Inspection/maintenance

The Norwegian major said it is using artificial intelligence for predictive maintenance throughout its facilities and for interpretation of seismic data from the Norwegian continental shelf.

Sponsored

As HPHT wells push equipment to the edge of material limits, operators are turning to advanced thermoplastics and sealed electrical assemblies to maintain system integrity. From ESP insulation to BOP control systems, the right component design can prevent failures, lower intervention costs, and extend equipment life in the harshest offshore environments.

This paper presents an approach to management and interpretation of pipeline-integrity data, ensuring integrity, safety, and reliability of the operator’s critical pipelines.

-

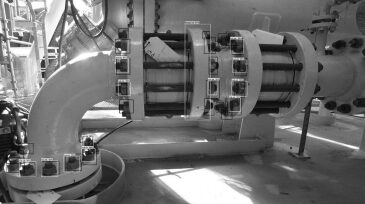

Using machine learning (ML), image recognition, and object detection, the use of ML on algorithms to recognize objects and describe their condition were investigated—offering new possibilities for performing inspection and data gathering to evaluate the technical condition of oil and gas assets.

-

As part of an effort to evaluate existing riser systems, an operator launched an inspection and testing program to investigate risers retrieved following well abandonment after a service life of nearly 10 years in the Gulf of Mexico.

-

Thermal imaging helps operators maintain regulatory compliance on methane-emissions requirements. Optical gas imaging technology may be an answer in allowing for faster, more efficient inspections, but there are hurdles to its adoption. How can its widespread use become a reality?

-

Analytics, sensors, and robots are changing the way one of the world’s largest oil and gas companies does business. Underpinning all the new technology though is a shift in how BP thinks, and what it means to be a supermajor in the 21st century.

-

During the last decade, the use of drones for industrial asset inspections has grown significantly. The ability to inspect in-service flares can eliminate millions of dollars of operational expenditure and mitigate safety risks presented by traditional access methods.

-

This digital deal is helping to make augmented reality a new reality for oil and gas operations.

-

Called Eelume, the underwater drone will perform subsea inspection, maintenance, and repair work.

-

The need to optimize tank turnaround schedules is as great as it has ever been within the midstream sector, but traditional human-based tank inspections often cut into uptime while introducing safety risks. New robotic applications aim to alleviate these issues.

-

As we move to digitize our visual inspections with a variety of image-capture devices, fully understanding the strengths and limitations of the approach is important to move truly from a qualitative to a quantitative assessment with confidence.

-

Subsea inspection/repair/maintenance services have traditionally relied on vessel-based, ROV, or diver operations. In the longer term, identifying significant incremental savings in these operations is not sustainable and an innovative approach deploying digital technologies is being investigated.