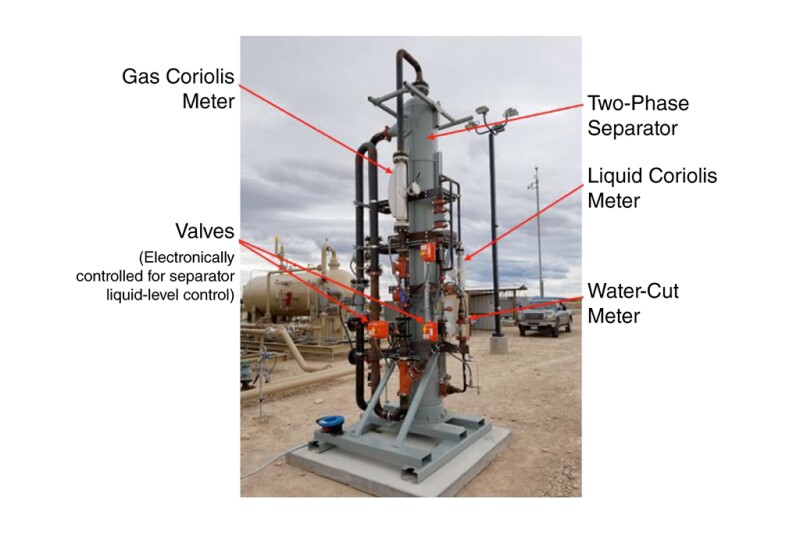

The complete paper highlights well-test challenges, provides an overview of common problems, and describes the broader impact of inaccurate or infrequent well tests, with a focus on production testing of wells in the Permian Basin. Many of these challenges, however, apply to onshore oil and gas fields around the world. To overcome the measurement challenges in a cost-effective manner, the industry has taken multiple approaches to create various inline test devices with limited success. The authors introduce a measurement system that is agile for transport and can be installed anywhere with a small footprint while delivering reasonably accurate results.

Introduction

Measurement-system design included the following requirements:

- Able to measure oil, water, and gas flow rates with reasonable accuracy

- Agility allowing the system to be moved rapidly and easily by using a trailer behind a work truck

- Installable and operational within 6 hours

- Maximum 8×8-ft footprint

- Must run standalone or in series with any other measurement system for validation testing

- No requirement for additional infrastructure—capable of operation under its own power and communication with cellular or satellite phones and modems

Theory and Methods

Industry Practices: Importance of Accurate Well Tests. The standard test requirement for regulatory reporting in most provinces and states in North America is two 24-hour well tests per month.