The capacity to monitor flow behavior at the stage level in multistage hydraulically fractured wells delivers tremendous insight for optimizing field development, which is critical as operators face heightened pressure to increase production amid persistent economic discipline.

Historically, however, stage-level flow mapping to deepen understanding of complex reservoir performance, optimize well spacing, and mitigate direct interwell communication, or frac hits, was accessible only through the installation of production logging tools, fiber-optic-enabled distributed temperature surveys (DTS) or distributed acoustic sensing (DAS), and other costly and highly intrusive diagnostic methodologies. Compounding the costs are the extensive downhole modifications required and the failure risks. These these and other approaches only generate inferred, rather than direct, measurements of the flow profile.

Alternatively, field-proven ultrahigh-resolution nanoparticle tracer technology is providing operators a robust and nonintrusive medium that delivers precise and near-real-time measurement of stage-level flow behavior, well beyond the capabilities of DNA sequencing technologies and conventional chemical-based tracers. Moreover, the nanoparticle tracer technology does so at a comparable cost that essentially equals out to a rounding error in the total costs of contemporary multistage stimulations and completions.

Bolstered with advanced data-driven diagnostics, the distinctively tagged and nonradioactive tracers are engineered with subatomic spectroscopic measurement techniques to map the distribution of well production and the performance of the individual stage, while also qualifying overall reservoir condition and any cross-well interference.

The 0.1–1-μm-sized nanoparticles are deployed unobtrusively with the frac fluid stream, requiring no surface or subsurface modifications. Being nonradioactive and nonhazardous, they are not subjected to regulatory restrictions or special handling requirements. Once in the fracture network, the nanoparticles maintain stability at reservoir temperatures of up to 2,000°F and closure stresses as high as 10,000 psi.

During daily sampling of flowback fluid, returned tracers are separated from the sample and placed in a proprietary analytical subatomic spectroscopy instrument that quickly produces elemental composition and crystallinity results, which detect distinctive fingerprints at each of the nanoparticles to identify or correlate tracer recovery with production flow. The subatomic measurements in tandem with advanced geomechanics, onsite laboratory analysis, and big-data diagnostics provide actionable performance-flow-profile data to help operators right-size well placement and field development strategies while reducing the costs of multistage stimulation and well completions.

Once-Inaccessible Data

Unlike soluble chemically based tracers, the nanoparticle tracers remain intact within the fracture network, thus enabling continuous on-site monitoring of flow behavior for up to 9 months after the initial deployment. Conversely, once pumped, temperature-limited liquid tracers tend to disseminate quickly and flush from the proppant pack, reducing the effective monitoring time significantly.

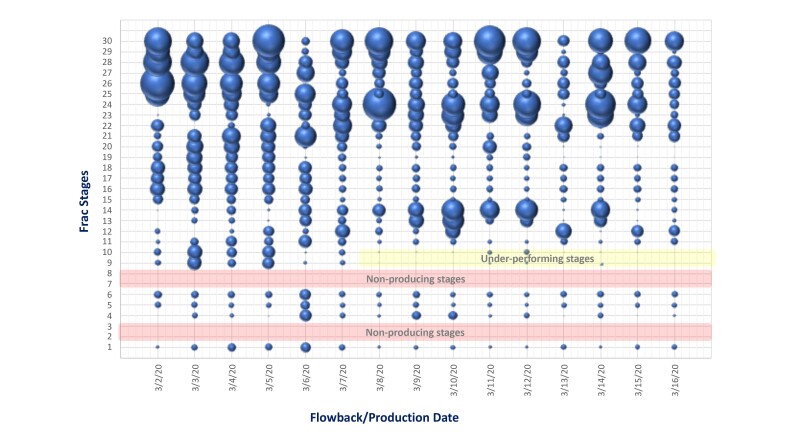

Fig. 1 shows protracted nanoparticle tracer data vs. time profile of a representative multistage Eagle Ford well, highlighting the high-resolution graphics that clearly depict once largely inaccessible stage-by-stage flow behavior. In this example, 30 stages were monitored daily over a 21-day period, with the size of the bubble reflecting the production volume/day of each stage.

The ultrahigh-resolution nanoparticle tracers convey significantly more reservoir fracture information, from the flow characteristics to the conductivity of the fracture, providing performance-flow-profile data that enable operators to enhance well placement and field development strategies while reducing costs.

Right-Sizing Lateral Placements - Permian Basin

As the correct placement of the lateral is critical to maximizing drainage of multistage unconventional wells, stage-level mapping of flow behavior at the onset of field development provides valuable insight that can help ensure higher returns on investment as new wells are completed and produced. The capacity to definitively analyze the performance of individual stages in the pre-existing "parent" well provides a wealth of data that can be incorporated to shape optimal lateral placement, lateral length and stage spacing of subsequent "child" wells.

