Reservoirs present plenty of complexity and mystery. Four oil recovery experts have helped remove some of those mysteries, taming the complex to boost production.

From developing preformed particle gels that improve conformance when fractures cause severe channeling to simulating enhanced oil recovery (EOR) processes in the reservoir to identifying the aqueous stability concept to demonstrating the distance polymer solutions can travel without degradation, the four 2024 recipients of the 2024 Improved Oil Recovery (IOR) Pioneer Award have made a “sustained and important contribution to increased oil recovery,” Randy Seright, New Mexico Tech, 2024 Pioneer selection committee chairman and 2008 honoree, told JPT.

Seright, four other previous recipients of the recognition, and 2024 SPE IOR Conference General Chairman Tom McCoy evaluated a field of 16 nominees for the lifetime achievement honor and selected four who have throughout their careers “made the most lasting and significant contributions to IOR,” Seright said. “It’s why we are where we are today with respect to IOR.”

The 2024 IOR Pioneer recipients who were honored during the biannual IOR conference in Tulsa in April are Baojun Bai, professor of petroleum engineering, who sits in the Lester Birbeck Endowed Chair at Missouri University of Science and Technology (Missouri S&T) in Rolla, Missouri; Mojdeh Delshad, research professor in the Hildebrand Department of Petroleum and Geosystems Engineering at The University of Texas at Austin (UT-Austin); Varadarajan Dwarakanath, team lead for chemical EOR at the Chevron Technology Center in Houston; and Stephane Jouenne, who previously led a TotalEnergies team dedicated to surface and subsurface research topics for polymer flooding and is currently CO2 capture project coordinator at TotalEnergies.

“It’s the most prestigious award given out in IOR,” Seright said.

Baojun Bai

Preformed Particle Gels

Bai’s major contribution to the field of IOR was developing preformed particle gels that can be used to plug fracs when fracture fluids are channeling to the wrong location instead of using chemical-reactive gels that may not set properly because of their sensitivity to contact with reservoir fluids, Seright said.

“By preforming the gel, you take care of that problem,” he said, noting that these gels also have potential for plugging wider fractures.

Bai told JPT his research group in PetroChina initiated work on the preformed particle gel technology in 1996 and successfully field tested it in 1999 in China before starting to “use this technology for all the fields.” The technology has since been used in thousands of wells.

He has also expanded the preformed particle gel technology to function in high-temperature, high-salinity conditions, CO2 floods, and sequestration efforts.

Bai holds a PhD in petroleum engineering from New Mexico Institute of Mining and Technology, a PhD in petroleum geology from China University of Geoscience in Beijing, a master’s degree in petroleum engineering from the Graduate School of Research Institute of Petroleum Exploration and Development in Beijing, and a bachelor’s degree in reservoir engineering from Daqing Petroleum Institute in Heilongjiang, China.

Bai said his advisors in PetroChina helped frame his interest in IOR. In his role at Missouri S&T, he is now shaping the next generation of IOR specialists

“Oil and gas is a really complex area, and you need a lot of knowledge” because the industry is more complex than simply drilling a hole and producing oil, he said.

“It is actually more complex than many other areas. There’s a lot of science and understanding behind it,” he said. “It’s a really, really fantastic area that you can go into.”

One reason, he said, is that conventional oil and gas recovery methods leave a great portion of the original hydrocarbons in place. This makes disciplines like IOR and EOR a hot topic, especially as new cost-efficient technologies are developed to produce more oil from current reservoirs.

“If we have good knowledge, we can produce it using EOR technology,” he said.

Mojdeh Delshad

EOR Simulations

Seright said Delshad, an expert in chemical flooding, has devoted a major part of her career to helping the industry understand and correctly simulate how various EOR chemicals and processes behave in the reservoir.

Delshad holds a BS degree in chemical engineering from Sharif University in Tehran, Iran, and MS and PhD degrees in petroleum engineering from UT-Austin.

Her search for a supervisor for her master’s led her to Gary Pope, who was then a new professor at UT-Austin and in 2006 became an IOR Pioneer honoree. He introduced her to surfactants and EOR.

“I had no clue what he was talking about,” she said.

She read up on surfactants, polymers, and EOR, found it interesting, and decided to work with him. Delshad carried out research work on three‑phase relative permeability for microemulsion in oil and water. When she graduated in 1986, oil prices were “miserable,” so she opted for postdoctoral work at UT-Austin. Rather than lab work, she focused on simulation and modeling and worked with the UTCHEM Simulator.

“It became the gold standard of chemical flooding modeling for the industry,” she said.

Costs and recovery factor are important for EOR projects, she said, but simple is also important for success.

“Don’t make it too complicated,” she said. “It’s already a complex process.”

Now back with UT as a research professor, she reminds her students of that concept. “You need to help (operators) be able to quickly and simply, without too much knowledge about simulation, face the challenges and find solutions for it,” she said.

Delshad also believes there is a future for IOR and EOR talents and has taught EOR fundamentals to engineers around the world.

“Is there any future for these technologies? Absolutely, there are, but they may not be used in the way they used to be in the past,” she said. “All the knowledge you learned can be applied elsewhere.”

Delshad is now working on hydrogen and CCUS storage. “I find it fascinating, the modeling and simulation of complicated processes,” she said, adding that what she’s working on now is “much more complex than injecting CO2 into reservoirs to produce oil.”

