The Utah Frontier Observatory for Research in Geothermal Energy (FORGE) announced successful results from its first pair of stimulated horizontal wells—one injector and one producer—and said more testing will begin in a few weeks.

The project group, backed by the US Department of Energy (DOE), reported that a circulation test showed ample fluid flow between the well pairs, demonstrating the viability of an enhanced geothermal system (EGS) at the site in Beaver County, Utah.

“Enfranchising the knowledge gained from previous activities, and with advice from a diverse team of specialists from industry and academia, the Utah FORGE team was able to achieve outstanding results,” John McLennan, a professor at The University of Utah, who manages EGS research at FORGE, said in a statement.

He added that monitoring during the stimulations showed induced seismicity never exceeded a magnitude of 1.9, “falling well short of the threshold of felt seismicity.”

The success for FORGE follows the achievements of its private counterpart Fervo Energy, which is also drilling EGS wells in Beaver County. In 2023, Houston-based Fervo became the first company to show horizontal EGS wells can deliver commercial levels of energy and is planning to launch its first major 400-MW project dubbed "Cape Station" by 2026.

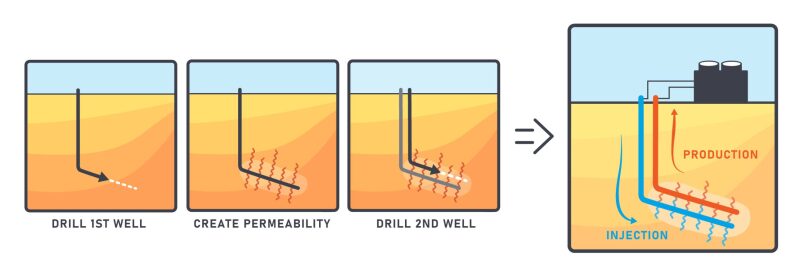

The FORGE project drilled its first injection well in 2020 to a vertical depth of 8,559 ft in hot, dry granite rock. In 2022, crews returned to hydraulically fracture three toe-end stages using slickwater. The production well, drilled in 2023, reached the same depth, with its lateral section landed about 300 ft above the injector.

FORGE confirmed connectivity between the wells with a circulation test run immediately following the drilling of the producer well.

In April, both wells received a “commercial-scale stimulation” over 2 weeks. The injection well had eight stages treated, including the refracturing of the three existing stages, followed by a four-stage treatment of the producer well.

The test wells used an unspecified amount of proppant, custom frac plugs, and multiple perforation clusters per stage, and various stimulation fluids were pumped for comparison purposes. A total of 118,000 bbl of nonpotable local groundwater was pumped into both wells.

Diagnostic technologies, including seismic mapping and fiber-optic cables, were used to monitor the induced fractures. This data allowed FORGE to select specific areas of the producer wellbore for perforation and stimulation, enabling it to enhance interwell connectivity.

A 9-hour circulation test using injection rates up to 15 bbl/min resulted in an 8 bbl/min output from the production well, translating to an efficiency rate of 70%. The test also recorded an outflow temperature of nearly 282°F.

FORGE described these results as “exciting” and expressed confidence that the well-pair is capable of generating EGS energy. A 30-day circulation test is planned for July.

As a DOE-sponsored project, all project data collected from FORGE are publicly available on the Geothermal Data Repository.