Drilling/completion fluids

One major challenge for drilling-fluid engineers is the design and management of optimal drilling-fluid formulations in emerging frontiers—fractured formations and high-pressure geothermal environments. Recently, operators have leveraged cutting-edge technology such as machine learning and expanded data-driven techniques to facilitate the development of new drilling-f…

This research aims to develop a fluid-advisory system that provides recommendations for optimal amounts of chemical additives needed to maintain desired fluid properties in various drilling-fluid systems.

This paper describes development of a high-temperature water-based reservoir drill-in fluid using a novel synthetic polymer and customized with optimal chemical concentrations and sized calcium carbonate.

-

This year has been a great year for me; I was able to play more rounds of golf than expected! I was also successful in sealing a few research collaboration agreements within the oil and gas industry.

-

When oil-based mud is used, the drilled formation solids (cuttings) are regarded as controlled or hazardous waste.

-

A novel nonaqueous-fluid (NAF) system was designed to provide stable rheological properties with a nonprogressive gel structure and very good filtration control and filter-cake quality in wells where the expected bottomhole static temperature (BHST) exceeds 400°F.

-

A well in the South China Sea was diagnosed by ultrasonic and temperature logging to have a well-integrity problem, forcing the operator to shut in the well because the leak created a high tubing/casing-annulus pressure.

-

A novel solids-free fluid-loss pill for higher-temperature reservoirs has been formulated.

-

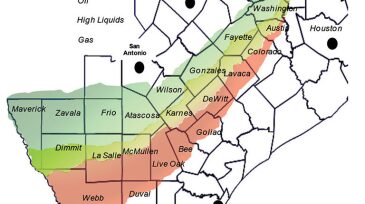

The Eagle Ford shale in Zavala County, Texas, is similar to many high-carbonate-content oil-shale formations.

Page 10 of 10