Drilling

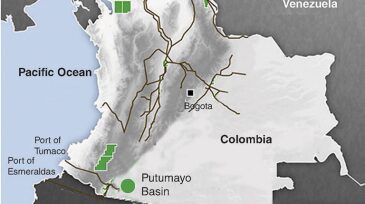

The London-headquartered independent acquires position in the US Gulf while preparing Zama for final investment decision.

This study identifies critical knowledge gaps in wellbore integrity and underscores areas that require further investigation, providing insights into how wellbores must evolve to meet the technical demands of the energy transition.

This study illustrates the new capabilities, tailored for CO₂ storage applications, of a modeling framework that provides a quantitative, risk-based assessment of the long-term integrity of legacy plugged and abandoned wells.

-

Sustaining innovation and well performance during economic downcycles is a hot topic right now. However, the severity of this downturn has resulted in an unprecedented purging of existing paradigms. In this context, it is important to reveal and highlight new initiatives and success stories.

-

This paper describes the method developed to achieve underbalanced drillstem testing (DST) in a deepwater field offshore India.

-

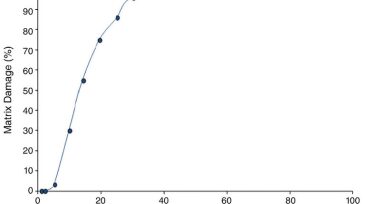

Understanding of formation damage is a key theme in a waterflood project. An integrated multidisciplinary approach is required to determine an optimal design and strategy.

-

The paper describes a novel methodology to construct distributed formation damage across openhole wells in carbonate reservoirs and to evaluate the effects of damage on zonal productivity.

-

This paper summarizes a wide variety of sandstone-acid-stimulation case histories, highlighting aspects such as mechanical conditions and operational practices.

-

When the industry discusses subsea wells, the tophole construction gets scant attention. The Norwegian company NeoDrill believes it can create a more structurally stable foundation, greater efficiency, and reduced cost by using a conductor anchor node.

-

US drilling and completion companies that were slashing workforces and cannibalizing pumping trucks for parts 6 months ago are now hiring crews and repairing equipment to meet rising demand.

-

Drilling automation is one of the most promising emerging technologies that the oil and gas industry has to look forward to. The potential benefits span the spectrum from health and safety to lower costs and repeatable well results.

-

This paper describes the first job in southeast Asia in developing horizontal-well placement in a turbidite environment.

-

The successes and challenges of producers in the United States’ most active oil play received a wide-ranging discussion by three panelists recently at an SPE Gulf Coast Section meeting in Houston on the state of the Permian Basin.