Human factors is a broad technical discipline focused on enhancing people’s performance in complex organizations where people interact with equipment and processes over time and across levels of hierarchy. Despite this relatively clear definition, human factors is still poorly understand and doesn’t yet yield the full potential that the practical insights and actions can produce.

Despite a substantial effort on the part of many industry bodies, including the UK Energy Institute (EI) and the International Oil and Gas Producers Association (IOGP), to raise awareness of human-factors principles, with some exceptions in a few organizations, progress on implementation has been slow. Momentum is now finally building with the formation of the Human Performance Oil and Gas Group (HPOG), which is designed to be an industry membership organization modeled on the highly successful Dropped Objects Prevention Safety initiative, DROPS. Its purpose is to embed human factors concepts into practical organizational processes and operational procedures.

There is a common misconception that human-factors skills are solely for frontline employees and once suitably trained, their behavior will change and performance will improve. This approach rests on the belief that the behavior of frontline operators is the source of all problems, which is wide of the mark. Human factors is a challenge for the organization as a whole and extends beyond simply understanding how the human brain works or silver-bullet solutions such as training crew resource-management skills.

Human Factors Competency in Exploration and Production

Competency in human factors is all too often focused on frontline operators, and the importance of human-factors skills among other groups is underappreciated. To be truly effective, human-factors principles have to be implemented throughout an organization. As part of its work to integrate human factors into the fabric of an organization, HPOG has identified nine different communities that would benefit from appropriate levels of human-factors knowledge and skills. These range from executive leadership through operational-site managers down to those on the frontline, but appropriate knowledge and skills are essential in the engineering and design functions; health, safety, and environment (HSE) and quality; supply chain; and HR and training functions. In addition, the HPOG is developing a recommended practice that proposes three levels of proficiency within an organization:

- HF experts who hold professional qualifications are discipline leads and are responsible for strategy, implementation, and guidance.

- HF champions with an intermediate level of competency support implementation of the strategy at regional, functional, and site levels.

- Role-specific HF awareness is promoted across the entire organization.

We observe a general scarcity of formally qualified human-factors professionals within exploration and production. In part, it can be seen in the way that language is used in reports and technical standards, specifically the use of indefinite adjectives, such as “inadequate” as a descriptor for apparent shortcomings in procedures and risk assessments, and attaching the label of “human error” as an explanation rather than as a starting point for deeper inquiry into the circumstances surrounding an incident.

We can also see it in the lack of systematic analysis of human factors in major incidents, the most notable being the president’s and chief counsel’s reports on the Deepwater Horizon disaster; these omissions were subsequently rectified in the US National Academies report and in Volume 3 of the US Chemical Safety Board’s (CSB) report. There were other missed opportunities for deeper analysis and valuable insights from which industry would have benefited greatly as evidenced by the gaps in the reports on the December 2009 Bardolino incident, the August 2009 Montara blowout, and the July 2013 South Timbalier Block 220 blowout.

There is a lack of resourcing of human-factors expertise in exploration and production in contrast to that in nuclear, chemical, airline, and air-traffic management. For example, the UK National Air Traffic Services (NATS) organization employs a team of nearly 30 human-factors-qualified experts (Skinner 2016); their team carries the tagline “People create safety.”

Where present in exploration and production, human-factors expertise tends to reside mainly within large operators, drilling contractors, and service companies. Some organizations have people working in central teams; others may have a large internal but relatively lightly qualified team relying on external academics and independent advisors. The drawback with this arrangement is that they are relatively ill-equipped to offer thought leadership and to commit time and skills to support joint industry efforts. Some organizations have human-factors engineers focused on a specialty such as human factors in design and are not generally involved with incident investigations or a broader set of human-factors topics.

