Floating production systems

Marking a major milestone as the Gulf of Mexico’s second 20,000-psi deepwater development, the project underscores how advanced high-pressure technology, management of flow challenges, and the floating production system’s role as a regional hub are helping open the door to more Inboard Wilcox development.

Despite a 2.8% drop in liquefied natural gas exports in 2025 because of lost market share in China, Australia anticipates a 2026 rebound as new North West Shelf capacity comes online. Meanwhile, East Coast operators brace for a tsunami of wells entering the decommissioning pipeline and potential energy shortfalls necessitating LNG imports.

Woodside’s $12-billion gas project offshore Western Australia is expected to produce up to 8 mtpa once it’s complete.

-

For Anadarko, the secret of the “design one, build many” approach to offshore production facilities is to control its enthusiasm for change. The company’s experience with eight operated spars shows the benefits gained with this approach.

-

A new type of organically modified silica glass that can remove a wide variety of oils and contaminants from produced and flowback water is showing promising results as it undergoes field trials.

-

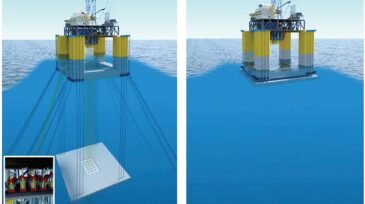

Semisubmersible floating production systems (SFPSs) with steel catenary risers (SCRs) are attractive field-development solutions, especially in deeper water of Western Australia. However, SCR design is challenging in the offshore Western Australia environment because of severe cyclonic environments.

-

Although the commissioning of a floating production system (FPS) generally takes place between the “mechanical completion” and “first oil” stages, commissioning activities begin long before then.

-

LLOG Exploration’s Delta House floating production system (FPS) looms large over Kiewit Offshore Services’ fabrication yard in Ingleside, Texas.

-

After severe damage in a typhoon, the Huizhou oil field in the South China Sea was back on production in 5.5 months. This paper reviews how this feat was accomplished.

-

The SPE Gulf Coast Section’s Project, Facilities, and Construction study group is hosting a series of lectures, “What Have We Learned About Host Selection in Deepwater GOM After 20 Years of Being Off the Shelf?

-

The market for floating production systems is growing rapidly, with spending from 2014-2018 expected to increase more than 100% from the prior 5-year period. Factors such as increased local content contribute to growing expenditures.

-

Roughly one-half of global gas reserves are considered stranded gas--uneconomical because of the remote location of potential markets, lack of economic transportation and infrastructure, or the lack of conversion technology. An FPSO with gas to liquids conversion is an option for stranded gas.

-

Good early production caused an FPSO to reach the design topside limit with only five wells connected. A study was undertaken to determine how bottlenecks could be reduced to allow greater production without compromising process safety.