Detailed stage-level flow profiles generated by diagnostics of returned nanoparticle tracers proved invaluable in a planned multiwell development in a less-delineated section of the Permian Basin in Texas’ southern Reeves County. The primary objectives of the initial 52-stage well were to gain detailed stage-level information on reservoir quality and characteristics to help guide the well landing, stimulation, and completion strategies of future wells, while remaining within tight budgetary confines. With limited offset data available, avoiding communication with wells in adjoining operators’ acreage was crucial.

Based on tracer recovery analytics, closely resembling that of pseudo-openhole log data that are rarely collected in typical unconventional reservoirs, the completed fracturing stages, for the most part, contributed in varying degrees to overall production. Although tracers were recovered successfully from all stages, the recoveries were significantly lower from stages 20–27, suggesting poorer reservoir quality in that portion of the relatively nonlinear horizontal section.

By coordinating tracer recoveries, representative of rock quality, completion effectiveness and subsequent oil production correlated with depths, the tracers can be used to navigate lateral placement in the better-producing areas of the leasehold.

Moreover, recovery data verified a generally held assumption on the flow behavior of shale wells that nearer-to-surface heel stages initially came on line quicker, and at higher rates than the toe stages. As exhibited in the tracer-generated profile, farther afield toe stages 1 through 19 began communicating, contributing significantly higher production rates than their heel counterparts. The production spike from the toe stages dictated more frequent sampling and analysis, which offered extensive insights on flow behavior changes across the entire lateral over longer periods of time.

Recovered tracer diagnostics illustrate that phenomenon on a granular level in Fig. 2, which shows the appreciably higher water flow during the first month of production (left), while the right graphic breaks down the later oil recovery profile. The darker green areas reflect higher recoveries and production of water and oil, respectively.

The transcendent data derived from the stage-level flow profile of the initial well provided a guideline of sorts with myriad options to guide the drilling and completion strategies of the planned infill development campaign. For instance, the overall flow profile suggested the first changed variable should be landing the lateral higher to ensure all stages are encountering the sweet spot. Landing the lateral higher, with a corresponding focus on the higher-producing stages, will likely avoid the added costs of completing stages that are not performing at optimum levels. The tracer recovery-depth relationship, likewise, suggests the cut points be set to maintain lateral placement above 9,900 ft to determine if doing so will exploit better reservoir quality (Fig. 3).

Furthermore, the data suggested increasing interstage spacing in subsequent wells may be desirable, as completing fewer stages within the sweet spot would reduce costs while achieving the same or better production.

Assessing Frac Hits - Eagle Ford, Delaware Basin

Infill development of tightly spaced multiwell pads and abutting lease boundaries have increased the risks of direct frac-to-frac communication, which is responsible for billions of dollars in lost production revenue. Field data have shown the nanoparticle tracers a viable alternative to offset well pressure gauges, production logging, or fiber-optic measurements in not only detecting interwell communication, but precisely identifying and characterizing the type and severity of said event to determine what reactive measures should be taken to optimize well-spacing designs.

Importantly, the vast majority of frac-hit signal characteristics are, in fact, fluid migration between the parent and newly drilled child well, which not only has a minimal and short-lived impact on reservoir drainage, but without it, a disproportionate area between the wells would be unstimulated, leaving reserves stranded. As shown in Fig. 4, frac-communication signals can have differing meanings with different impacts on production and estimated ultimate recoveries (EUR).

Post-frac diagnostics of returned nanoparticle tracers consistently demonstrate the capacity to assess whether detected events are direct frac hits or fluid migration. That determination gives operators the data necessary to decide whether to modify spacing or make other development modifications.

Therein lies one of the most glaring differentiators between the nanoparticles and conventional tracers, which are limited to chemical measurement techniques at a molecular level, thereby rendering them prone to delivering false frac signals. For example, in a multistage well stimulated with a zipper frac most of the pay zones are hydraulically fractured sequentially. Accordingly, a stacked pay well includes the predominant fracture with proppant, along with a discrete fracture network with very small open fissures. Chemical tracers tend to percolate deeper into these often-microscopic apertures, typically resulting in erroneous frac-hit signals, implying that all the fractures are communicating and drawing down production. What usually follows are hasty reactive measures, such as pumping far-field diverters, to seal off wrongly detected interwell communications, not only increasing costs significantly, but potentially harming production and EUR rates.

By contrast, distinctly tagged returned nanoparticle tracers clearly substantiate when reactive measures are necessary, as reflected in an Eagle Ford development where the technology was deployed as part of a zipper frac application on a five-well pad with 1,000-ft well spacing.

The tracers were pumped in a 30-stage well with tracer recoveries from four offset wells analyzed over 21 days of flowback sampling. The recovery analysis showed extensive direct frac hits on several stages of two offset wells, indicating interwell spacing was too narrow. Seven stages exhibited strong production rates, while another three were shown to be underperforming.