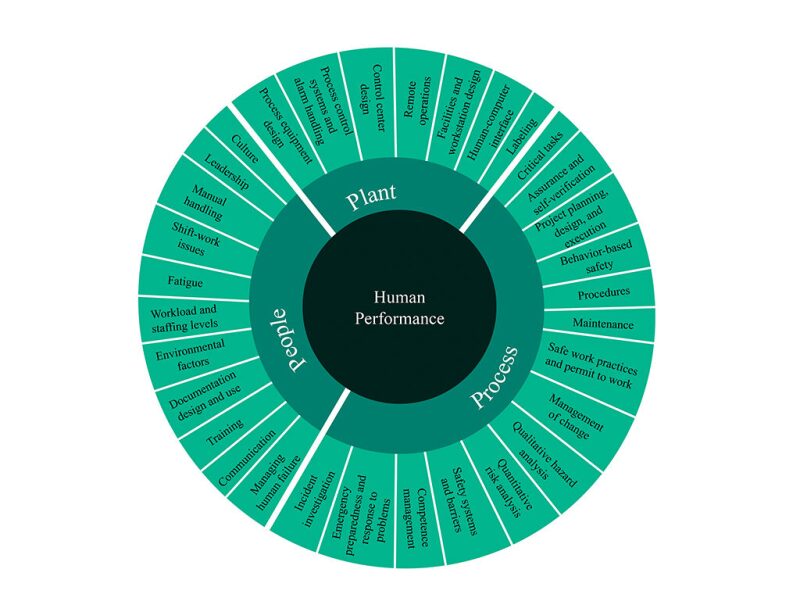

The scope of human factors is wide-ranging. Guidance published by the Center for Chemical Process Safety lists 32 human-factors topics while the HPOG internal effort has identified more than 60 topics. Its very breadth means that an individual is unlikely to possess sufficient in-depth expertise in all the fields to cover the domain effectively, which results in specialization and potentially compartmentalization.

Currently, the generic competencies of HSE and operational professionals exclude in-depth education in human-factors matters. Indeed, human factors is barely mentioned even in the Institution of Occupational Safety and Health (IOSH) diploma, and rarely, if ever, addressed as a topic in engineering degrees. The consequence is that certified HSE professionals and engineers are unlikely to have a solid foundation of human factors as part of their professional development.

In terms of what has already been achieved within the drilling community, the International Association of Drilling Contractors (IADC) has held several conferences on human factors, and the topic has featured strongly in their Health, Safety, and Environmental Technology conferences. IADC has also strongly promoted the uptake of human factors in well-control training.

The SPE organized a July 2012 summit on “The Human Factor: Process Safety and Culture” which produced an SPE Board-approved technical report (SPE 2014).

In late 2014, SPE organized an Applied Technology Workshop in London called “Getting to Grips With Human Factors in Drilling Operations” with an accompanying conference paper (SPE 173104). A joint-industry project produced a roadmap for drilling automation which addressed human-systems integration; it was produced under the auspices of the SPE Drilling Systems Automation Technical Section (SPE 173010). There have been numerous other SPE/IADC Drilling Conference papers, peer-reviewed journal papers on human factors topics, and case studies in SPE Drilling and Completions.

What Does This Mean in Practice?

In terms of guidance and literature, the industry has made some significant strides. The Energy Institute has published more than 50 documents on various human-factors topics from Briefing Notes to detailed guidance on how to conduct Safety Critical Task Analysis. The IOGP has published a number of important reports on general aspects of safety leadership, human factors, and investigations (IOGP Reports 453, 460, 621) and videos (Weak Signals) addressing the integration of human factors into well control (IOGP Reports 476, 501–503). Yet, despite these endeavors, the challenge remains to deliver an informed and systematic integration of those recommendations into robust and enduring organizational processes and systems.

Human factors is a discipline that requires professional competency. It covers many topics from design to leadership to decision making and contains diverse schools of thought. People trained in one specialty tend to underappreciate or even dismiss others. This leads to divisions and lack of common language and makes the unification and operationalization of the discipline challenging. The compartmentalization of expertise and the limited number of qualified human-factors professionals, combined with their limited operational experience, affects our ability to lead with human-factors excellence, in contrast to the way we lead in engineering excellence.

Yet, experience from other industries suggests that an investment in human factors offers real, practical solutions that help to reduce risk and save money. To make progress, the effort requires a critical mass within the community to have a common understanding of what we are talking about. Frontline personnel, including HSE, operations, and engineers at a minimum, require basic knowledge and practical skills that go beyond simple awareness.

To achieve this, through the work of HPOG (and EI, IOGP, and SPE), the industry can create a standardized approach with easily available and ready-to-use content. We must build on technical journals and reports to bring accessible educational materials to the wider community. These resources will enable the practical integration of tools and methods into established organizational processes.

