More than three dozen oil and gas producers are working together to solve one of the grand challenges faced by all in the increasingly global unconventional sector. That is the ability to better predict tight-oil and -gas production using rate transient analysis (RTA).

Considered an “unconventional diagnostic” when first introduced in the 1970s, RTA relies on fluid rates and flowing pressures to inform engineers on what their reservoirs will ultimately yield. Unfortunately, the low permeability of tight rocks and a myriad of dynamics stemming from hydraulic fracturing have undercut the simplicity of the tool.

This has given rise to arguments that RTA is not a fit for unconventional reservoirs. But a joint industry project with 37 operators from around the world is betting against that notion.

Those taking part represent the biggest and most active shale plays in the US—a list that includes Apache Corp., BP’s shale unit BPx, Devon Energy, EQT, Hess Corp., and Ovintiv.

Others hold assets in Canada’s Montney and Duvernay formations, Argentina’s Vaca Muerta Shale, and the emerging Jafurah tight-gas basin that Saudi Aramco is in the early stages of developing.

The organizer behind the joint project is petroleum engineering software and consultancy Whitson. The Trondheim-based firm said the client consortium is likely the largest of its kind to focus squarely on improving RTA for tight reservoirs.

In October, the multinational group wrapped up its first phase of study with a set of best practices and the release of new add-ons for Whitson’s software service. Why this might evolve into a notable development is because the deliverables are all designed to help standardize a recently debuted alternative called the numerically enhanced RTA workflow.

Introduced by reservoir experts at Houston-based Apache and IHS Markit, this "enhanced" version of numerical RTA has caught the industry’s attention for its ability to account for the effects of multiphase flow in tight wells. The first details about the approach were shared with the industry in 2020 in URTeC 2967.

Whitson reports that a newly established workflow for numerical RTA created with operator clients delivers consistent well analysis in seconds to a few minutes, and importantly, was proven to work across their disparate geologies.

Assembling a Trifecta

Carlsen, a reservoir engineering expert, described the overarching goal of the joint project not as a mission to discover a panacea for RTA but one designed to fill in its big gaps with some recent innovations.

“What we’ve been successful at through the joint industry project is getting the new tools ready so that the workflows can be easily used and in standardizing them for a wide range of wells found in every single unconventional basin in the world,” he said.

He noted that as the project continues into its second year it is zeroing in on the production effects of well-to-well interference and the impact of injection water as it returns during well flowback.

In addition to furthering numerical RTA, these next objectives will mean building upon two other techniques created just within the last few years: multiphase flowing material balance (without relative permeability), developed by experts with Cimarex Energy (now Coterra Energy); and fractional RTA, developed by experts at Chevron and Acuna Consulting.

“All of these technologies are definitely providing something new to the industry and solutions to some of the inherent problems that have been identified in the field,” said Carlsen.

But if the sum is greater than its parts, he points out that the end result of the joint industry project will not be a “holy grail” equation or come in the form of a singular RTA methodology. Instead, it will be a mélange of the aforementioned innovations.

The work underway today can be boiled down to an attempt to turn three separate diagnostic variations into a system that Carlsen explains will deliver “different key outputs that put together the big picture when you interpret these wells.”

One way to understand that big picture is to look at what each of the component parts bring to the table.

Numerical RTA solves for multiphase flow effects which are not only ubiquitous in all oil and condensate wells but considered major influencers of how those wells will perform over their lifetime.

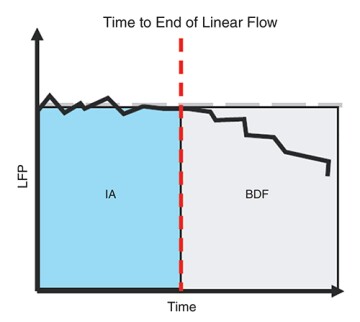

In summary, it begins with a horizontal flat line representing infinite- acting, linear flow. As the line trends down, the well is entering a transitional or boundary-dominated flow regime. Engineers can use the magnitude of the line’s deviation to acquire their linear flow parameter.

