Drilling automation

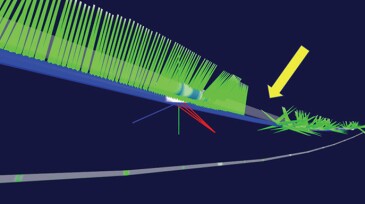

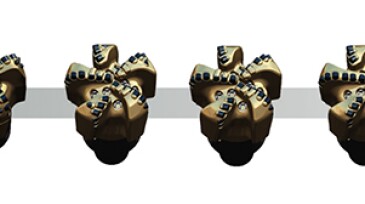

In this study, a method was developed to analyze the effects of drilling through transitions on bit-cutting structures and construct an ideal drilling strategy using a detailed drilling model.

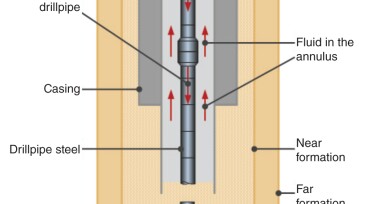

This paper describes a machine-learning approach to accurately flag abnormal pressure losses and identify their root causes.

This research aims to develop a fluid-advisory system that provides recommendations for optimal amounts of chemical additives needed to maintain desired fluid properties in various drilling-fluid systems.

-

Drilling automation champions met to identify where this emerging technology needs to be by the end of the decade. What they ended up agreeing on most was that the business models used today are largely incompatible with the technology of the future.

-

A pilot application using computer vision technology has been created to count and measure the pipe entering the wellbore and detect personnel movement in the red zone during pipe-delivery operations.

-

This paper discusses the results of driller stress tests and the implementation of a system that assists the operator in kick detection, space out, and preparation for well shut-in.

-

The authors describe a drilling-systems automation roadmap for a transition from humans to automation in the general drilling space.

-

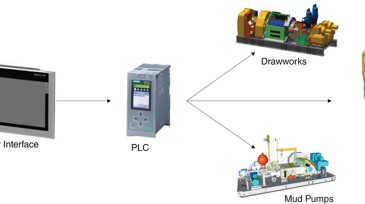

The authors describe a platform that integrates advanced data analytics and hydraulic modeling in real time for managed-pressure-drilling applications.

-

Totally automated drilling today looks like a robot doing all the heavy lifting on a drilling floor. By 2025, there may no longer be anything surprising about it.

-

A supervised machine-learning algorithm is developed to classify drilling parameters that increase rate of penetration and bit endurance for use in unconventional fields in Australia.

-

The failure of the Raptor rig to drill its first-ever well offers a short history of the challenges that came with creating the first automated drilling rig.

-

Drilling automation is not “there” yet, but it no longer seems like a pipe dream.

-

This paper describes how severe rig limitations were overcome through an optimization plan in which an optimal bottomhole assembly was designed and drilling practices were customized.