Substantial gaps exist in the application of human factors to many topics, including incident investigations. The opportunity lies not only in improving the quality of insight from undesired events but shifting the energy and effort into learning about the precursors of accidents when nothing goes wrong. The challenge is therefore twofold: first, to develop a common understanding across our industry to enable this change with the limited number of qualified experts, and second, to integrate human factors into core processes to reduce risk, improve efficiency, and accelerate proactive learning.

Where Should We Go From Here?

Parts of our industry recognize the importance of human factors and several organizations have subcommittees advancing various human-factors topics. For example, SPE has an active Human Factors Technical Section and IOGP has a human-factors subcommittee which regularly publishes guidance documents. The Energy Institute, Certified Process Safety Professionals, the Center for Offshore Safety, Step Change in Safety, IADC, and others publish or organize human factors-focused papers and events. However, these efforts typically target middle management. There is a lack of informative and practical material targeted at executive leaders whose understanding and leadership is essential in the long term to putting human factors into the mainstream.

Those efforts undertaken by various bodies are being advanced in silos without industrywide collaboration. Human factors is often seen as something separate from engineering work and even from safety activities. Human-factors education is separate from engineering and safety education. There is a clear need to integrate human-factors principles into the curricula of engineering and safety degrees and continuing-professional-development programs. The industry recognizes the importance of working with academia to develop innovative technology, and this practice should be extended to include human factors.

The industry recognizes that it must recruit diverse new talent, but human-factors graduates are rarely regarded as a target group during recruitment efforts; this contrasts with other industries such as EDF Energy which has an established Human Factors Graduate Scheme. This also must change to achieve the next level of safety performance.

What Might Be a First Practical Operational Step?

First and foremost, despite the 1,000-plus references returned when searching for “human factors” in OnePetro, there is little practical material in the way of processes that have a formal human-factors underpinning. This is especially true when it comes to incident investigation, well covered, in abstract, by IOGP publication 621.

As an example, the integration of human-factors concepts and tools in incident investigation requires a coordinated effort across multiple skill sets and work processes in order to

- Upskill investigators in human-factors techniques.

- Make it systematic through the integration with the competency management systems, selection, and promotion criteria.

- Integrate with quality-control mechanisms so that human error does not slip through as a root cause.

- Upskill stakeholders on what good practice looks like, e.g., senior and site leaders and legal teams, so they fully appreciate the significant influence of human factors on incidents.

- Extend existing policies and procedures to require the inclusion of human-factors analysis in all investigations.

- Modify report templates, checklists, and other aids used before, during, or after investigations to prompt appropriate and informed inquiry into the human-factors aspects of incidents.

- Update accident database and reporting forms to capture human factors findings and reporting trends in human-factors causes.

- Incorporate formal and informal mechanisms such as contractual language and performance-review meetings into contractor-management processes to ensure organizations working together learn effectively from incidents.

It is impossible to integrate human factors effectively into incident investigations by simply reading the available literature. The capability must be developed and systematically embedded into an ecosystem of processes, procedures, tools, and templates and through learning, coaching, and mentoring. As the aviation industry discovered, the journey requires much effort and progress takes several years.

Confronting the Challenges of Automation

Although written almost 40 years ago, Bainbridge (1983) provides a very clear and accessible summary of the ironies of automation and raises many issues that are still pertinent today. She highlights the fact that, even now, designers of automated systems tend to incorporate functions into systems that are straightforward to automate—but the difficult bits that they cannot automate they leave for the operator to sort out. In addition, Bainbridge notes that designer errors themselves can be a major source of problems. The difficulties associated with reverting to manual control are heavily dependent on the skill and experience levels of the operator.

Therefore, a second potential focus area for the SPE Human Factors Technical Section, in collaboration with the Drilling Systems Automation Technical Section, might be to address the question of the ergonomics and human-factors aspects of automation, especially in the case of drilling rig controls, alarms, and managed-pressure drilling systems. Human-factors-related risks are also present in the increasing levels of automation and digitalization seen in advanced well-planning software systems and smart rigsite systems intended to assist frontline operators, both of which underpin safety-critical design and operational decisions. The concern with such systems when conditions diverge from normal and the operator is required to resume control is whether the transition can be achieved safely or whether additional risks arise as a result of the startle factor compounded by skills degradation or lack of practice in manual control.

