Inspection/maintenance

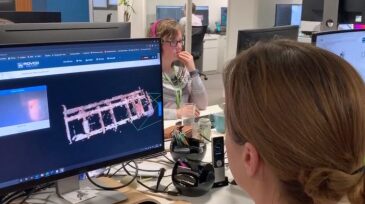

The Norwegian major said it is using artificial intelligence for predictive maintenance throughout its facilities and for interpretation of seismic data from the Norwegian continental shelf.

Sponsored

As HPHT wells push equipment to the edge of material limits, operators are turning to advanced thermoplastics and sealed electrical assemblies to maintain system integrity. From ESP insulation to BOP control systems, the right component design can prevent failures, lower intervention costs, and extend equipment life in the harshest offshore environments.

This paper presents an approach to management and interpretation of pipeline-integrity data, ensuring integrity, safety, and reliability of the operator’s critical pipelines.

-

The data-driven maintenance program incorporates riser condition, usage, and fatigue analysis with a risk-based inspection process.

-

As companies look to reduce the time it takes to inspect a subsea pipeline, as well as the costs involved in the operation, autonomous systems have become a more desirable option. How close are they to becoming the norm?

-

Rovco’s stereo camera technology system sends images and 3D models of assets from the seabed to computer browsers in any location, offering users instantaneous access to information during inspection or construction.

-

A proving ground for the use of digital twins has emerged in the North Sea. There, operators Total, Aker BP, and Shell have each developed and deployed twins that they expect to pay big dividends.

-

ADNOC will utilize Honeywell’s asset monitoring and predictive analytics platform to improve asset efficiency and integrity across the operator’s upstream and downstream businesses.

-

Equinor has chosen four suppliers for inspection services on all offshore installations on the Norwegian Continental Shelf and onshore plants in Norway. The frame agreements, estimated at $383 million, are scheduled to be signed soon.

-

Sensors, robots, and artificial intelligence have made their way into a number of areas within the industry, including pipeline inspections. Shell has begun to examine the innovative technologies that could shift the inspection paradigm.

-

The company used a maintenance optimization plan from Lloyd's Register for the centrifugal pumps and fire and gas detectors on a floating production, storage, and offloading vessel in the Norwegian Sea.

-

Risk-based inspection is based on sophisticated risk analysis which significantly decreases overheads and helps to avoid equipment failures or unnecessary shutdowns.

-

The $43-million deal with Saipem will utilize a wireless underwater intervention drone and an ROV for intervention work on the Njord field in the Norwegian North Sea. Equinor said the contract is the first ever from an operator for advanced wireless drone services.