Drilling

The London-headquartered independent acquires position in the US Gulf while preparing Zama for final investment decision.

This study identifies critical knowledge gaps in wellbore integrity and underscores areas that require further investigation, providing insights into how wellbores must evolve to meet the technical demands of the energy transition.

This study illustrates the new capabilities, tailored for CO₂ storage applications, of a modeling framework that provides a quantitative, risk-based assessment of the long-term integrity of legacy plugged and abandoned wells.

-

Researchers have developed a drilling-data-aggregation and -distribution system that seamlessly integrates all forms of data, file types, and communication protocols and incorporates human-factors engineering in the design.

-

Rockwell Automation’s Luis Gamboa explains his company’s new solution designed to allow operators to collect, sort, and reconcile the quality and quantity of data from multiple sources to optimize field data.

-

This new deal marks the second major acquisition of an offshore drilling company since the onset of the industry downturn.

-

While the slowdown offshore persists, this 96-year-old drilling outfit says that sharing its high-tech simulators with more of its clients will strengthen the business.

-

Wellbore-construction methods, especially casing-and-cementing practices for the protection of freshwater aquifers, have been reviewed in the Piceance, Raton, and San Juan Basins in Colorado.

-

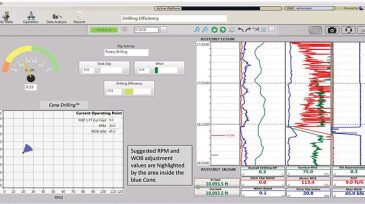

Software that offers turn-by-turn directions for drilling a horizontal well could drastically reduce the number of directional drillers.

-

Drilling activity in US shale plays is slowing as operators encounter higher prices for labor, equipment, and services, and lower prices for the oil and gas produced.

-

A new attachment system overcomes the limitations of traditional methods for securing tools and accessories to drilling and completion strings.

-

An analyst from Rystad looks at the state of the offshore drilling market and the likelihood of recovery by 2021.

-

Advanced horizontal drilling, multistage hydraulic fracturing, and other technologies have helped make the Vaca Muerta shale oil and gas resource economically viable.