Drilling

Oil and gas companies drilled 75 “high-impact” wells in 2024, representing 5.2 billion BOE.

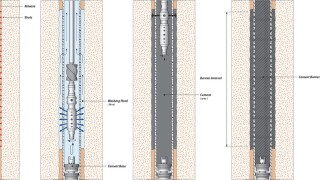

This paper presents a comprehensive literature review of perforate, wash, and cement techniques that compares new methods with traditional ones and uses field cases and computational fluid dynamics to find the most cost- and time-effective practices without sacrificing safety.

The authors of this paper describe a method of stimulating a multizone hydrocarbon-producing well wherein a tool is deployed downhole by wireline to generate acid vapor at a target depth, allowing each interval to be treated uniquely.

-

Wireline continuous coring (WCC) has been adapted from the mining industry for unconventional resources. This paper is aimed at identifying and addressing complications experienced in the use of WCC.

-

Precise casing-wear prediction is important for improving well integrity and longevity, while simultaneously making casing designs more cost-effective. There are no industry guidelines for casing-wear prediction. This article presents a validated predictive model.

-

A number of companies are pushing for alternative approaches to offshore development that seek to access marginal reservoirs. Their differing and unique ideas call for a departure from the usual playbook, but share a common goal of slashing capital costs.

-

This paper analyzes differing well-factory approaches to unconventional assets, with examples from the Wolfcamp unconventional oil play in the Permian Basin.

-

Anyone selling something new for offshore exploration and production has to be able to answer a simple question from customers, “How can we save some money?” For Norwegian oil companies, change is coming in many forms: steel, sensors, software, and standards.

-

Baker Hughes is developing a drill bit capable of auto-adjusting its depth-of-cut feature to handle dynamic drilling conditions.

-

A real-time method is presented to predict impending stuck pipe with sufficient warning to prevent it. The new method uses automated analysis of real-time modeling coupled with real-time-data analysis.

-

Challenging environments such as unstable clay formations represent high operational risk when running tubulars after drilling is completed.

-

Larger-diameter coiled tubing recently has been used to perform millouts because of its improved set-down force and increased annular velocities for cleanout purposes. Service companies and operators have reduced the number of wiper trips when using larger-diameter CT, to save time and money.

-

This paper describes experiences, challenges, and approaches to solving the problems related to creating an advanced early kick-detection system suitable for floating mobile offshore drilling units.