Wellbore deformation can occur at any stage in the life of a well. Whether a result of changes in temperature, pressure or tectonic forces, wellbore deformation may result in serious downhole issues such as restricted access for interventions or the loss of well integrity that may ultimately lead to premature well abandonment and significantly reduced economic performance. This article describes how proactive diagnosis of well deformation enables operators to understand the cause and severity of the issue, enabling them to adjust their strategy to overcome it and deliver safe, profitable production.

Understanding Deformation Events

Deformation events are often unseen at surface, and it may be very hard to know that a deformation event has occurred. There may be no loss of containment and no visible signs such as sustained annular pressures. Deformations are often found the hard way - during interventions. This often leads to significant delays and increased costs due to personnel and equipment on standby, often involving drilling rigs, frac fleets or stimulation vessels.

There are several potential causes of pipe deformation. Some of these are naturally occurring phenomena and conditions that are inherent to the specific geographic location and its geology, such as tectonic forces, formation compaction or swelling of salts/clays. Examples of this can be seen in numerous offshore fields where the depletion of reservoir pressure reduces the compressive strength of the formation such that it can no longer support the overburden or residual stresses contained within. The onset of such issues is particularly aggressive in gas and gas condensate fields where rapid pressure decline occurs more readily. Similarly, issues resulting from the swelling of formations are most common in areas with highly mobile aquifers that present a challenge to cementation and zonal isolation. Under these scenarios, early identification, and time-lapse quantification of the onset of deformation events, can enable operators to manage the situation and maintain safe production for extended periods, thereby maximizing the economic life of the well and return on investment (ROI). These well management activities may include adjustment of draw down or injection programs to help control the imbalance of forces, or to help prioritize production enhancing interventions such as re-perforation and water shut-off before access to the reservoir sections are lost.

Conversely, there are deformation-enabling factors that result from the specific conditions that are inflicted on the well during its operation either intentionally or by general human error. Such factors can have a significant impact, such as excessive pressure imbalance between the annuli and wellbore, forces exerted through pressure pumping activities, or thermal expansion during completion, stimulation and production. Examples of such imposed issues are highly evident in unconventional wells where frac induced interactions between wells is a common problem in every basin, globally. This issue is further compounded in basins where subsurface stresses are released as the structural integrity of the formation is broken down during the fracturing process. Similarly, thermally induced deformation events are more prominent in high temperature, high pressure (HPHT) wells during initial production as the colder completion fluids are replaced with much warmer production fluids resulting in significant thermal expansion of the metal tubulars across the entire length of the well. These events typically occur early in the life of the well, and often long before the economic breakeven has been reached. Under these conditions identifying the root cause of the issue and understanding limits of well access are critical to rapidly overcoming the issue, minimizing NPT, restoring production, and avoiding re-drills where possible.

These issues are not just evident in oil and gas wells, but also common in geothermal and disposal wells too. Furthermore, the factors affecting well deformation are typically present field wide rather than isolated to a specific well. To this extent, understanding the behavior of wells with the early onset of deformation issues often holds the key to managing surrounding wells and/or influencing the design and operation of wells that are yet to drilled and completed.

