This paper describes a matrix-acidizing campaign executed successfully in the Gulf of Cambay on the west coast of India. In initial laboratory tests and during simulation runs, the goal was to design a preflush/acid/post-flush system to best suit challenging reservoir conditions while also considering offshore logistics. After pumping the system in one well, the system design, pumping procedures, and volumes were modified to improve results further in the next well.

Introduction

The offshore field, located in the Arabian Sea off the western coast of India, has been on production since 1997 (Fig. 1 above). The field covers an area of 1471 km2 and lies 160 km north/northwest of Mumbai. The reservoir consists of a stacked series of sands deposited in the Lower Miocene and Oligocene. The field has up to 13 different Olio-Miocene gas-bearing sands separated by shales. Reservoir-sand permeability ranges from 100 md (in shaly beds) up to 5,000 md in clean sand beds. Because of the unconsolidated nature of the reservoir sands, gravel-pack screens are a typical well completion in the field.

Mineralogy

The formation can be described as iron-rich sandstone, with average iron-bearing chlorite content across 20 samples of 18%. Chlorite is a ferrous--dominant, minor ferric mineral and is partially soluble in hydrochloric acid (HCl). Acid dissolution of chlorite, an iron-bearing mineral, could create pore-plugging iron hydroxide precipitates. In the presence of chlorite clays, an increase in the iron-control-additive concentrations in the HCl preflush is recommended. Previous guidelines suggest using 5% HCl or 5% acetic acid as a preflush for sandstone matrix acidizing in chlorite-rich formations. On the other hand, this rock type contains a significant amount of hematite that occurs as the oxidation product of iron-rich detrital grains. Acidizing the ferric iron-rich hematite with HCl-based blends should be expected to generate ferric hydroxide gels, which could plug reservoir pores and pore throats, thereby lowering productivity.

Choosing the Right Acid

Many gravel-packed wells suffer production loss as a result of fines migration and precipitation of inorganic scales, presumably calcium carbonates (CaCO3). The most-effective means of removing CaCO3 scale is with acid (HCl or acetic acid, or less commonly with phosphoric acid) or calcium-chelating agents (carboxylate salts). Chemical treatment combined with coiled-tubing/nozzle injection can augment the scale-removal process, especially for very hard wellbore scale.

The only method available for removing clay and non-clay siliceous formation fines without rig involvement is the use of hydrofluoric-acid (HF) -based acid systems. Because of complex field mineralogy, this rock is susceptible to damage during acidizing with conventional HF/HCl mud acid. Conventional mud-acid systems will preferentially attack the clay particles, resulting in precipitation of secondary- and tertiary-reaction products. This precipitation will cause severe reduction of permeability and well productivity. Another aspect of these inherent problems is that the formations themselves are unconsolidated or poorly consolidated and therefore require gravel packs and screens for sand control. The action of mud-acid systems can result in further weakening of the formation.

A modified HF system using an organophosphonate acid (HV) has been proposed. The new system (HF/HV) is designed to use less HCl to convert all the ammonium bifluoride (ABF). The HCl concentration in this system is approximately 0.73% before it reacts with ABF. The system has sufficient acetic acid to convert the ABF, leaving approximately 3 to 4% acetic acid. Organic acid also slows down the development of the full HF. The unconverted ammonium fluoride would be converted deeper into the formation. The idea in using the new system is to minimize the risk of overacidizing the near-wellbore region and to extend the reaction for deeper penetration. The HF/HV acid system was mixed so that the equivalent strength of the HF was 1.5%.

Core Testing

A formation-core-flow study was performed to evaluate the regained permeability after HF/HV stimulation. A core pack of 1.5-in. diameter and 2.0-in. length in a core sleeve was used for the core-flow test. The test-fluid procedure was to first inject 5 pore volumes (PV) of the 5% ammonium chloride (NH4Cl) preflush water and then measure initial permeability; then, 5 PV of the HF/HV was injected, and then the final permeability was measured. Results of flow testing indicate that the HF/HV treatment improved permeability by 44.4%.

Acidizing History

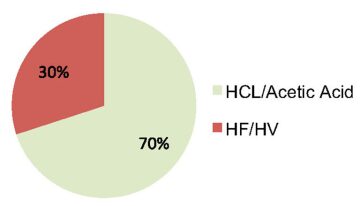

From 2006 to August 2010, seven HF/HV acid treatments have been pumped, and in one well (x-07), only 500 gal of 10% HCl was pumped to remove carbonate-scale precipitation. Post-treatment production showed a 70% production increase after HCl/acetic-acid stimulation and an additional 30% after the HF/HV. This probably means that HCl-soluble scales are the predominant problem in the field, compared with fines migration (Fig. 2). There is no carbon steel in the well completions, and pickling (rust-removing) treatment is not required. The HCl stage has been applied before the HF/HV to remove acid-soluble scales inside the tubing string and in the near-wellbore region. The following acidizing procedure proved successful

- (carbonate-scaling-removal stage): 7.5% HCl+ 10% acetic acid

- Main acid (formation-fines-removal stage): HF/HV

- Overflush: NH4Cl

- Tubing displacement: nitrogen (N2)

One well did not show any production improvement after the treatments; Well x-08 experienced gravel-pack failure. We have divided six HF/HV jobs into two categories: the best performers (initial production increase of greater than 100%) and the worst performers (initial production increase of less than 100%). Only one well, Well x-04, was treated without a NH4Cl spacer between the spearhead and main acid stages. This well is one of the three best HF/HV performers. This indicates that the spacer does not affect post-acid production performance.

