In the subsea environment, inspection/repair/maintenance (IRM) services have traditionally relied on vessel-based, ROV, or diver operations. In the longer term, the drive to continually identify significant incremental savings in these operations is not sustainable and a more innovative approach, deploying digital technologies, is being investigated.

With the aim of significantly reducing OPEX costs as well as minimizing environmental impact, industry leaders are embracing the future value of autonomous subsea vehicles. These underwater drones can potentially be the resident eyes and ears on the seabed, reducing the need for a field support vessel to oversee all IRM activities.

A Blueprint for Autonomous Subsea Vehicles

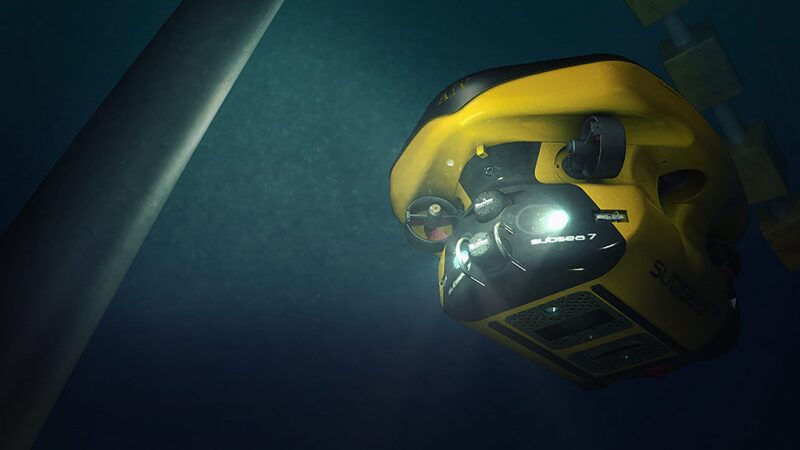

For more than 2 decades, i-Tech Services (a Subsea 7 company) has been actively developing its autonomous subsea inspection vehicle capability to support and maintain the integrity of subsea production assets. The current system, the Autonomous Inspection Vehicle (AIV), is essentially a hovering vehicle, much like an ROV without a tether, which can stop, carry out its inspection task, and then travel to and autonomously dock into a recovery basket.

Equinor Pilot Study

Based on its track record in supplying ROV and intervention services and knowledge of autonomy in subsea vehicles, Equinor engaged the company in 2017 to investigate a new method of providing fieldwide IRM services.

Named the Underwater Intervention Drone (UID), the pilot study investigated and reported on its use for the Snorre Expansion Project (SEP) and Snorre A (SNA) field, located in the Tampen area of the North Sea. It also considered its use for other fields. The field layouts of SNA and SEP were selected because of its three pipeline production bundles, which can support hosting of the vehicle systems on the seabed. The EPCI contract for three bundles was awarded to Subsea 7 last year with offshore operations taking place in 2019 and 2020. Dedicated power and fiber-optic cables fitted into the pipeline bundle have been sanctioned at seven locations.

For long-term deployment, protective docking stations are to be strategically positioned on the seabed. Towhead connectors will provide power and communications to the subsea docking station and a central onshore control center (OCC) will manage and control the tasks allocated to the vehicles. This network will provide communication connectivity between the OCC and docking stations and the SNA platform for power.

Over the 6-month investigation, the study assessed the potential for introducing subsea hybrid vehicles by identifying any technical gaps that would prevent the long-term deployment of the UID on the seabed. It also evaluated and recommended options for docking station configurations to support the vehicle by providing overview of the configurations and characteristics required. As power and a reliable data network are integral to its success, the company examined operational and management provisions to support activity by the subsea hybrid vehicle. The ultimate aim of the project was to recommend a development plan to enable the drones to go “live” by late-2020.

While the study concluded that there were no technical showstoppers for an autonomous underwater vehicle to be ready for deployment within 2 years, it did assert that elements of its development and transformation of existing infrastructure would need to be accelerated to deliver a viable and reliable service within the tight timeline. This recommended addressing the following issues:

Power distribution

The power available at the docking station is limited by the power available at the Snorre A platform, component rating, and the transmission distance to the subsea docking stations. Careful management of the power distribution is required to ensure that the maximum amount of power is available to the vehicle or docking station that has operational priority. An intelligent rule-based power management system maintains service utilization suitable for the field operational tempo.

Communications infrastructure

Careful management of network traffic is required to ensure reliability and security of the communications link.

For example, when the hybrid vehicle is resident in a docking station, high-bandwidth communications between it and the OCC are achieved using the bundle network and SNA to onshore communications links.

