Drilling

Oil and gas companies drilled 75 “high-impact” wells in 2024, representing 5.2 billion BOE.

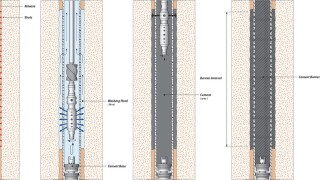

This paper presents a comprehensive literature review of perforate, wash, and cement techniques that compares new methods with traditional ones and uses field cases and computational fluid dynamics to find the most cost- and time-effective practices without sacrificing safety.

The authors of this paper describe a method of stimulating a multizone hydrocarbon-producing well wherein a tool is deployed downhole by wireline to generate acid vapor at a target depth, allowing each interval to be treated uniquely.

-

At certain conditions, the good performance of synthetic-based mud (SBM) will degrade, particularly because of the effect of chemical instability under high temperature. Silicon dioxide (SiO2) nanopowder (nanosilica) holds the potential for performance improvement.

-

Experience has revealed that frictional pressure loss in the wellbore hinders the full use of the entire length of the horizontal well. This paper presents a new approach to maximize the use of the full length of long horizontal drainholes.

-

This study compares the performance of openhole-packer completion systems with that of cemented-liner completion systems in the northern Montney gas resource play.

-

In horizontal and extended-reach wells in which long completions are run into highly deviated or lateral zones, large compression loads arise because of running friction.

-

The engineering and operational planning to ensure that no uncontrolled hydrocarbon releases occur during the execution of subsea big-bore gas wells are described.

-

Understanding drilling dynamics, the downhole shock and vibration that occur while drilling, is a crucial step to improving drilling efficiency and reducing nonproductive time (NPT).

-

With limited resources and lots of dedication, West Virginia University students wowed judges of the ATCE Drillbotics drilling automation challenge with the automated drilling device they built.

-

In organic shales, hydraulic fracturing is important for optimizing the production of horizontal wells. For a standalone lateral, the propped surface should be maximized to increase production. In the case of a pad, well spacing is an additional factor.

-

This paper offers an alternative explanation for the early boundary-dominated flow related to dissolution of salt-sealed natural fractures in the shale.

-

A Drilling Advisory System (DAS) is a rig-based drilling-surveillance and -optimization platform that encourages regular drilloff tests, carefully monitors drilling performance, and provides recommendations for controllable drilling parameters to help improve the overall drilling process.