Though expensive and complex, extended-reach drilling (ERD) is moving more into the mainstream as the industry is driven to develop frontier reserves in fragile environments like the Arctic where drilling from shore to offshore targets reduces a project’s infrastructure costs and environmental footprint.

A form of directional drilling, ERD is also being used increasingly to tap into hard-to-produce reservoirs, making viable projects that might otherwise be written off as noncommercial.

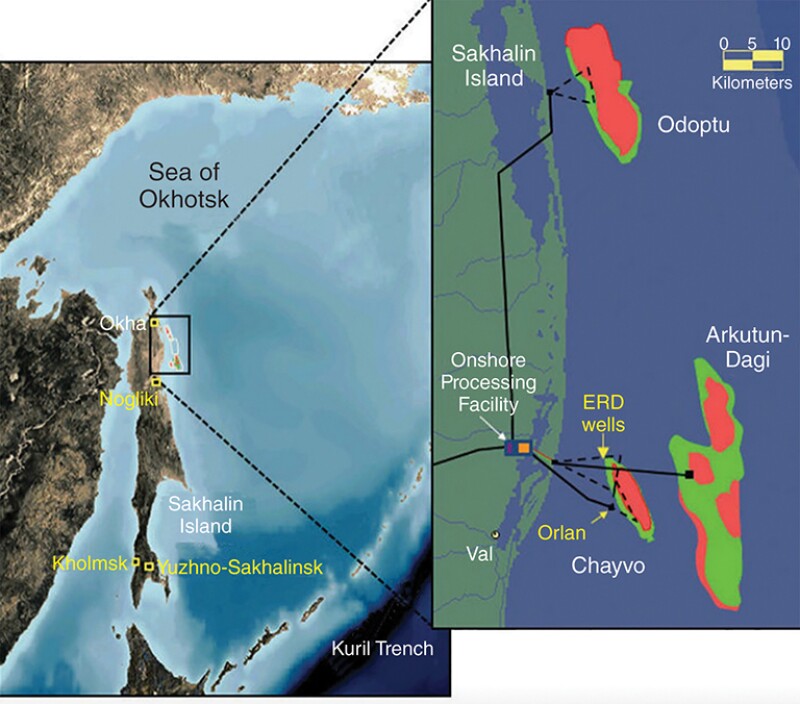

This article highlights how the Russian Far East became the ERD epicenter in the past decade, given ExxonMobil and Rosneft’s extensive use of ERD in developing Arctic resources offshore Sakhalin Island, and how ERD is becoming more widely used in regions as diverse as the Gulf of Thailand, offshore Brazil, and the Arab Gulf.

By definition, an extended-reach well (ERW) is one in which the ratio of the measured depth (MD) vs. the true vertical depth (TVD) is at least 2:1 (PetroWiki). An ERW differs from a horizontal well in that the ERW is a high-angle directional well drilled to intersect a target point, a feat requiring specialized planning to execute well construction.

ExxonMobil subsidiary Exxon Neftegas Limited (ENL), which operates the Sakhalin-1 license area offshore Russia’s Sakhalin Island (Fig. 1), has been pushing the limits of ERD for nearly 2 decades with innovative technologies and sophisticated well planning, making the Sea of Okhotsk a place where any ERD drilling record set today may easily be broken tomorrow.

Russia’s state-owned Rosneft (which has a 20% stake in Sakhalin-1) owns bragging rights for having drilled the longest ERW well on record to date. Rosneft announced in November 2017 it had drilled a 15000-m horizontal ERW from the offshore Orlan gravity-base platform at Chayvo field situated in 14 m water depth in the Sea of Okhotsk, topping four previous records set between 2013 and 2015 that had reached between 12450 m and 13500 m (Fig. 2).

In a news release at the time, Rosneft called the well “super complex with a DDI [directional drilling index] of 8.0 and a 14129-m stepout.” The release went on to say that the Sakhalin-1 Consortium could (as of the 2017 announcement) claim to have drilled nine out of the world’s 10 longest ERD wells.

According to Rosneft, the project had set five world records for measured depth of wells between 2013 and 2017. In April 2015, development well O-14 was drilled with a length of 13500 m. That broke a 2014 record when the 13000‑m Z-40 well was completed. In 2013, records were announced for wells Z-43 and Z-42 which were drilled, respectively, in April and in June 2013 with lengths of 12450 m and 12700 m.