HF/HV Jobs. All wells (except for Well x-08) have responded favorably to HF/HV matrix-acidizing treatments, with a minimum 50% production increase. The treatment effect lasts for at least 18 months. The difference in production response between the best and worst wells could be caused by the higher positive skin before the treatment in the case of the best performers. The average gal/ft and net pay are the same for both categories: 75 gal/ft and 15 m of net pay per well.

10%-HCl Job. The job was pumped in Well x-07. 500 gal of 10% HCl was displaced with N2. The post-pickling production of Well x-07 is comparable with the worst HF/HV wells. Six months after the treatment, the gas production was still 50% higher than before the treatment job. The fact that production increased after pumping a relatively small amount of HCl indicates the well’s proclivity to form HCl-soluble (carbonate) scales inside the tubing and in the near-wellbore region (gravel-pack screens).

Nitrified Acid Treatments: Acidizing Pressure-Depleted Wells

Several nitrified acid jobs were pumped in a late-December 2010 acid campaign, in addition to the previously mentioned cases. Wells with depleted reservoir pressure were chosen for this campaign. Additionally, these candidates suffered from liquid loading, and no separator was available on an offshore platform for unloading these wells. A pressure-buildup test was performed on each well to identify stimulation candidates, and, in all cases, wellbore damage was indicated. The atomized-acid technique has been proposed to avoid water-loading problems and to eliminate the skin. The acid was injected as a fine mist of droplets in the continuous nitrogen phase. A 2:1 nitrogen/liquid ratio was used.

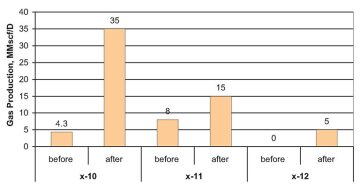

Well x-10. This well is a cased-hole gravel-pack completion with net pay greater than 400 m. A sudden drop in production was observed in 2009. Coiled-tubing intervention was performed to restore production in late 2009. An obstruction was encountered at the top of the gravel-pack screen (2677 m). Attempts were made to clear the obstruction by pumping 15 bbl of 7.5% HCl. Though the obstruction could not be cleared, there has been a gain in production; original production level was restored after the intervention (38 MMscf/D). A similar drop in production was observed in April 2010. Average initial rates dropped to 20 MMscf/D in June 2010 and to 4.3 MMscf/D in September 2010. Taking into account the previous success with 7.5% HCl, it was decided to pump the same acid formulation again. It was believed that the tubing and gravel-pack screens were plugged with HCl-soluble CaCO3 scales. Again, an atomized acid treatment was pumped, with 7.5% HCl dispersed in nitrogen (70:30 nitrogen/acid ratio). The well started to flow almost immediately after the treatment was completed. Several weeks after the job, the well was producing at 35 MMscf/D. Pre- and post-treatment production is shown in Fig. 3.

Well x-11. This is a fracture-pack completion with net pay greater than 30 m. The well showed the first sign of water breakthrough in January 2008. The water/gas ratio has increased to 80 bbl/MMscf as compared with an earlier water/gas ratio of 2 to 33 bbl/MMscf. From a pressure-buildup survey, a skin factor of +17.2 was obtained. The atomized HV/HF treatment was proposed to target damage incurred during production, such as fines migration and damage associated with CaCO3 scales.

The atomized HV/HF treatment was performed as follows:

- Spearhead (carbonate-scaling-removal stage) 7.5% HCl +10% acetic acid (10 gal/ft)

- Spacer: NH4Cl (500 gal)

- Main acid (formation-fines-removal stage): HF/HV (20 gal/ft)

- Tubing displacement: N2

The acid stage was nitrified to a 70:30 ratio for better coverage and fluid recovery. The treatment was successful and nearly doubled the pretreatment production rates from 8 to 15 MMscf/D. This increase provided data that further proved that fines migration and CaCO3 scales were the primary damage mechanisms limiting production in this field.

Well x-12. This well is a gravel-pack completion in 7-m sand. The initial production was 11.47 MMscf/D with 20% water cut through a 90/64-in. choke. The reservoir pressure recorded in October 2012 was only 745 psi, significantly below hydrostatic pressure (3,000 psi). As a result, the well was unable to flow through 3½-in. tubing with a backpressure of 400 psi. Before the stimulation treatment, the well production dropped to zero. It was recommended that the interval be treated with 50 gal/ft (screen length) of the HF/HV system mixed so that the equivalent strength of the HF was 1.5%, plus a spearhead of 7.5% HCl +10% acetic acid and an NH4Cl spacer between the stages. All fluids were nitrified to a 70:30 ratio. The well, which had been virtually dead, started to flow almost immediately after the stimulation treatment. Two weeks after the job, the well was producing 5 MMscf/D of gas (Fig. 3). The post-treatment production suggests that the HF/HV system removed the damage.

This article, written by JPT Technology Editor Chris Carpenter, contains highlights of paper SPE 164631, “Overcoming Challenges While Acidizing Sandstone Formation Successfully in the Gulf of Cambay, Offshore India,” by Sergey Stolyarov and Anwar Alam, Baker Hughes, prepared for the 2013 SPE North Africa Technical Conference and Exhibition, Cairo, 15–17 April. The paper has not been peer reviewed.