A major challenge during drilling operations is the occurrence of twistoffs on bottomhole assembly (BHA) components. To overcome this challenge, a study was performed of twistoffs experienced on BHA components. Based on the findings, drilling operations and recommendations were provided to reduce or eliminate twistoffs related to suboptimal drilling parameters. This analysis will help drilling engineers and personnel foresee vibration dysfunctions and act accordingly with the use of BHA dynamics software to optimize drilling parameters before and during drilling.

Twistoffs Caused by Drillstring Vibrations

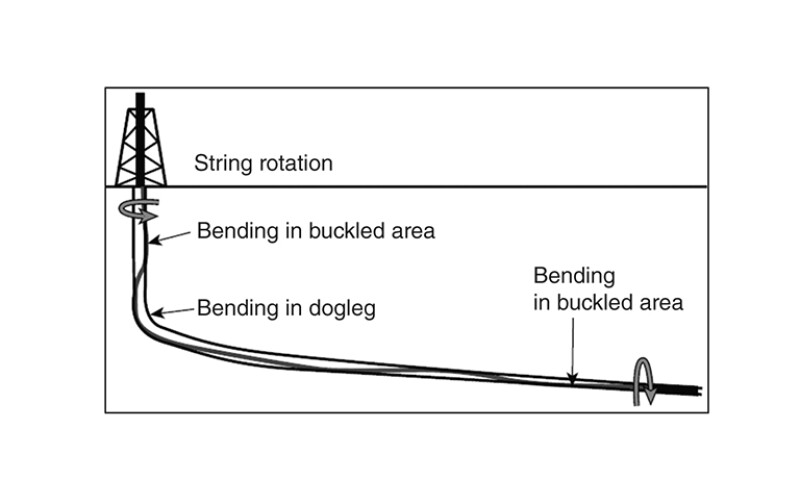

Field experience has shown that unwanted drillstring vibrations lead to failures, especially stick/slip (torsional vibrations) that occurs approximately 50% of the time during drilling.