Well-Sense has created a new fiber-optic well testing tool that goes into a well and never comes back.

The young company based in Aberdeen, Scotland, is working to alter the usual descriptions of fiber-optic intervention as a large, costly long-term investment. The equipment used for its FiberLine Intervention tool can be carried in the back of a pickup truck and run into a well with no heavy equipment required.

At the end of the job, company presentations show a technician on site cutting the fiber-optic cable at the wellhead. The fiber and the aluminum housing that delivered it in the well will go away in days or weeks. The time period allowed for the job, and the disappearance, will depend on the customer’s specifications, said Craig Feherty, the chief executive officer for Well-Sense.

The disappearing act is both a money saver—no expensive equipment needed to insert it or retrieve it, and if it gets stuck it will not last long —and a question raised by puzzled potential customers.

“The biggest one is leaving stuff in the well. That is the challenge, to change that mind set,” said Feherty. “Some customers adjust quickly and some are really cautious about it.”

The company recently made headlines after attracting investment from a prominent source. Well-Sense won the backing of Saudi Aramco Energy Ventures to support its growth. The investment, described as a “seven-figure” amount, will allow Well-Sense to add people and equipment to expand, particularly in the Middle East.

Skepticism is a given for a young company selling an emerging technology based on an invention employing unconventional thinking by its inventor Dan Purkis, the company’s founder and technical director.

Well-Sense has done commercial jobs with FiberLine. Feherty said it has used it to detect leaks and monitor the quality of a cement job based on the heat of the cement as it cures. Its list of possible uses includes microseismic monitoring, fracturing diagnostics, and gas lift inspections.

Its capabilities can be increased by adding sensors to the cylinder at the end. One client installed a small off-the-shelf camera and used the fiber-optic to stream video to the surface.

The gravity-based delivery system works in vertical wells when not producing. The company is working on alternate delivery methods for holes tilting horizontal (a maximum deviation of about 60 degrees). It will be testing whether it can reliably pump it into the well and are also working on building a conveyance tool to pull it down a horizontal well.

Traveling Light

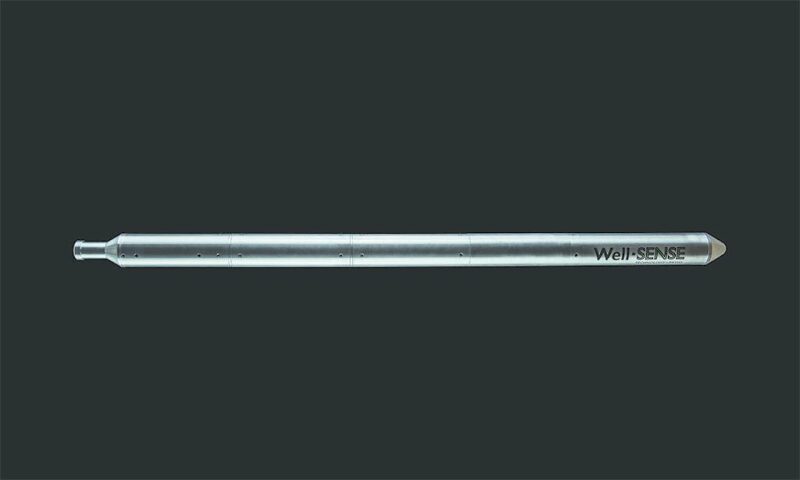

Compared with standard logging tools it is a light load. The fiber, which is thinner than a human hair, is spooled out of an aluminium cylinder about 2 in. in diameter and 40 in. long that contains 15,000 ft of fiber-optic line. That, plus the hardware used to safely insert it into a well, weighs less than 33 pounds, Feherty said.

Well-Sense is selling a system to collect distributed acoustic sensing and temperature data sensing and deliver it to a laptop using an adapter plug it developed. Processing the data is up to the user. Well-Sense’s goal is to sell a data collection service that is compatible with all of the software used to interpret fiber-optic data.

There are competitors selling other ways to insert fiber optics. Feherty says their option costs considerably less to use because it does not require wireline or coiled tubing equipment.

The work of recording the sounds, temperatures, pressure, and flow at every meter along the wellbore depends on a strand of bare fiber 200 microns thick. While the fiber looks like it is filling the role of a wireline suspending the tool in the hole, the design minimizes weight on the fiber by unspooling it as the fiber line tool sinks. Feherty likens it to holding the end of a ball of string and letting it drop to the floor.

Exposing fiber-optic line with minimal protection in water is normally avoided because water can ruin fiber. “This is the beauty of thinking outside the box. Normally, fiber’s nemesis is water” so it is packaged inside waterproofing tubing with added layers of protection.

Well-Sense uses basic fiber-optic line, with coating offering short-term protection. Job times can range from hours to days depending on the fiber and metal used. The casing life can be shortened, at a cost, by making it from alloys that can decompose in hours.

Feherty said customers so far have chosen aluminium. The aluminium used is not coated to resist damage when exposed to acidic or alkaline water in a well, and typically degrades in about a month.