Varadarajan “DW” Dwarakanath

Aqueous Stability

Dwarakanath developed the aqueous stability concept while he was a graduate student at UT‑Austin and later played a key role in the Captain polymerflood project in the North Sea and the Minas chemical flood project in Indonesia, Seright said.

Aqueous stability is important in surfactant flooding because it helps ensure a surfactant formulation will flow through porous rock, he said.

Dwarakanath told JPT that while he was in university, surfactant aquifer remediation projects involved colloidal suspensions but that at the time, most didn’t realize “clear was better than colloidal suspension.”

He backed the aqueous stability concept as a young student by accident, he said, but is proud that the concept took off.

Dwarakanath later created customized surfactant molecular structures for the aqueous stable fluids he designed, which significantly reduced surfactant retention to enhance chemical EOR performance. That concept was validated in an alkali-surfactant-polymer pilot at the Chevron-operated Minas field in Indonesia. Injection of aqueous stable fluids there increased oil production from 40 to more than 1,250 BOPD and cumulative recovery by 22% of original oil in place, he said.

He was also a lead in the offshore Captain polymerflood project, which involved innovative IOR work like altering liquid polymer from an emulsion into a dispersion. This modification led to a 50% surge in chemical activity, a water content of under 5%, reduced plugging tendencies, and lowered logistical costs due to the enhanced concentration formula.

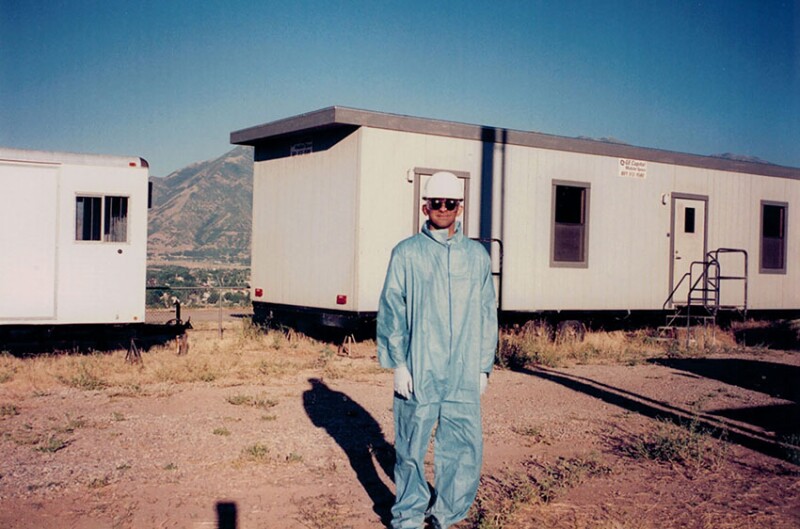

Dwarakanath holds a BS degree in mining engineering from the Banaras Hindu University in India and MS and PhD degrees in petroleum engineering from UT-Austin.

While his early university work focused on drilling, he said he finds IOR to be more exciting. “I wanted to see something more long-term than a drilling effort,” he said. “You’re done with the well as soon as you’re done drilling, so IOR makes more sense.”

The reservoir is akin to a mystery novel, he said, and if an operator is lucky, they get a long history of production. “It’s the best mystery novel you can have,” noting he has been working in IOR for about 3 decades. “It’s my way of being Mr. (Sherlock) Holmes for a reservoir.”

Stephane Jouenne

Mapping HPAM Transport

Jouenne has done “incredible lab work that’s answered a bunch of questions,” Seright said. “He’s the first to publicly demonstrate when and where you could transport” hydrolyzed polyacrylamide (HPAM) solutions.

Jouenne was key in driving the implementation of TotalEnergies’ Dalia and Camelia polymerflood projects offshore Angola. While preparing for the Dalia polymer pilot, he told JPT, he initially worked on quality control of the entire polymer chain.

“It was very educative because you have to know in detail the polymer dissolution process and the injection facilities,” he said. “Rapidly, a number of questions concerning the efficiency of this recovery method emerged.”

Those included: reliability of the injection process; oxidative and thermal degradation at the surface and in the reservoir; mechanical degradation in pipes, in chokes, and in injection wells; injectivity; oil recovery efficiency; impact of polymer on oil and water separation; and more, he said. These questions were the basis for his future work, which included developing a model for flow and viscous behavior of EOR polymers.

“Working on polymer solutions is fascinating because these fluids behave in an incredible way. Solutions are viscous like honey and elastic like a chewing gum. Trying to understand the behavior of such ‘complex fluid’ can occupy you for several lives,” he said.

That complexity also combines with the complexities of surface facility design and oil recovery in the reservoir.

“Working on EOR is a sequence of new worlds which open to you each time you progress in your comprehension,” Jouenne said.

Because of his involvement along the EOR chain from injection facilities to the well, to subsurface and oil production, he has a unique perspective and knowledge of EOR.

“Experts of each discipline call on you because you are the guy who understands this strange and unusual fluid,” he said.

He credits French scientist Guy Chauveteau for his initial learnings on polymers along with guidance from TotalEnergies EOR experts Danielle Morel and Maurice Bourrel for shaping his career.

Jouenne holds an MS degree in chemical and process engineering from ENSIC Chemical Engineering School in France and a PhD in physical chemistry of materials from Paris VI University in France.