Multiphase Flowing Material Balance (MFMB) without relative permeability addresses the fact that permeability cannot be directly measured in tight reservoirs.

The resulting output is considered a more reliable estimate of contacted oil and gas in place which is used to constrain production forecasts.

An explanation of the methodology was published last year in URTeC 3718045 by former Coterra employees that have since joined Whitson.

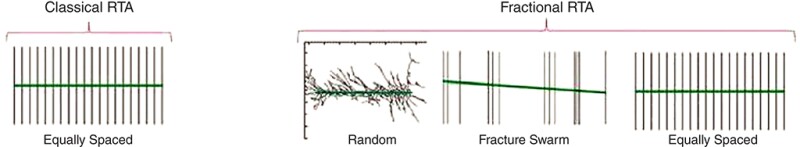

Fractional RTA is considered one of the industry’s best attempts to model a transitional flow regime. It acknowledges what detailed subsurface studies have shown in recent years, which is that hydraulically fractured horizontal wells do not result in symmetric and equally spaced fractures, but fractures of varying geometries/morphologies.

These complex fracture networks will thus exhibit different types of flow regimes all at once. The concept was introduced in 2016 in URTeC 2429710, and the most recent overview of the workflow was presented last year by Chevron and Acuna Consulting in URTeC 3724391.

Regarding how all the various elements may be combined, MFMB provides an output on contacted hydrocarbons that in turn helps improve the accuracy of the interpretations made using numerical RTA.

Next is the workflow for fractional RTA. Because it already features a numerical model, the task facing the joint project is to make it compatible with numerical RTA.

“They are all very intertwined and provide direction to one another. So, you wouldn’t want to run just one of them when it’s very easy to run all of them at the same time” thanks to the speed offered by cloud computing and numerical modeling, explained Carlsen.

Multiphase Flow Matters

Numerical RTA became the joint project’s initial focal point following the publication of URTeC 2967. Among other things, the paper highlights the results of a blind study pitting classical RTA techniques against Apache’s original workflow for the new method.

A group of 10 engineers from the shale producer were asked to estimate flow parameters and the volume of original oil in place from a pair of Permian wells with 19 and 24 months of respective production data.

The divide between the answers was stark.

Error rates for those using a classical RTA workflow went beyond 100% in some cases vs. an average of less than 10% for those using numerical RTA.

Carlsen has coauthored a pair of recently published SPE papers on the use of numerical RTA (URTeC 3718584, SPE 210420) and considers it to be a significant breakthrough due to the outsized impact multiphase flow has on the shale sector.

“What’s unique about unconventional reservoirs is that at least 90% of them are extremely complex when it comes to multiphase flow effects and the importance of pressure-volume-temperature (PVT) estimation,” he said.

A perfect example Carlsen offered where understanding multiphase flow effects “is crucial” is in the Permian Basin where “most of what’s being drained there is either black oil, volatile oil, very critical fluids, or condensates.”

At the heart of the matter, at least as far as numerical RTA is concerned, is a one-two punch of sorts that faces each of the fluid types Carlsen highlights.

First, as bottomhole pressure falls below the saturation point, the multiphase flow profile of a liquids-rich tight well faces an inevitable evolution. This is exacerbated by the aggressive drawdown strategies so often prescribed to horizontal shale wells.

And one big conclusion Apache and others have reached is that as that saturation point is crossed, and more and more gas is coming out of solution, the classic versions of RTA breakdown.

This means an engineer using them will not be able to accurately assess whether their well remains in an early flow regime—i.e., linear, infinite-acting flow—or is exhibiting the behavior of a well in its middle or late-stage regime—i.e., transitional or boundary-dominated flow, respectively.

To illustrate the point, Apache shares in its 2020 paper a test case that used classical RTA to pick the end of the early-flow regime from the data on a Permian well. The pick was too early.

This generated an estimate of original oil in place that was less than half of the known figure. In the example, that delta amounted to more than 1 million bbl of oil.

Outside of its impact on reserve estimates, one of the other potential ripple effects of such a miscalculation includes influencing an operator to make poor spacing decisions on the next project and to drill too many wells per section.