Rosneft credited ExxonMobil’s patented “Fast Drill” drilling optimization process that can increase rates of penetration (ROP) by up to 400% as a significant innovation contributing to the ERD success story at Sakhalin-1.

One of the largest foreign direct investments in Russia, Sakhalin-1 operates under a production sharing agreement (PSA) with its license area off the northeastern coast of Sakhalin Island, comprising the Chayvo, Odoptu, and Arkutun Dagi fields.

ENL holds a 30% stake in Sakhalin-1 as project operator; its partners include two affiliates of Rosneft (RN-Astra, 8.5%, and Sakhalinmorneftegaz-Shelf, 11.5%); Japan’s SODECO Consortium, 20%; and India’s state-owned ONGC Videsh Limited, 30%.

SPE/IADC 119373, presented at the 2009 SPE/IADC Drilling Conference, offered a case study in the drilling of one of the early record breakers, the Chayvo Z-12 well, and detailed the well design and operational practices that enabled Sakhalin-1 to initially increase well reach to more than 10.5 km.

The first of the Sakhalin-1 fields to be developed, Chayvo, is described by the paper’s authors as “a gas-filled structural anticline with an oil rim.” Drillers first targeted the oil rim “using ERD techniques including horizontal completions up to approximately 3700 m in length from the Yastreb [drilling rig] land location [on Sakhalin Island] and from the Orlan offshore concrete island drilling and production platform [a gravity-base structure) offshore on Chayvo],” according to the authors.

Employing ERD to draw down Chayvo’s oil rim and generate cash flow from oil sales laid at the heart of the consortium’s business strategy from the beginning. Drilling ERWs from onshore to offshore targets helped sidestep at first some costs of having to work offshore in the Sea of Okhotsk with its punishing 1.5-m-thick ice sheets, high seas, and –40°C temperatures.

Now after nearly 20 years, ENL and its partners are preparing to switch into gas production. By late this decade, Rosneft and ExxonMobil expect to commission the first train of the Far East LNG plant to be constructed near the De-Kastri oil export terminal in the Khabarovsk region across the Tartar Strait from Sakhalin Island.

The Russian government greenlighted the project in the past year, though the partners have yet to make a final investment decision.

Parker Drilling engineered and built the Yastreb (Russian for “hawk”) exclusively for Sakhalin-1 to drill ERWs to offshore targets from land. Yastreb at the time was the world’s largest onshore drilling rig. Today, however, the Krechet on Sakhalin’s Odoptu field has taken over as the largest land rig that drills ERD wells to offshore targets, according to ENL’s website.

The consortium now is producing also from the Arkutun-Dagi field from a second gravity-base structure, the Berkut.

Applying ERD to Mature Fields in the Gulf of Thailand

Meanwhile in the tropics, Mubadala Petroleum (Thailand) Ltd. set its own “longest-ever” ERD completion in the Gulf of Thailand while researching the applicability of drilling ERWs to develop marginal oil reserves in the hard-to-produce reservoirs of the mature Jasmine offshore oilfield. Mubadala and Schlumberger coauthored IPTC 21488, presented at the 2021 International Petroleum Technology Conference, which noted that the “riskiest prospects in the Jasmine field are undeveloped, thin oil-rim accumulations, below thick gas caps,” not unlike the situation in Sakhalin.

Previous failed attempts to produce these gas-cap reservoirs by drilling deviated wells resulted in booking the reserves as “contingent resources” because of thin oil columns, the low volume of oil in place, and inefficiencies in recovery, the authors noted.

Mubadala, a wholly owned subsidiary of Mubadala Investment Company (owned by the government of Abu Dhabi), successfully drilled experimental ERD wells in Jasmine’s challenging thick gas cap and thin-oil-column reservoirs in 2017. This was followed by a second campaign from February to August 2019.

The authors noted in their paper that “the Jasmine field is a mature, sophisticated, oil field with many shallow reservoir targets that require a minimum 10,000-ft [3048-m] horizontal displacement.”

Mubadala drilled research Well X from the Jasmine-C platform (Fig. 3). The authors describe the well as “a three-string design structure with an 11¾-in. top hole, an 8½-in. intermediate section, and a 6⅛-in. reservoir horizontal section.” Well X was constructed by utilizing an existing platform well slot. The challenge involved drilling from the top hole to the kickoff point and drilling directionally away from the casing stump of the existing well to avoid any collision with nearby wells emanating from the Jasmine-C platform.

Despite the challenges posed by the complex well profile, lost circulation, and control of torque and drag, the well was completed successfully.

