Drilling automation

In this study, a method was developed to analyze the effects of drilling through transitions on bit-cutting structures and construct an ideal drilling strategy using a detailed drilling model.

This paper describes a machine-learning approach to accurately flag abnormal pressure losses and identify their root causes.

This research aims to develop a fluid-advisory system that provides recommendations for optimal amounts of chemical additives needed to maintain desired fluid properties in various drilling-fluid systems.

-

The SPE Workshop “Impact of Digitalization on Drilling Operations” began on 29 November in Al-Khobar, Saudi Arabia, welcoming 316 attendees from 17 countries and 44 companies.

-

Nabors' RZR-equipped rig has successfully drilled multiple horizontal wells in the Permian Basin.

-

Remote operations and automation have reshaped the drilling landscape in recent years, but this may be just the beginning. Find out here which big milestones may be coming up next for the drilling sector.

-

This paper presents an automated directional-drilling process executed on a commercial well in the Norwegian sector of the North Sea, where a next-generation intelligent rotary steerable system completed a well section in a single run.

-

This paper describes a collaboration between the operator and a service company that resulted in a successful deployment of an automation platform to manage risks and optimize drilling operations in exploration wells.

-

This paper discusses the strategy, approach, and challenges faced in the adoption and implementation of an onsite and remote automated-drilling performance measurement.

-

An automated detection application helped identify stringers early for an operator of a mature field in the North Sea while drilling multilateral wells through reservoir sections containing hard calcite stringers interspersed in sand formations with low unconfined compressive strength. The application guided drilling decisions that minimized invisible lost time and sh…

-

Drillers are working to find ways to break some bad data habits. Those problems can range from the use of multiple formulas to calculate mechanical specific energy to timekeeping systems where the clocks and the time records are often off.

-

Industry experts from Fugro analyze what the future holds for offshore energy fields and how the industry can embrace and prepare itself for an autonomous and digital future.

-

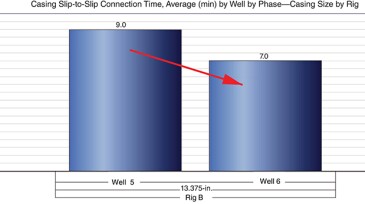

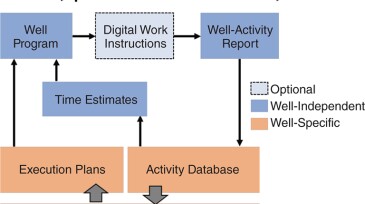

An operator has redefined onsite operations reporting through the development of a standardized set of reporting activity codes as the backbone of a standardized digital well-design and execution process.