Drilling automation

In this study, a method was developed to analyze the effects of drilling through transitions on bit-cutting structures and construct an ideal drilling strategy using a detailed drilling model.

This paper describes a machine-learning approach to accurately flag abnormal pressure losses and identify their root causes.

This research aims to develop a fluid-advisory system that provides recommendations for optimal amounts of chemical additives needed to maintain desired fluid properties in various drilling-fluid systems.

-

Technology is advancing, and applications are growing, but scaling faces technological and human challenges.

-

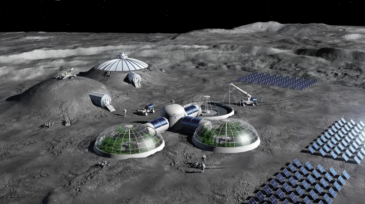

When humankind returns to the Moon to establish colonies it will be bringing with it technologies born in the oil and mining industries. The European Space Agency and Russia’s Roscosmos will be central to that effort as they prepare to land a robotic drilling system to extract oxygen and water from frozen lunar soil.

-

The authors describe challenges that must be overcome to reach the goal of drilling systems automation.

-

This paper details the introduction of a drilling automation system to deliver superior well-construction performance in a major gas field.

-

MPD was used to successfully drill through a pore pressure ramp and address a well-control event in conjunction with conventional methods.

-

Drilling automation and innovation continue as dominant trends despite market downturns and unprecedented challenges in the past year. In many ways, the drive toward new efficiencies and step changes in well-construction performance has taken on an even greater sense of urgency.

-

The complete paper presents a solution that integrates a physics-based torque-and-drag (T&D) stiff/soft string model with a real-time drilling analytics system using a custom-built extract, transform, and load translator and digital-transformation applications to automate the T&D modeling work flow.

-

The service companies plan to co-market an emerging well control system that can integrate with established managed-pressure-drilling components to enhance well construction safety and efficiency.

-

Brazil’s national oil company details the results of 6 years of real-time drilling monitoring. The next step is to move toward optimization, then automation.

-

An intelligent drilling optimization application performs as an adaptive autodriller. In the Marcellus Shale, ROP improved 61% and 39% and drilling performance, measured as hours on bottom, improved 25%.