Drilling automation

In this study, a method was developed to analyze the effects of drilling through transitions on bit-cutting structures and construct an ideal drilling strategy using a detailed drilling model.

This paper describes a machine-learning approach to accurately flag abnormal pressure losses and identify their root causes.

This research aims to develop a fluid-advisory system that provides recommendations for optimal amounts of chemical additives needed to maintain desired fluid properties in various drilling-fluid systems.

-

A real-time deep-learning model is proposed to classify the volume of cuttings from a shale shaker on an offshore drilling rig by analyzing the real-time monitoring video stream.

-

The best way to know how drilling affects drill bits is to visualize the bits. A device that creates high-resolution images for precise measurements is one of three technologies being featured in a JPT series on drilling measurement innovations.

-

A group of people who really care how drillers code the memos added to the daily drilling report is the data scientists—who find that the coded tags do not match the activity. A program that helps drillers code is one of three technologies featured in a JPT series on drilling measurement innovation.

-

ExxonMobil’s rig automation experiment is accelerating, with plans to push the number of rigs in the system from three to nine. Drilling efficiency was improved by use of an automated pipe-handling system, which reduced the median time required for connection at one location by 20%.

-

Engineering career tip of the day: If you are using Microsoft Excel at work, don’t leave it open on your computer when your boss is nearby.

-

Drilling rig automation is increasing as the industry realizes its benefits. What about downhole automation of the drilling process, specifically directional drilling? What problems might it solve and what opportunities might it create? The opportunity is huge, if only we look in the right place.

-

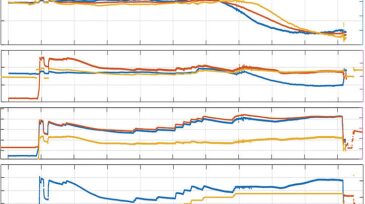

This paper shows how high-frequency, real-time drilling data from wired drillpipe has helped optimization of drilling performance and achievement of additional improvements in the New Mexico Delaware Basin.

-

This paper describes how new technology was implemented and deployed through a downhole acoustic network through a sequence of runs in complex North Sea wells under managed-pressure conditions.

-

This paper discusses how oil and gas companies are using a new generation of AI-driven applications powered by computational-knowledge graphs and AI algorithms to create a digital knowledge layer for oil and gas wells that provides a timeline of significant well events.

-

Hess is testing whether it can drive drilling improvement by combining drilling rigs equipped with automated functions and humans determined to find a way to beat the programmed drilling.