Offshore/subsea systems

The company has installed an autonomous drone system on Aker BP’s Edvard Grieg platform in the North Sea, enabling frequent, remote inspections from shore.

Updates about global exploration and production activities and developments.

Once labeled “undrillable,” Brazil’s heavy-oil Atlanta field in the Santos Basin faced technical, financial, and logistical challenges. But through a phased approach, clever reuse of assets, and disciplined project execution, Brava Energia transformed a risky deepwater asset into a producing field with 172 million BOE in 2P reserves.

-

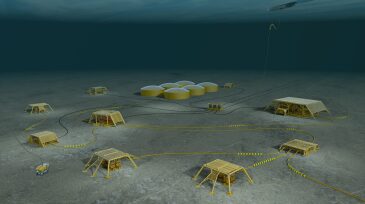

Both operational experience and studies of future offshore gas-field developments are showing that subsea gas-compression systems not only reduce investment costs but also increase recovery significantly.

-

In 2015, the world’s first subsea multiphase gas compression system was installed offshore Norway. The system comprises two-off 5-MW machines configurable for serial or parallel compression. This system has now gained considerable and valuable operational experience.

-

Armada to install ROV launch and recovery system on its fleet of robotic ships.

-

A new idea from Equinor calls for autonomous submarines to transport CO2 from the surface to the seabed. The Norwegian operator says the shuttles could also carry oil and water for injection.

-

WFS Technologies’ collaboration is its second in as many months supporting its Seatooth technologies.

-

While a year with less than 200 subsea tree awards seems uncommon, a year with less than 100 awards is an even rarer sight. It has only happened once before since the turn of the century, in 2016 following the oil price crash of 2014–2016.

-

The W-Industries contract comes 2 months after Worley was awarded a master service agreement for services on the Mozambique LNG project.

-

Proposal requests were sent to companies to solicit partnerships for the project with ADNOC and ADPower.

-

The A-frame is DNV certified. TechnipFMC’s ROVs will deploy in GoM later this year.

-

The complete paper presents a practical approach for validating design-verification analysis for subsea equipment, using a representative pressure valve block to correlate finite-element analysis (FEA) predictions for strain changes with actual measured changes.