Offshore/subsea systems

The awards build on Tenaris’ role in earlier phases of the ultradeepwater Black Sea project.

An earlier deal to double Israel’s gas exports to Egypt led to approval of Leviathan’s Phase 1B expansion by guaranteeing long-term cash flow to finance the project.

Marking a major milestone as the Gulf of Mexico’s second 20,000-psi deepwater development, the project underscores how advanced high-pressure technology, management of flow challenges, and the floating production system’s role as a regional hub are helping open the door to more Inboard Wilcox development.

-

Innovations characterize the deepwater Moho Nord field development, recently brought on stream by Total in the Republic of Congo, and the project creates significant value for the country.

-

Results of the experimental and numerical heat-transfer analysis conducted on a T-shaped acrylic-glass pipe, representing a production header in a subsea production system with a vertical deadleg.

-

A real-time production-surveillance and -optimization system has been developed to integrate available surveillance data with the objective of driving routine production optimization.

-

A new tool enables variable bore rams and shear rams to be tested in one run, cutting rig time significantly.

-

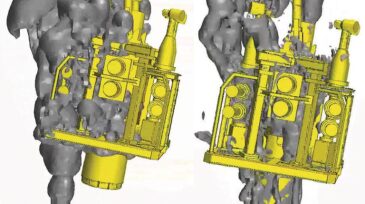

Developing a well-specific subsea-capping contingency plan involves assessing the feasibility of deploying a capping stack from a floating vessel, determining the weight and stability, and performing dynamic-flow simulations of closing the capping stack outlets.

-

Subsea tieback of a new field to an existing offshore production facility is one option to minimize development costs.

-

This paper presents the development of Sapinhoá field, covering the fast-track transition and decision-making process, from appraisal to conceptual and basic engineering of the Sapinhoá pilot project and on to its subsequent execution, highlighting the challenges, lessons learned, and results.

-

Subsea processing is an evolving technology in ultradeepwater development and has the potential to unlock a significant amount of hydrocarbon resources. In this paper, the authors have reviewed the application of subsea systems in 12 deepwater fields and discussed the significance of each.

-

Successful rejuvenation of two declining fields was enabled through innovation in both engineering and procurement strategy.

-

The deepwater industry uses technology qualification (TQ) as a tool to determine which safety barriers are needed, and what level of testing is required. Even without failure data from the field, a method has been developed to quantify the integrity of various components.