Water management

This paper describes a decision-support system that integrates field data, system specifications, and simulation tools to quantify system performance, forecast operational challenges, and evaluate the effect of system modifications in water management.

This paper demonstrates that high-purity salts of calcium, magnesium, strontium, sodium, and lithium can be recovered from produced-water brine using a chemical-reaction pathway followed by vacuum-driven crystallization and a lithium-extraction process.

The authors of this paper aim to design, optimize, and evaluate a scalable and energy-efficient plasma-driven advanced-oxidative-process system for produced-water remediation, emphasizing regulatory compliance for safe discharge or reuse.

-

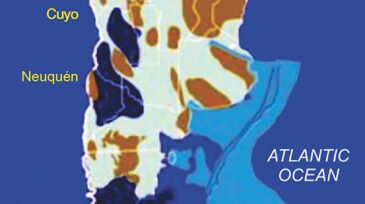

This paper discusses aspects of water logistics necessary during the well-completion phase, fracture-treatment designs applied in Vaca Muerta, and laboratory studies performed on flowback and produced water to help evaluate the potential for water reuse.

-

A surge in earthquakes tightly clustered in southern Kansas that followed the large increase in produced water injections prompted the state to cut the daily limits on disposal wells in that area to see if that will help solve the problem.

-

In the current economic environment, efficient water management practices will become even more essential for companies looking to run successful hydraulic fracturing operations.

-

The SPE Trinidad and Tobago Section recently hosted an Applied Technology Workshop (ATW) on oil and gas effluent discharge management that brought together those responsible for generating effluent discharges, regulators, and those creating treatment technologies

-

There is no denying that the oil and gas industry, as well as the agencies that regulate its activities, have significantly improved many aspects of environmental performance. Despite this progress, there is always more to be done to identify and manage risks associated with oil and gas development.

-

Produced water from chemical floods can cause problems for separation and water treatment equipment due to the polymers and surfactants used. Challenges are greater offshore where space limitations can affect treatment options.

-

Operators are increasingly sampling local groundwater prior to drilling as a risk management approach to deal with public concerns about hydraulic fracturing and other activities.

-

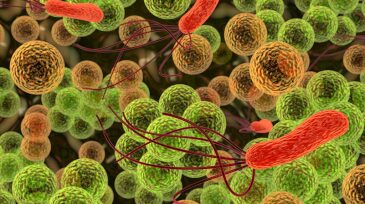

Though a best practice for sustainable hydraulic fracturing operations, using nonpotable water creates an environment in which microorganisms thrive. If left unchecked, bacteria can affect the environment and the economic viability of the hydraulic fracturing operation.

-

Water treatment systems in the North Sea differ from those in the deepwater Gulf of Mexico (GOM). This paper provides a detailed understanding of these differences and provides insight into the design of water-treatment systems in general.

-

Many oil and gas companies are pursuing fracture-flowback-water and produced-water recycling for subsequent drilling and fracturing operations. Removal of metals is important to success of these processes.