DuPont is ramping up the commercial-scale implementation of its microbial enhanced oil recovery (MEOR) method after nearly a decade of development and testing of what it says is a low-risk way to improve production from mature fields. Using its bioanalysis technology, DuPont has isolated microbes able to promote flow conformance through the production of a biofilm that restricts flow by reducing permeability. The company has also identified and isolated microbes that have oil-releasing (or wettability-changing) qualities to reduce residual oil adhering to the rock. Based on successful results both in the lab and in the field, the company says that its MEOR solution can increase production rates by as much as 25% at a cost of USD 10 per incremental barrel. DuPont presented the details of its laboratory tests and discussed the results of field trials at the SPE Improved Oil Recovery Symposium in Tulsa in April.

Despite the extreme pressures, temperatures, and other harsh conditions found inside an oil reservoir, where there is water, there is often life. And while scientists and engineers have long known there to be thousands of species of bacteria found in these reservoirs, they have only recently begun to find how to make use of them, thanks to advancements in biotechnology and DNA analysis. “Most of these oil wells are very much alive with bacteria,” said John Fisher, a global technology manager at DuPont and a coauthor of several papers of the company’s MEOR technology. “The key is to identify the ones that will do the function that you want, isolate those, take them out of the reservoir, grow them up, and put them back in at a higher concentration.”

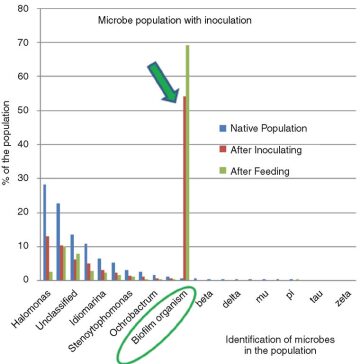

This process of reintroducing, or inoculating, a laboratory-grown batch of indigenous microbes into the reservoir is what DuPont says separates its MEOR technology from others. By starting off with a microbe that is already adapted for the reservoir’s unique environment, the chance that it will not survive is eliminated. But to get it to thrive, DuPont has developed a “tailored suite” of nutrients to be sent down into the reservoir to preferentially feed and grow the selected microbes. The initial inoculation operation can last 8 to 14 hours, but it requires production to be shut down for 5 to 6 days to allow the microbes and nutrients to flow deep into the reservoir—away from the near-wellbore area. After that, monthly injections of the nutrients, lasting about an hour each, are needed to sustain their greatly increased populations. Because the microbes are dependent on these regular deliveries of nutrients, DuPont’s MEOR process is completely reversible. “If you stop feeding them, they die and revert back to the natural levels they were at before, based on the food that was already there,” Fisher said.

With this MEOR technique, the operator also faces very low up-front cost. Because the process simply involves the deployment of bacteria and nutrients into the well, there is no significant capital investments. “You do not need to put in big expensive facilities like you do for a CO2 flood or polymer flood,” Fisher said. “You basically come in with a tank-truck of microbial solution and nutrients, pump it in the well, go away, and come back a month later to pump it in again.”

The criteria that DuPont has developed for the application of MEOR includes fields with reservoir temperatures below 160°F and moderate salinity levels of up to 100,000 ppm. The reservoir must also be undergoing a waterflood treatment and have permeability above 30 md to carry the microbes and nutrients deep into the reservoir, where they can establish a growth zone.