Reservoir simulation

The aim of this study is to incorporate detailed geological, petrophysical, and hydraulic fracturing models to better predict and mitigate the effects of interbench interactions.

The objective of this paper is to apply a developed workflow to determine the propped hydraulic fracture geometry in a horizontal multistage fractured well, incorporating production, pressure, and strain data.

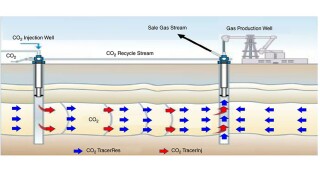

This study explores the feasibility of implementing in-situ carbon dioxide recycling for sequestration as a fit-for-purpose developmental strategy for a Malaysian gas field characterized by an initial carbon-dioxide content of approximately 60%.

-

Looking back through previous editions of this article, I note that, in 2011, I wrote, “there’s a growing tendency in some quarters to use very simple models.” That may be true, but there is also a growing tendency among vendors to offer models with more and more features.

-

Large volumes of gas can be produced at high rates with conventional horizontal- or vertical-well configurations for long periods of time from some methane-hydrate accumulations by means of depressurization-induced dissociation.

-

Initializing a reservoir simulator requires populating a 3D dynamic-grid-cell model with subsurface data and fit-for-purpose interrelational algorithms. In practice, these prerequisites rarely are satisfied fully.

-

This paper describes an all-in-one system that combines nodal-analysis and numerical-simulation models to calculate the effect of intelligent-completion components—such as swell packers, internal control valves, and inflow-control devices—on lateral production profiles.

-

The Kitan oil field consists of three subsea intelligent wells. The intelligent completions were modeled in detail using commercial dynamic-simulation software to establish a sound and safe operating procedure for the well cleanup and well test.

Page 17 of 17