Drilling

An earlier deal to double Israel’s gas exports to Egypt led to approval of Leviathan’s Phase 1B expansion by guaranteeing long-term cash flow to finance the project.

Rystad Energy expects the continent to account for the largest share of frontier and basin-opening wells in 2026 as operators pursue scale and untapped resources.

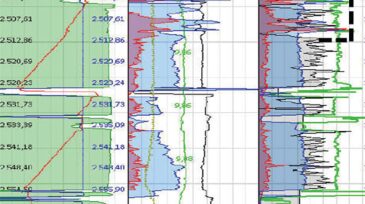

This paper presents a multifaceted approach leveraging precise rig control, physics models, and machine-learning techniques to deliver consistently high performance in a scalable manner for sliding.

-

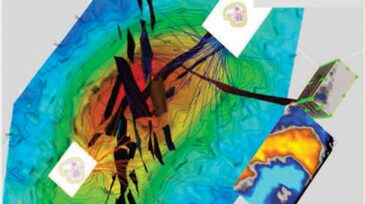

Advances during the past decade in using convolutional neural networks for visual recognition of discriminately different objects means that now object recognition can be achieved to a significant extent.

-

Our understanding of drilling with better software, instrumentation, machines, computer vision, downhole tools, and robots will continue improving the economics of horizontal wells, and the trend is set to continue. This is good news for the geothermal market.

-

This paper reports the effect of sodium dodecyl sulfate modified graphene (SDS-Gr) on the rheological features, fluid loss, and swelling inhibition mechanism of clay.

-

This paper describes a low-impact, nonaqueous drilling fluid (LIDF) designed to minimize equivalent circulating density (ECD) increases and associated risks in deep water by reducing the effect of cold temperature on fluid viscosity.

-

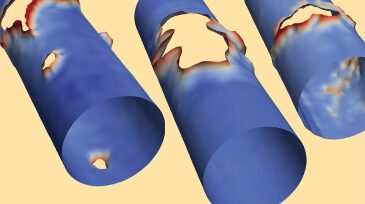

This paper discusses a new, comprehensive cuttings-transport model designed to enable safe and improved hole-cleaning operations.

-

The complete paper describes an offshore artificial island project northwest of Abu Dhabi in which drilling limits were extended continually by adopting new technologies and practices in an extended-reach-drilling (ERD) campaign.

-

The number of units that have been cold stacked since 2016 are in the double digits. Reactivation costs for these rigs range from $40 million to $100 million. Given current rates and contract durations, most of these are unlikely to return to work.

-

When a plug gets stuck in a well, consider the cause. Often stuck fracturing tools are a warning sign of casing trouble. Companies that have investigated plug problems have been surprised by the findings.

-

The complete paper provides an approach using machine-learning and sequence-mining algorithms for predicting and classifying the next operation based on textual descriptions.

-

Specifically targeting ingrained thinking, the selected papers demonstrate the game-changing results that can be achieved even when targeting long-established norms. They demonstrate everything that our industry should be proud of and what we strive for.