Carlsen said reservoir engineers would like to diagnose the ever-shifting profile of multiphase flow and its impact on production using analytical equations that they themselves can solve. However, “that’s literally impossible for a human to do,” he said, due to the multiplex of variables involved.

Enter numerical engines. The industry has been using this mathematical software tech for years to crunch big data sets—think seismic interpretation and reservoir simulation—and the joint project considers it a necessity in making RTA an everyday tool in unconventionals.

“We are saying everything that is extremely difficult for an engineer to do is delegated to a numerical engine which can very easily account for complex PVT, complex derivatives, multiphase flow effects, changing pressures and rates,” and so on, explained Carlsen. “We humans are then just doing the interpretations and running the numerical engines in a systematic manner.”

Embracing a Fractional Fracture System

Another chief finding of the joint project thus far speaks to why it is pushing for fractional RTA to become a sectorwide standard.

The 37-operator group demonstrated through proof of concepts and history matching that the method which was introduced into industry literature in 2020 is the best at identifying the three flow regimes: infinite-acting, transitional, and finally, boundary-dominated.

A better way to frame this might be to say that fractional RTA is considered essential in picking the middle regime—transitional flow.

Prior to this innovation, Carlsen stresses that the industry lacked a tool that could pull it off with a high degree of accuracy. In lieu of good models for transitional flow, he said some engineers have turned to “alternative physics” or the use of “fudge factors” to generate their solutions.

This is a big development since “most tight wells tend to have very long periods of transitional flow, meaning it’s the dominant flow regime of unconventional wells and especially the newer ones,” he added.

In simple terms, this part of the puzzle involves the coexistence of both infinite-acting flow along with boundary-dominated flow in the same well at the same moment in time.

As the name suggests, fractional RTA looks at the fracture network in fractals. This allows the model to consider that some fractures are flowing without having reached a boundary yet, while others have come into contact with another fracture’s zone of influence and are therefore boundary-dominated.

By representing both regimes at once, fractional RTA is considered to be offering a more realistic picture of tight wells since not all fractures are spaced evenly or will attain the same length.

As the standardization effort and knowledge sharing continues around these concepts, it may be too early to suggest that they are on the verge of sectorwide adoption. However, those helping fine tune the new RTA approaches collectively hold tens of thousands of wells with completion and production data stretching back years. It’s therefore conceivable that large unconventional programs in the not-too-distant future are poised to greatly benefit.

The RTA joint project is counting on this since many new wells yet to come will involve more complexities than prior vintages. This is particularly true in North America where most new wells are part of infill programs and in some cases “cube developments” that involve entire pads of brand‑new wells being completed in rapid succession.

Carlsen added that in today’s crowded well pads “you run the gamut of flowing boundaries” and that “there’s a high degree of interference between some of these wells which, if you don’t account for then your analysis is ruined.”

For Further Reading

URTeC 2429710 Analytical Pressure and Rate Transient Models for Analysis of Complex Fracture Networks in Tight Reservoirs by Jorge A. Acuña, Chevron.

URTeC 3724391 Fractional Dimension RTA in Unconventional Wells: Application in Multiphase Analysis, History Matching, Forecasting, and Interference Evaluation by Behnam Zanganeh, Chevron Canada Resources; Jorge A. Acuña, J Acuna Consulting.

URTeC 3718045 Multiphase Flowing Material Balance Without Relative Permeability Curves by Leslie Thompson and Barry Ruddick, Whitson AS.

URTeC 2967 Numerically Enhanced RTA Workflow–Improving Estimation of Both Linear Flow Parameter and Hydrocarbons in Place by Braden Bowie, Apache Corporation and James Ewert, IHS Markit.

URTeC 3718584 Numerical RTA Extended to Complex Fracture Systems: Part 1 by Mathias Carlsen and Curtis Whitson, Whitson AS.

SPE 210420 Numerical RTA Extended to Complex Fracture Systems: Part 2 by Mathias Carlsen and Curtis Whitson, Whitson AS.