Explanations for how fracturing works are often based more on the imaginations of experts than observations of the damage caused by hydraulic pressure.

A rare study that spent the tens of millions of dollars required to get a direct look at horizontal wells drilled in South Texas (URTEC 2670034) described its findings as “very different from the simple view of the stimulated reservoir volume commonly modeled or predicted with current fracture models.”

The paper added: “The absence of proppant on most of the hydraulic fractures indicates that proppant emplacement is quite different from idealized transport model predictions.” And, “The apparent side-by-side propagation of closely spaced, near parallel hydraulic fractures also differs from the output of currently accepted fracture models and may call into question the role of stress shadowing in hydraulic fracture propagation.”

When the paper was delivered at the Unconventional Resources Technology Conference (URTEC) last August, it generated a lot of buzz among experts starved for direct observations. This emerging area of study will be the topic of a panel discussion during the plenary session of the SPE Hydraulic Fracturing Technology Conference, which is being held this week in The Woodlands.

Since the 2014 test in the Eagle Ford, a lot has changed as the center of the unconventional universe has shifted to the Permian Basin, where a research consortium of oil companies with government support has created a hydraulic fracturing test facility to observe fracturing on a well pad there. It offers a look at how fracturing is done now in the industry’s hottest play, and is also likely to add to the questions.

“Whenever we directly measure created hydraulic fractures or the stimulated reservoir volume, we are always surprised and our mental images are altered and begin to change,” said Kent Perry, executive director of the Gas Technology Institute, which is involved in the Permian Hydraulic Fracturing Test Site.

|

|

One regular theme in these reports is that “the number, location, dimensions, and characteristics of the created fractures, and altered natural fractures, is very complex,” he said.

The ConocoPhillips test well in the Eagle Ford concluded that much of the permeability created that allowed production in the ultratight rock was due to hydraulically created fractures.

Distinguishing fractures created by hydraulic pressure from those caused by drilling and natural fractures required a “deductive process” to determine how the fracture was created. The paper said natural and hydraulic fractures were on different orientations because stress fields changed over time, and the older, natural ones often had been filled by minerals.

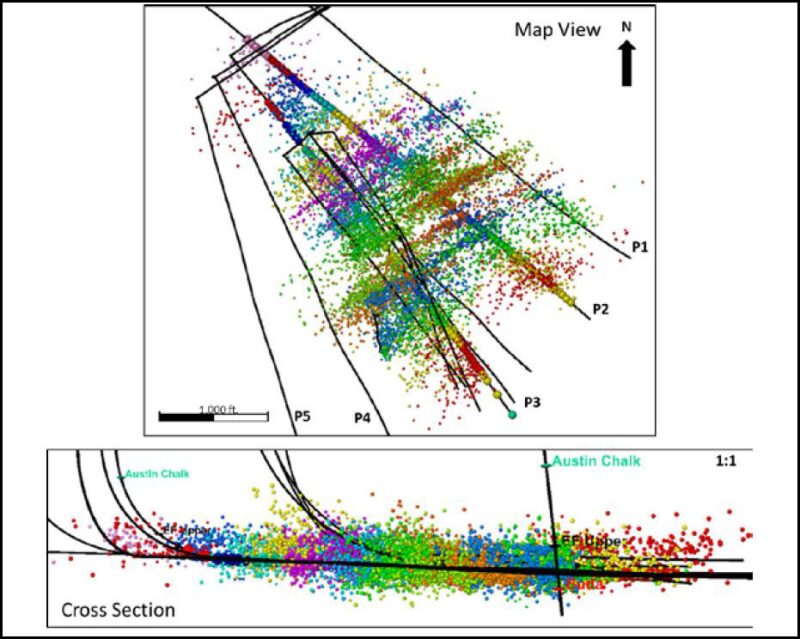

Multiple hydraulic fractures often occurred nearby, with individual fractures branching off along parallel paths.

The network of fractures tended to be wider than taller. The fractured rock surfaces were rough but contained little proppant. While the study found microseismic images coincided with some swarms of created fractures, it missed others. The report suggested measures based on microseismic are not likely to be a reliable way to quantify fracture density or effective permeability.

After describing instances where microseismic failed to observe highly hydraulically fractured areas, the report said “this observation is not meant to imply that microseismic data is not useful in delineating the character and morphology of fracturing; it is simply insufficient to explicitly define the outcome in a quantitatively reliable manner.”

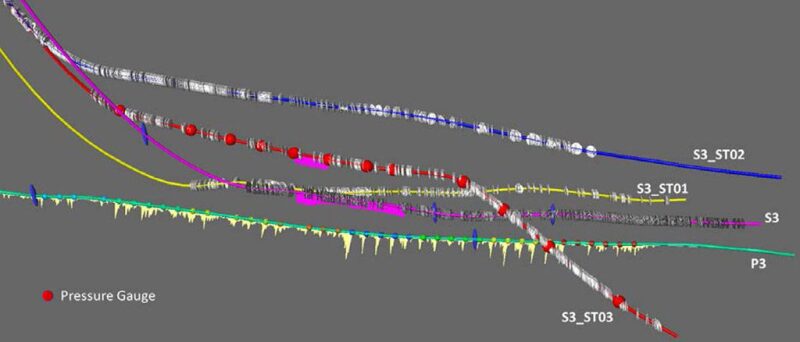

Even with four producing wells and five observation wells equipped with the latest monitoring equipment, ConocoPhillips’ research team was left wanting more. The observation wells were all above a single well raising questions about fracturing below those wells.

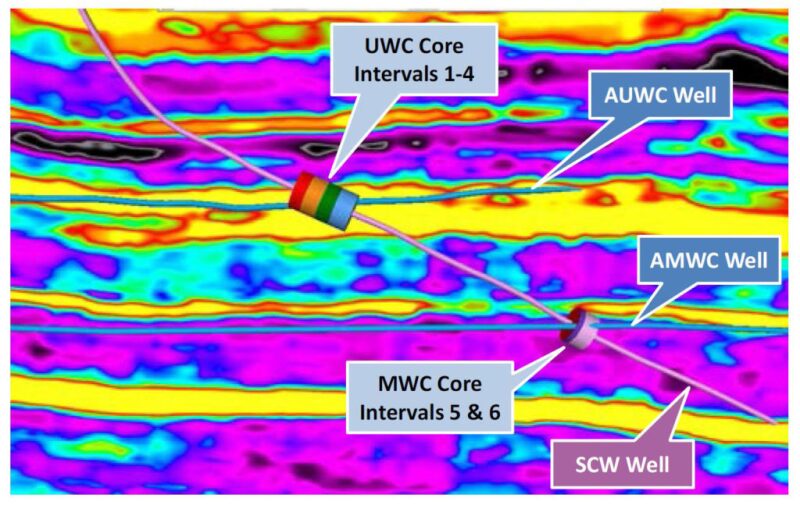

The Permian project, led by Laredo Petroleum, had a budget of $25 million and featured two wells closely observed by a slanted observation used to collect nearly 600 ft of core samples from sections of two wells, one in the upper Wolfcamp and the other in the lower Wolfcamp.

The test setup was reported at the 2017 URTEC conference (URTEC 2697483) and the Permian group plans to report its latest results at this year’s conference. One of the rewards for the 10 operators and service companies supporting the work was exclusive access to the results before they become public. A public report is ultimately required because the US Department of Energy’s National Energy Technology Laboratory is involved.

As new information comes out, those building models scramble to keep up. “While much progress has been made, the complexity has continued to increase faster than modeling capability,” Perry said.