Offshore/subsea systems

The awards build on Tenaris’ role in earlier phases of the ultradeepwater Black Sea project.

An earlier deal to double Israel’s gas exports to Egypt led to approval of Leviathan’s Phase 1B expansion by guaranteeing long-term cash flow to finance the project.

Marking a major milestone as the Gulf of Mexico’s second 20,000-psi deepwater development, the project underscores how advanced high-pressure technology, management of flow challenges, and the floating production system’s role as a regional hub are helping open the door to more Inboard Wilcox development.

-

The complete paper highlights elements of the technical development and an overview of the primary building blocks of the system, and presents in detail some of the challenges in developing, designing, and testing the control system.

-

Subsea completions for gathering hydrocarbons from subsea wells have demonstrated both environmental and economic benefits for offshore oil and gas projects. Barriers and opportunities for expanded use of subsea completions involve both technological and regulatory issues.

-

The Neptune-operated project is on track to start drilling later this year, with first oil scheduled for the end of 2020. The Norwegian North Sea field is expected to produce 30,000 BOE/D at its peak.

-

Completion comes despite two cyclones disrupting the project area during installation, McDermott said.

-

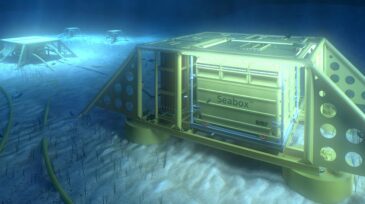

Operators are looking for ways to better handle water coming from subsea wells, which is typically treated at topside facilities. Subsea separation systems are not equipped to discharge water back into the reservoir, so how do companies close the gaps?

-

Ashtead Technology has acquired Louisiana-based subsea equipment rental and cutting services specialist, Aqua-Tech Solutions, as part of the company’s international growth plans in the US.

-

Cutting-edge computing and subsea wireless camera technology deployed on a pipeline construction project enhanced diver safety and generated significant cost savings by avoiding the need for additional subsea vessels.

-

Aker Solutions and FSubsea have agreed to a joint venture, named FASTSubsea, to help operators increase oil recovery.

-

From its record high in 2014, purchases of subsea equipment and SURF fell around 50% until reaching a low in 2018. New data suggest that the subsea market will be a top-performing oilfield service segment.

-

The past year ended with a surge of subsea tree awards as E&P operators locked in lower supply-chain cost. Will demand continue to grow in 2019 and allow subsea OEMs to build backlogs and take back pricing power?