Drilling

The London-headquartered independent acquires position in the US Gulf while preparing Zama for final investment decision.

This study identifies critical knowledge gaps in wellbore integrity and underscores areas that require further investigation, providing insights into how wellbores must evolve to meet the technical demands of the energy transition.

This study illustrates the new capabilities, tailored for CO₂ storage applications, of a modeling framework that provides a quantitative, risk-based assessment of the long-term integrity of legacy plugged and abandoned wells.

-

CoreAll's Intelligent Coring System uses a suite of sensors to analyze reservoir cores samples as they are being acquired, and a communication system that sends these data to the rig in real-time.

-

Coring is essential to offshore exploration programs—but sometimes cores are taken from the wrong formation or return to surface in poor condition. One firm thinks it can solve these costly issues with a first-of-a-kind coring device that uses logging instruments that add accuracy and integrity.

-

The Bureau of Safety and Environmental Enforcement is proposing to update regulations covering offshore oil and gas drilling operations.

-

Stories from the IADC/SPE Drilling Conference look at how the next generation of engineers is performing, the hottest well ever drilled, and the art of translating drilling numbers into executive reports.

-

As leaders in digital drilling analysis push into real-time data analysis and digital controls, they are finally confronting data-quality problems. Humans are better than machines at dealing with ambiguous readings.

-

Sensor technology in the oil industry changes infrequently. Improvements in MEMS sensor technology are creating rapid momentum toward the use of tiny, rugged, and inexpensive sensors to replace larger, costlier, and more fragile legacy-technology sensors in directional drilling.

-

As the resources that the industry develops become increasingly challenging, access to a broader range of options and new and developing approaches allows more-efficient and -effective recovery.

-

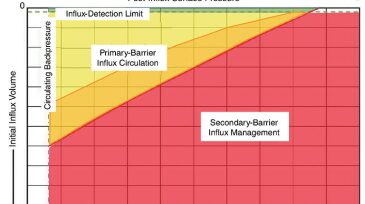

The influx-management-envelope (IME) concept is an advanced, innovative way to assess influx conditions in managed-pressure-drilling (MPD) operations, offering an improved tool for the decision-making process.

-

This paper discusses the successful design, laboratory testing, and performance of an innovative, low-solids, organophilic-clay-free invert-emulsion fluid (OCF-IEF) used to drill the reservoir section of an extended-reach-drilling (ERD) well.

-

Current long-reach technology already has a large effect on oil recovery. Many possible improvements, however, remain, and we see new contributions every year.