A total depth (TD) of 13,052-ft MD was achieved to reach reservoirs at 3,260-ft TVDSS. It was therefore announced in 2019 as a new ERD record for Mubadala Thailand (ERD ratio=3.26; directional difficulty index [DDI]=6.95), according to the authors. Full details describing how the well was drilled are available in the paper.

Offshore Brazil, Equinor Taps Tricky Reservoirs

OTC 28091, coauthored by Baker Hughes and Statoil (now Equinor) and presented at the 2017 Offshore Technology Conference Brazil, described the successful drilling of what was then Brazil’s longest horizontal section, 2268 m inside a depleted reservoir.

Though the Peregrino project in the post-salt zone of the Campos Basin poses major challenges for drilling, the authors credit their success to the use of a rotary-steerable system combined with a modular positive-displacement motor. The drilling scenario followed while geosteering was one of high torque, low weight on bit, and water-based drilling fluid, without any trips to change the drill bit, the authors wrote.

Equinor operates the Peregrino oil field which is located in licenses BM-C‑7 and BM-C-47, approximately 85 km offshore Brazil in the Campos Basin, in water depths of 100 m. The second phase is expected to be developed at a cost of $3 billion and will start production in 2022, according to Equinor’s website.

Phase 2 envisions the drilling of horizontal production wells with artificial lift that will be provided by subsurface, downhole electrical-submersible pumps (ESP), according to the paper’s authors.

Equinor a holds a 60% interest in what is its largest operated field outside of Norway. Sinochem is a minority partner in the concession which runs until 2040.

Island-Hopping Offshore Abu Dhabi in the Arab Gulf

Far from the icy Sea of Okhotsk, ExxonMobil is applying its ERD technologies in the world’s second-largest offshore oil field, the Upper Zakum field which lies offshore Abu Dhabi in the Arab Gulf.

ExxonMobil has a joint venture with field operator ADNOC Offshore; other shareholders include the Abu Dhabi National Oil Company (ADNOC) and Japan’s JODCO.

To reach a production target of 1 million B/D by 2024, the partners are implementing a development plan that includes the drilling of extended reach wells of up to 6 miles long, drilled from four artificial islands situated in the Gulf to achieve higher recovery while reducing costs and minimizing the operation’s effects on the environment, according to ExxonMobil.

SPE 202717, presented at the 2020 Abu Dhabi International Petroleum Exhibition and Conference, explains the technologies used to drill the UAE’s longest complex 3D ERD well on an artificial island using a slim casing design.

“This well was drilled with the objective to support the pressure sustainability of multiple producer wells across the Lukhweir-2 formation based on the ERD approach,” the authors wrote, adding that the ERD well had “a total measured depth of 27,352 ft (8.34 km) and having a horizontal hole of 11,300 ft (3.45 km reservoir contact) with directional difficulty index (DDI) of 7.208 using a light/slim casing design.”

Because of its effectiveness, the ERD well saved the operator the cost of drilling three separate wells that would have normally supported the producer well. This amounted to a savings of $18 million, according to the authors.

For Further Reading

SPE 119373 Increasing Sakhalin Extended-Reach Drilling and Completion Capability by Michael W. Walker, Andrew J. Veselka, and Shane A. Harris, ExxonMobil Development Company.

IPTC 21488 ERD Drilling Record Achieved in the Gulf of Thailand with an Outstanding Drilling Efficiency by Manchukarn Naknaka, Mubadala Petroleum(Thailand) Ltd.; Trinh Dinh Phu, Schlumberger; Khamawat Siritheerasas, Pattarapong Prasongtham, and Feras Abu-Jafar, Mubadala Petroleum (Thailand) Ltd.; and Ali Abbasgolipour and Pham Nam Hieu, Schlumberger.

OTC 28091 The Longest Horizontal Section Ever Drilled in an Extended-Reach Well in Brazil by Rafael Kenupp, Affonso Lourenço, Stian Soltvedt, Ian Thomson, Baker Hughes; and Grazielli Simões, Daniela L. Morosov, and Raquel Andrade, Statoil.

SPE 202717 Planning and Challenges of Longest Complex 3D ERD Well Drilled in United Arab Emirates Onshore Field Artificial Island Using Slim Casing Design by M. Asef Hashmi, Gamal Salem, Annie Morales, Basma Banihammad, and Sultan Mohamed Al Yamani, ADNOC Onshore.