These factors were contributors to the loss of Air France flight AF447 in the South Atlantic in June 2009. The CSB (2019) highlighted at least two issues rooted in human performance that were a contributory factor in the tragic Pryor Trust blowout and fire. First, there was a lack of training and difficulties in using newly installed electronic trip-sheet software, with attempted workarounds for nonstandard fills. Second, the board observed that the ergonomics issue of the frequency of nuisance alarms was such that the drillers deactivated the system during the critical period when the incident was evolving.

What Is SPE’s Role in Advancing Human Factors?

SPE has created technical sections to advance technical knowledge and to promote and support interest in and uptake of specific techniques and technologies. For example, the Drilling Systems Automation Technical Section started in 2008 with little more than a mission to make some noise about drilling automation within the SPE community. The initiative progressed steadily with increasing activity in Forum Series meetings and Applied Technology Workshops. The section organized a regular half-day meeting prior to the annual SPE/IADC Drilling Conference, facilitated the inclusion of papers into conference sessions, and helped stimulate the foundation on which today’s digitalization agenda is based.

By analogy and despite the challenges faced in the post-COVID environment, the Human Factors Technical Section is well-placed to employ the established SPE infrastructure of events and publications to communicate an awareness across the spectrum of its membership. This section conveys the importance of human factors and the unique dependence on reliable human performance in the high-hazard activities undertaken by the exploration and production industry.

What Can SPE Members Do Today?

There are a number of things that we, as individual members, can do to develop our own insights into human factors and how human performance impacts our operations and organizations. In addition to joining the Human Factors Technical Section to gain a basic understanding of what human factors is about, members can take a 2–3 hour e-learning course developed by the Chartered Institute of Ergonomics and Human Factors in association with the Energy Institute.

Those interested in going further might wish to explore the HPOG website and become familiar with the Recommended Practice on Human Performance.

There are additional informative publications available from both the IOGP and the UK Energy Institute.

What Can SPE Members Do To Encourage Their Organizations?

Within their own organizations, SPE members can support HPOG by making the case for supporting and funding its activities, encouraging co-workers to pursue the Human Performance competency pathway, and by identifying human-factors champions and supporting them in introducing the human-factors initiatives described earlier and implementing the HPOG Recommended Practice. The major and most time-consuming challenge will lie in systematically promoting the development of competence in human factors throughout the organization across different groups and demographics; this will involve allowing people time to learn, providing incentives to do so, and recognizing their achievements.

For Further Reading

Bainbridge, L. 1983. Ironies of Automation. Automatica. Vol. 19, No 6, pp. 775–779, Pergamon Press Ltd.

US Chemical Safety Board. June 2019. Gas Well Blowout and Fire at Pryor Trust Well 1H-9. Investigation Report No. 2018-01-I-OK.

Skinner S. 2016. The Contribution of Human Factors in Getting Safety Right. IOSH Meeting, 4 July.

SPE 170575. 2014. Technical Report. The Human Factor: Process Safety and Culture.

SPE 173104. Getting to Grips with Human Factors in Drilling Operations by J.L. Thorogood, K. Lauche, M. Crichton, et al.

SPE 173010. Drilling Systems Automation Roadmap—The Means to Accelerate Adoption by J. de Wardt, J. Macpherson, Mario Zamora, et al.

IOGP. Reports 453, 460, 621, 476, 501, 502, 503. IOGP.

Energy Institute. Publications on Human Factors.

EDF Energy. Human Factors Graduate Scheme 2020.

Marcin Nazaruk is a human-performance and culture leader at Baker Hughes. As a psychologist, scientist, and safety practitioner, Nazaruk translates safety science into practical solutions to transform health, safety and the environment. He was elected chair of the SPE Human Factors Technical Section in August 2020. Connect on LinkedIn: https://www.linkedin.com/in/marcinnazaruk/

John Thorogood is a drilling engineering adviser at Drilling Global Consultant LLP, supporting multiple international operators and scientific research organizations in deepwater and high-pressure/high-temperature operations. He is the author of more than 60 articles and papers of which one-third relate to human factors, the challenges of drilling automation, and risk analysis. He was recognized by the 2020 SPE Technical Award in Health, Safety, and Environment. Connect on LinkedIn: https://www.linkedin.com/in/john-thorogood-9a44b819/. Email: jlt-spe@drillinggc.com.