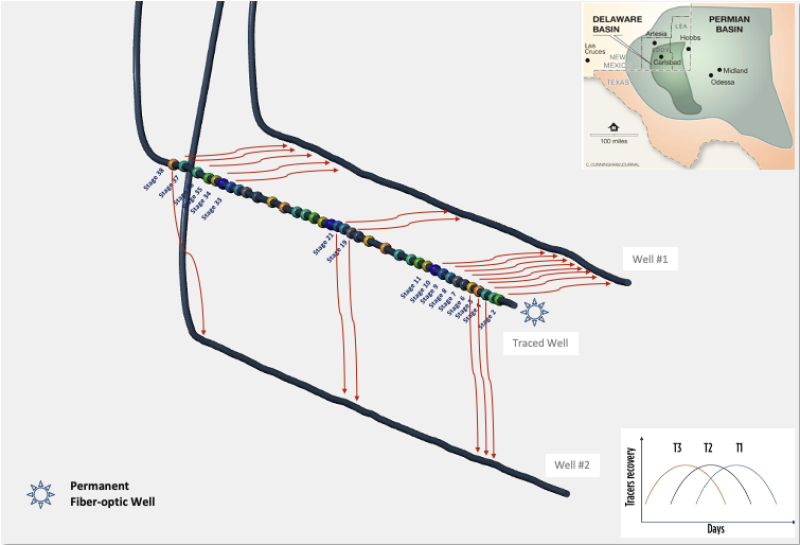

Similar results from an application in the New Mexico portion of the Delaware Basin led to a recommendation to re-evaluate both vertical and horizontal well placement strategies. Early in field development, the tracers were part of a sweeping investigation that included downhole fiber optics to determine optimum spacing on one well with a combined five toe stages and 800-ft horizontal spacing. The nanoparticles were first pumped along with chemical tracers, which were shown to deliver insufficiently low frequency, while fiber damage from the wireline plug-and-perf operations compromised results. Contrarily, as shown in Fig. 5, subatomic analysis of nanoparticle tracer recoveries showed direct frac hits between the traced horizontal well and the offset well, which prompted a re-evaluation of well-placement strategy.

Conclusion

The field-proven capacity of the ultrahigh-resolution nanoparticle tracer technology, abetted with the latest in data-driven diagnostics, to deliver precise stage-level flow profiles has advanced the capacity of multistage hydraulic fracturing stimulations to further increase production in horizontal, deviated, and vertical wells.

Visit www.quantumprot.com to learn more about how the FloTrac ultrahigh-resolution nanoparticle tracer can help maximize the value of your unconventional asset.

References

SPE-212319 -"Integration of Fracturing Pressure Diagnostics with Multi-Well Smart Tracer Program for Hydraulic Fracturing Stimulation and Diversion Efficiency Assessment" by T. Shokanov and J. Oliver QuantumPro, Inc.; D. Pena, Petralis Energy Resources; and A. Shokanov, Abai University, presented at 2023 SPE Hydraulic Fracturing Technology Conference and Exhibition (HFTC), 31 January–2 February 2023.

"Stage-level flow assurance helps refine Permian field development strategy," by Denna Callahan, Tall City Exploration, and Talgat Shokanov and John Oliver, QuantumPro, Inc., World Oil, September 2021.

"Smart Tracers Yield Stage-Level Insights," by Talgat Shokanov and John Oliver, QuantumPro, Inc. and Prof. Adilkhan Shokanov, Abai University, American Oil & Gas Reporter, February 2021.

Talgat Shokanov is CEO of QuantumPro, Inc., which he founded in 2017, following a 15-year career at Schlumberger, where he held a variety of international assignments. He previously spearheaded the global business and technology development of Schlumberger's cuttings re-injection via hydraulic fracturing unit, including subsurface engineering, disposal domain mapping, diagnostics, and monitoring analysis. Shokanov is widely recognized for technical expertise in multiple fractures mechanics, fracturing pressure analysis, and containment assurance. He holds numerous patents and has authored over 50 technical papers in complex fracturing. He is a recipient of the Prestigious SPE Award for Distinguished Contribution. He holds BS and MS degrees in petroleum engineering from Satbayev University in Kazakhstan.

Posi Jejelowo, VP of business development for QuantumPro Inc., has spent over a decade of his career focused on assisting operators to improve all aspects of their hydraulic fracturing programs. He has held operational, technical, and business development positions at Schlumberger, Weatherford, and Biota with key focus on frac diagnostics and frac-monitoring technologies. Jejelowo has monitored unconventional wells in nearly every basin in North America and is well-known for his efforts to improve the way our industry designs well completions. He holds a BS in chemical engineering from The University of Texas at Austin.