The Bakken Petroleum System, which includes the Bakken and Three Forks shales in North America, is estimated to hold as much as 900 billion bbl of original oil in place. However, the technically recoverable oil is a fraction of the total, estimated to be 20 billion bbl to 45 billion bbl, because most of the 8,000 producing wells have a recovery factor of about 3% to 10%.

“And in fact, 10% is anomalously high,” said James Sorenson, a senior researcher at the Energy & Environmental Research Center (EERC). “So it is clear with the enormous size of the prize in the ground that even small improvements in recovery could yield significant amounts of oil.”

Sorenson is leading a research project involving government agencies and several upstream companies in search of a way to squeeze more oil out of the Bakken for years to come by using CO2 for enhanced oil recovery (EOR). He presented the progress of the project at the recent Unconventional Resources Technology Conference.

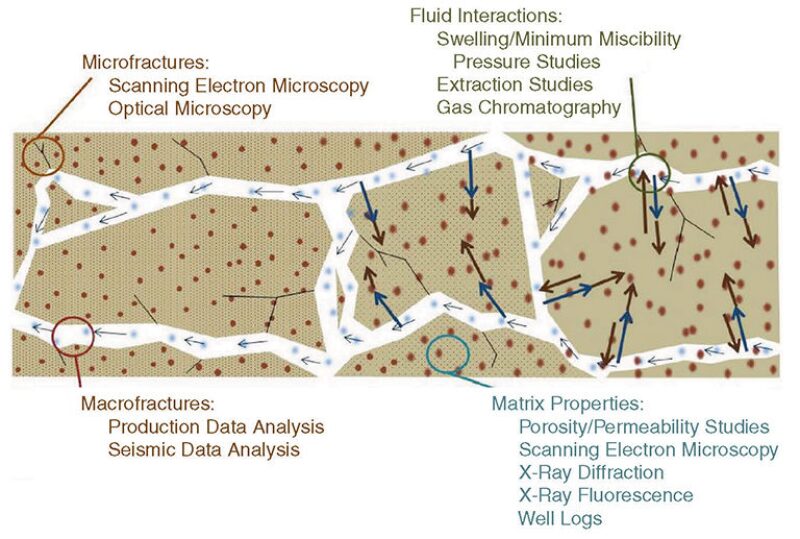

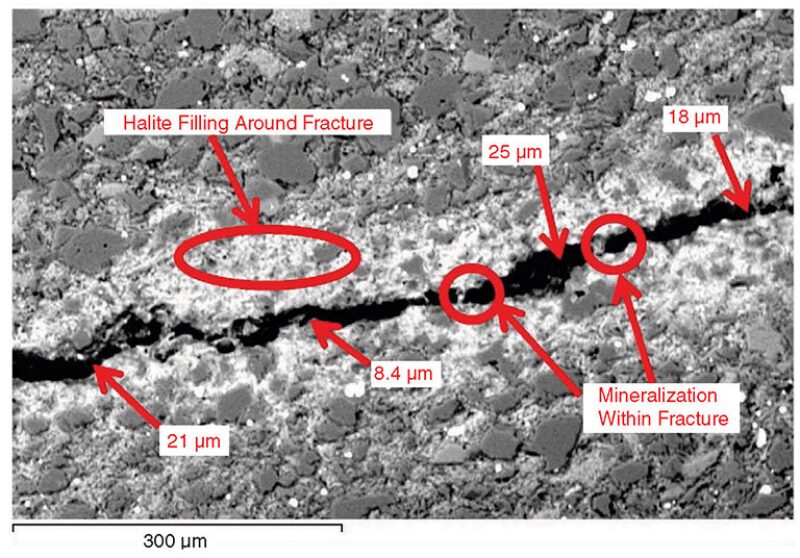

Sorenson said the key to understanding how well CO2 will work in tight formations is a deep understanding of how fluids move through tiny pores and microfractures. Microfractures account for much of the porosity and permeability in the Middle Bakken formation and will be important for EOR because they are also thought to contribute to long-term production.

So far, the research team has completed a series of studies using a wide range of technologies including scanning electron microscopes and computed tomography to identify rock characteristics that would allow trapped oil to be produced.

In experiments, the researchers have discovered that when small shale samples are placed into a high-pressure/high-temperature chamber and bathed with CO2, the oil will swell and its viscosity lowers enough so that it moves through the rock. “It demonstrates that oil can be extracted and that CO2 can also permeate the rocks,” Sorenson said.

This is different from CO2 flooding in conventional reservoirs in which the goal is to displace the oil and sweep it into the production zone. Some of the experiments were able to extract 80% to 100% of the oil from the shale samples in a 24-hour period. However, Sorenson said more experiments will be needed to get a better handle on the mechanisms involved in the process.

The information obtained from the laboratory testing has been run through computer models to see how the CO2 will affect production on a larger scale. Though the models showed that production could be improved, in some cases doubled, they also showed there is a clear delay in comparison with what happens during a CO2 flood in a conventional formation.

“Whereas in the conventional reservoir, you might see a response in a matter of days or weeks. Generally, in these Bakken models, we are seeing responses on the order of many weeks to months, to many months,” Sorenson said. “It underscores the notion that patience is going to be a virtue when it comes to doing any kind of serious EOR operation in these tight oil formations.”

One problem the project is working on involves customizing the models to better reflect the reality of the unconventional formations. Schlumberger, Computer Modelling Group, Baker Hughes, and Kinder Morgan are assisting the EERC with this aspect of the research.

Based on EOR tests carried out by other institutions, Sorenson said the improvements in oil production that were predicted by the models were not observed. “I would probably say not even close to having been observed,” he said. “There are clearly some significant gaps within the modeling and the reality in the field.”

Later this year, researchers will begin identifying field test locations, developing a test concept, and establishing baseline characterization and monitoring systems. The field tests are also likely to use unique injections schemes that Sorenson said would set the project apart from previous tests.