster and Revitalization Mature Fields in Brazil by Diego Resende Teixeira Cotta, Jean Carlos Calvi, and Iuri Rossi Simões Carvalho, PetroRio.

OTC 32122 Maximizing Value From Mature Assets in Deepwater Gulf of Mexico by Clay Thompson, Manoj Jegannathan, and Natasha Jeansonne, Occidental Petroleum Corp.

OTC 31729 Revitalizing Mature Fields Through IOR by MariaClara Costa, Gabriel Góes Monteiro, and OlePetter Bjørlykke, Equinor.

OTC 31883 The Campos Basin Case: Unlocking Value From Mature Offshore Brazilian Assets–Petrobras by Otavio Diniz Lameira, Denis Krambeck Dinelli, Eduardo Bordieri, Petrobras et al.