Typical Well Deformation

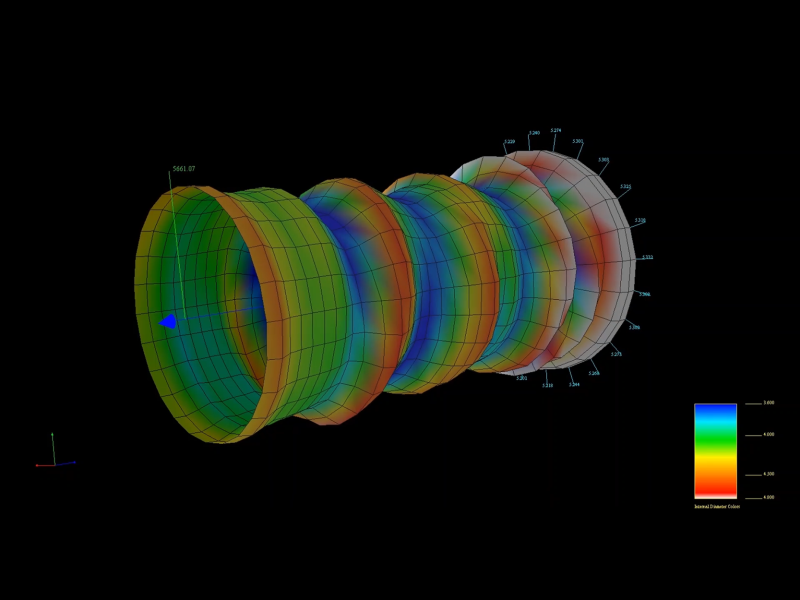

There are multiple types of wellbore deformation (Figure 1). The three most typical forms are:

- Shear deformation: caused by tectonic forces acting across the axis of the well and resulting in an offset in well trajectory above and below the fault plane.

- Bending: a localised departure from the centreline of the well, often caused by expansion of permeable materials such as clays and salts, or from interaction with neighbouring wells.

- Helical buckling: caused by axial forces that act in compression along the wellbore trajectory. These are often caused by thermal expansion during initial production.

As noted, none of these events will automatically lead to a loss of containment and they tend to only be found during interventions. However, if a single well within a field experiences these deformation events, there is a strong possibility of experiencing it on multiple wells due to some of the key drivers of these issues being field wide. The good news is that in most cases, these challenges can be overcome through the application of a quantified analytic technique called Pipe Deformation Analysis (PDA).

Quantifying Limitations of Access

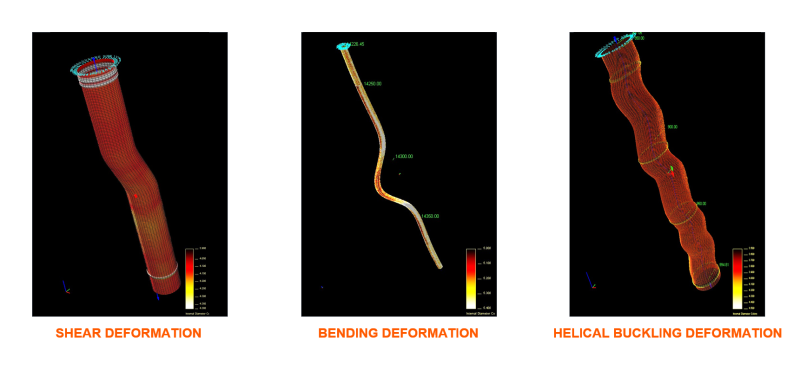

In this case study, an operator was mid-way through a routine plug-and-perf frac operation when they suddenly held up while pumping down the plug and gun assembly for their next stage. The hold-up depth was close to the liner hanger and initial thoughts were that this assembly may have been damaged. However, with live guns involved and the frac operation on standby, analysis of pipe deformation was also required in the event that the liner may have been sheared, buckled or deformed by other mechanisms.

