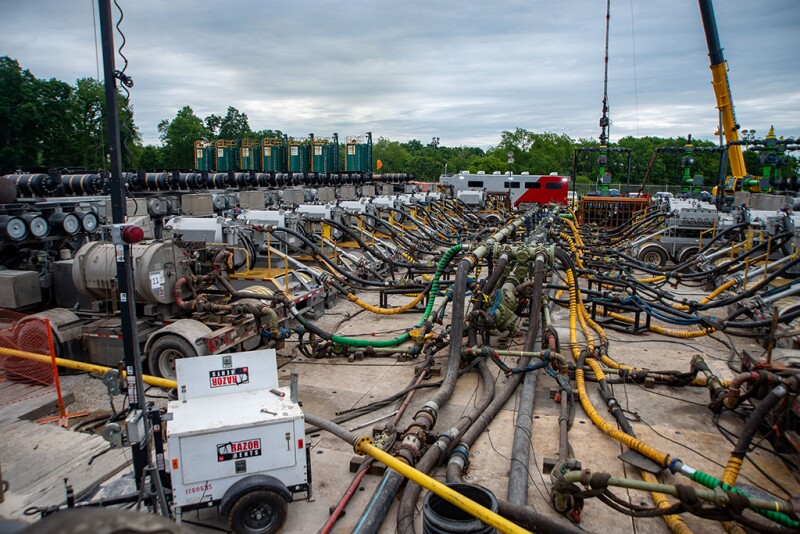

Houston-based Universal Pressure Pumping is in the midst of a year’s long modernization effort that has touched every major aspect of daily operations. The sweeping effort by the service provider, a subsidiary of drilling contractor Patterson-UTI, comes in response to the escalating demands that have been placed on North American pressure pumpers in recent years.

Horsepower availability remains the heart of their offering. But increasingly, even mid-sized service providers such as Universal have assumed additional responsibilities that have progressively made them into software developers, chemical analyzers, and now low-carbon solution providers.

Along these lines, Universal’s most important ongoing initiative is a field test of its first semiautomated hydraulic fracturing spread in the gas-rich Appalachian Basin with an undisclosed operator. The pilot is helping to bring Universal in line with some of its rivals in the US sector that have already adopted various layers of automated controls in recent years.

The big driver behind the trend comes down to the fact that unlike human operators, software doesn’t get distracted on a busy job site and can make split-second decisions on how to distribute horsepower based on demand and each individual pump’s operating thresholds.

The ultimate prize Universal wants from automation is to use as much natural gas as it can to run its dual-fuel units.