In ROV mode with real-time human-in-the-loop control, communications are extended from the docking station to the deployed vehicle. This can be achieved by using an umbilical tether, though this introduces a risk of entanglement, or a high-bandwidth telemetry link through water, which itself has challenges in coverage and range. Optical technology is currently considered the most applicable to move large volumes of data in real time.

Docking station

Several options for the configuration and location of the docking stations are possible, depending on the type of vehicle and economics around the installation and lifetime servicing of the dock. For instance, they can be built into the pipeline bundle or be a standalone structure tied back into the connection points on the bundle.

In all cases, the main foundations of the dock, which will consist of structural elements only, are expected to be in place for the lifetime of the field and will not be serviceable items. Therefore, a replaceable power and communications interface should be fitted to the foundation structure to support recharging and links with the vehicle. While the docking station interface (DSI) should not require routine maintenance, a changeout will be possible in the event of failure or upgrade.

To provide protection and direct interfaces to the vehicle, the main components will be enclosed in the docking station where routine recovery is possible for servicing caused by wear and tear.

Network management

Various personnel will use the DSI system both simultaneously and independently. Certainly, the operator of the DSI infrastructure will need to control and monitor the infrastructure for general housekeeping checks and control of the power distribution at DSI stations, for example.

As the backbone of efficient, real-time communications, it is paramount to ensure that the OCC networks are aligned to provide seamless tunnelling of data and to encapsulate standard LAN network interfaces between the OCC, the DSIs, and the vehicles.

While these developments, changes, and adaptations are not insurmountable, they do require careful engineering to ensure the configurations comply with requirements and meet the goal of reducing OPEX costs and CO2 emissions.

Differing Demands

A subsea hybrid vehicle should be capable of both autonomous flight and real-time human-in-the-loop control. However, this is currently not met by a single vehicle on the market. As such, this requires a new type of vehicle that fuses both capabilities as well as addressing differing vehicle requirements depending on its location on the seabed.

For instance, around the platform, it would be expected to perform cleaning, dredging, component changeout, as well as autonomous general inspection and observation tasks. This requires high levels of power over significant timescales. Currently a system that has the characteristics of the more conventional work ROV with access to high levels of power through a dedicated umbilical seems more suited than one configured for the in-field area.

The features of the platform area that drive this are:

- Dynamic risers and mooring chains

- Complex sea current interactions around the mid-water structures

- Strong sea currents at shallower depths (<50 m)

- Hard and dense marine growth in shallow depths (<50 m)

For the in-field area, the vehicle will typically carry out inspection and light intervention tasks in and around the templates, where it will have constant communications with the OCC. It will have the ability to autonomously navigate across the field to relocate to each template or conduct inspection of the interconnecting pipeline bundle. For more complex operations, a pilot can supervise the vehicle in real time. On completion of its duties, the vehicle will return to the docking station for recharging. The development of this hybrid vehicle will encompass existing ROV technology with autonomous capability.

Essentially, the hybrid system must typically balance the requirements of hydrodynamic efficiency, available power, and intervention capability. Working example of vehicles on the market today that have the required characteristics are the i-Tech Services AIV and the SAAB Seaeye Sabretooth.

The i-Tech Services AIV is a hovering, autonomous and intelligent inspection vehicle that can be deployed from a host platform, FLNG, FPSO, vessels of convenience, or ROVSVs (remotely operated vehicle support vessels) within the field. It carries the latest sonars and cameras for general visual inspection of facilities, pipelines, and risers within offshore fields and can be deployed in depths up to 3000 m.

The AIV technology is an enabler for a full-seabed-hosted option. The extensive knowledge of i-Tech in developing and operating the AIV technology was used as the basis of the pilot study with Equinor.

An Autonomous Future

The oil and gas industry has already seen huge strides in the understanding and acceptance of robotic equipment to perform tasks; the addition of autonomy and intelligent behavior is the natural evolution and has the potential to transform operations across the sector.

Equinor is now utilizing findings from the study with the aim of sanctioning the UID as a permanently available subsea inspection and light intervention capability at all production locations in the Snorre field. By reducing the need for field support vessels, autonomous systems can provide a step change in the way that IRM work is carried out in the future.

A pilot study of this kind shows that the industry is taking such innovation seriously. For a sector considered conservative in its approach, this is a major step forward in its quest to deliver sustainable and profitable subsea operations.

Reference

OTC 28766-MS (2018)

As a Chartered Electronics Engineer, Jamieson has spent more than 30 years working with underwater vehicles and robotics in design, development, and operations. He is part of the “Life of Field” team in Subsea7 and has held several roles in engineering, project management, and technology development.