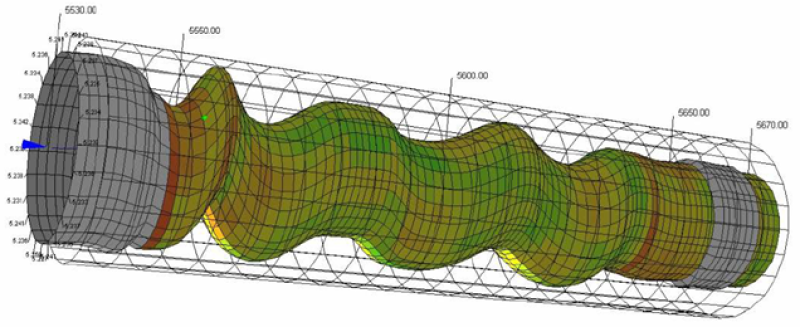

In order to do this, a 24-arm multi-finger caliper was deployed downhole together with downhole video imaging. This combination of video with multi-finger caliper data leads to enhanced interpretation and provides invaluable 360° pipe coverage to compliment the limited radial coverage available from a stand-alone mechanical caliper. Proprietary Pipe Deformation Analysis software was then utilized on the data acquired. This process confirmed the that the liner hanger was undamaged and revealed that the presence of helical buckling in the liner was the reason why the original plug and perf string was unable to descend to the target depth (Figure 2).

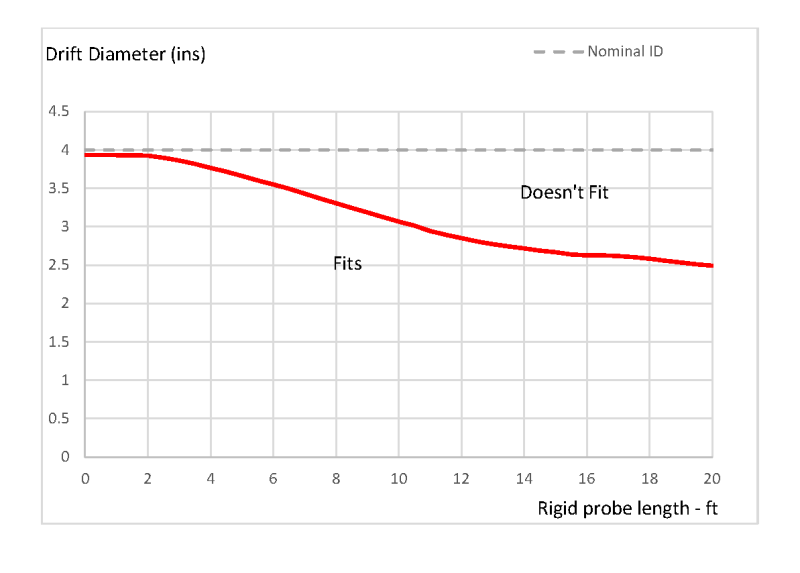

Furthermore, by simulating the passage of multiple BHAs through this 3D geometry, a drift analysis was provided to understand the limits for access and identify the optimal BHA to pass the restriction (Figure 3). This valuable information enabled the operator to design their plug and perf string to fit through the liner deformation, helping them put the operation back on track and deliver the well with minimum NPT and the frac completed to the intended design. The same drift analysis data was used to select an appropriate milling assembly resulting in successful removal of the stage plugs and access to all fractured stages. The well was then cleaned up, lifted, and placed onto production without any compromise to production performance. This result was a significant win for the operator as, thanks to only a limited delay in well delivery, the well provided similar ROI to its peers which would have otherwise been significantly reduced in the event of only achieving production from the upper stages, or had a complete re-drill been required.

Conclusion

EV’s Pipe Deformation Analysis can be applied across the life of a well. This advanced simulation enables operators to identify and determine the severity and risk of any wellbore deformation that may have occurred. This valuable information is key to maximizing the operating life of wells affected by deformation and optimizing interventions to minimize risk and maximize success. Through up-front data gathering, operators can increase productivity, defer re-drills, and reduce NPT during interventions to maximize the economic performance of their assets.

Visit evcam.com to learn more and to find your nearest EV representative and discuss how Pipe Deformation Analysis can provide the definitive, proactive service for de-risking well interventions.

References

SPE Asia Pacific Wells Week: Application of Advanced Well Entry Simulation to Improve the Efficiency of Abandonments by Tobben Tymons, 2019.

SPE Casing Deformation During Fracturing of Unconventional Wells Workshop: Utilizing Downhole Video, Multi-sensor Technology, and Advanced 3D Modelling to Evaluate and Overcome Casing Deformation in Unconventional Wells by Gabriella Griffith, 2021.