Drilling

Oil and gas companies drilled 75 “high-impact” wells in 2024, representing 5.2 billion BOE.

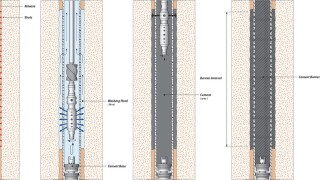

This paper presents a comprehensive literature review of perforate, wash, and cement techniques that compares new methods with traditional ones and uses field cases and computational fluid dynamics to find the most cost- and time-effective practices without sacrificing safety.

The authors of this paper describe a method of stimulating a multizone hydrocarbon-producing well wherein a tool is deployed downhole by wireline to generate acid vapor at a target depth, allowing each interval to be treated uniquely.

-

This paper discusses an expandable-liner-hanger (ELH) system that provides liner rotation during the liner deployment and the cementing operation while providing a hydraulically energized liner-top seal upon setting.

-

Despite cement’s remarkable properties, the search continues for enhancements in the areas of cost and isolation performance. Efficiencies and enhancements have been explored even to the point of replacing cement with other materials.

-

The conductor anchor node (CAN) technology was introduced as part of the architecture for Centrica’s Ivory deepwater exploration well in the Norwegian Sea to optimize efficient operations for the well’s riserless section.

-

Norway’s Statoil on 24 April played down concerns that drilling in the Arctic is risky, days before it starts its drilling campaign in the Barents Sea, where the country believes around half of its remaining resources could be located.

-

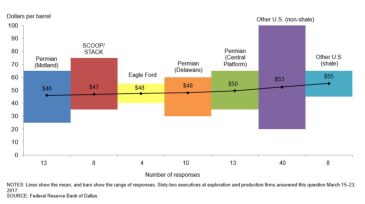

Aggressive drilling growth in the Permian and other shale plays belies the cost of those wells, which in many cases are in the red.

-

Deepwater operators continually face technical and environmental challenges to drilling and completing wells safely and efficiently.

-

This paper focuses on the application of radio-frequency-identification technology to enable an operator to eliminate an intervention run (or intermediate liner) for a 10,000-ft reservoir section.

-

One common issue among operators in determining whether to install a managed-pressure-drilling (MPD) system for a campaign is the significant upfront cost.

-

Pore-pressure prediction plays an important role in well planning as exploration targets shift to deeper, overpressured reservoirs.

-

The industry has developed a deep and healthy respect for systems-engineering processes and the associated full considerations during the deployment of new technologies. The result has been a significant improvement in the successful use and broader deployment of these attractive technologies.