Thanks to the advent of high-speed drilling in the US shale sector, the effects of so-called frac hits on production and well economics is becoming more important than ever. It means the clock is running for shale producers to figure out how to mitigate the implications of this well-to-well interference issue before they drill too many wells too close together.

Multiple perspectives on the topic were presented at this year’s Unconventional Resources Technology Conference in Austin, Texas. Included among them was a technical paper authored by engineers at Shell that used a simple capital expenditure formula to illustrate the financial risks involved with getting the spacing question wrong.

According to the paper’s authors, if a shale producer has an inventory of 2,000 640-acre drilling sections, and each new well costs $5 million, then adding just a single unneeded well to each section would cost the operator $10 billion.

In a separate paper also delivered at the conference, Schlumberger highlighted the other downside to suboptimal spacing: poorer than expected production. The company analyzed IHS data from 300 horizontal wells in the Avalon Shale of the Delaware Basin and found that child wells (the youngest wells on a pad site) were almost 30% less productive compared with parent wells.

“[Operators] see that the child well does not produce as much as the parent wells—or they see that when the child well is drilled, there is a negative impact on the parent well,” explained Foluke Ajisafe, a production and stimulation engineer at Schlumberger who led the study.

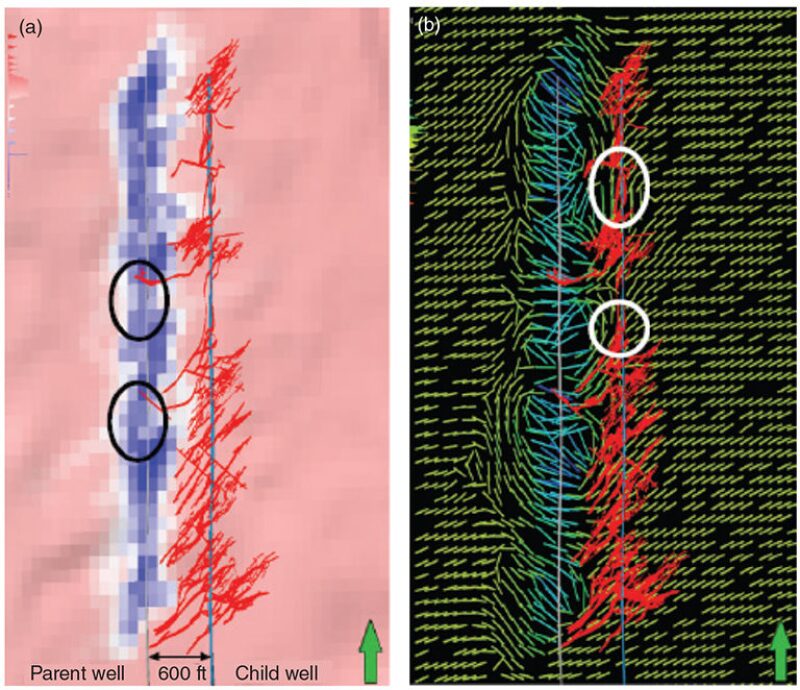

The driving factors she cited were how production over time creates stress rotation and leads to pressure depletion zones, known as pressure sinks. The paper describes two types of frac hits: one is a child well fracture that grows within a pressure sink and moves toward the parent well. The other involves a “stress vortex” that “can channel a fracture” as stress orientations change and align.

Spacing Indicator

Though it is difficult to frame this production-impacting problem as a good thing, it is likely to become one of the shale sector’s most important learning tools going forward. Richard Cao, a staff reservoir engineer at Shell who led the aforementioned study, is among those taking that track.

“People keep asking, is the pressure interference a good thing or a bad thing,” he said, using one of the industry’s euphemisms for frac hits. He explained that while they are undesirable from a safety point of view due to surface and well control risks, “in terms of well spacing, fracture hits could be a very good thing.”

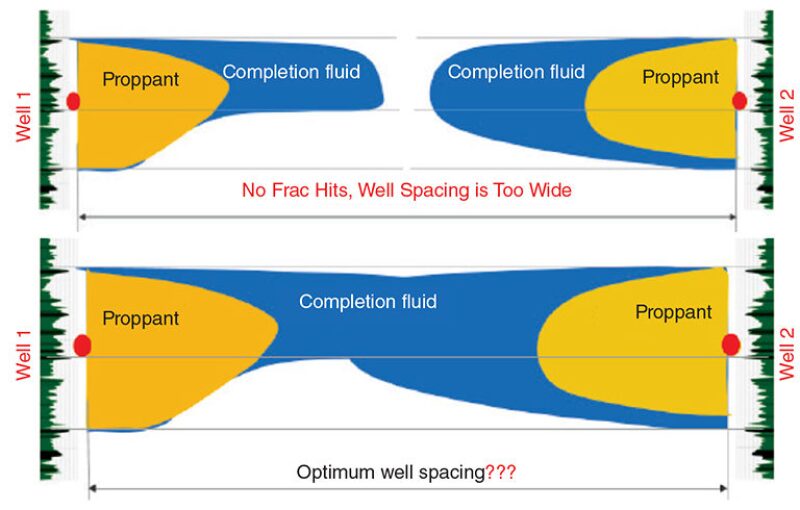

He makes the point that if horizontal wells on a pad site show no signs of frac hits, then it is likely they are spaced too far apart, lowering the overall economic recovery of that section. As wells are drilled closer and hydraulically fractured, Cao notes that the odds of frac hits rises, at which point they become a “direct indictor” of just how many wells can economically fit in a drilling section.

Bubblepoint Matters

Chevron has come up with another way to think about frac hits, which involves scrutinizing the bubblepoint of parent oil wells. Also presented at the unconventionals conference, this study argued that if a well is producing above the bubblepoint then a frac hit is not as likely to delay its production, which may mean there are minimal impediments to that well’s ultimate recovery.

However, if frac hits take place around the parent well when it is producing below the bubblepoint then they may induce gas trapping in the reservoir matrix. The research makes clear that this would have “long-lasting effects” on ultimate recoveries.

“The trapped gas, isolated from the continuous fluid path in the matrix near the fractures, can hinder the oil productivity,” the paper said. The advisement given is that operators should avoid initial completions and refracturing if they know a well is flowing below the bubblepoint. This would suggest that the closer in time that multiple completions and refracturing operations take place, the lower the risk is of pad wells suffering from irreparable frac hits.

Agreement Among Studies

Statoil’s research on frac hit mitigation was also presented at the conference and shares some agreement with what Shell and Schlumberger have learned. Using a case study from the Eagle Ford Shale, the Norwegian operator found that because of fracture overlapping and “aggressive production interference,” the decline rates of wells drilled just 250 ft apart “were much stronger than wells spaced further apart.”

The research concluded that 400-ft well spacing should be used instead to maximize the study area’s resource potential—effectively serving as a call to retreat from overly aggressive downspacing.

The finding was backed by extensive modeling and data analytics work that involved the production histories of almost 400 wells. Simulations also showed that using a staggered well layout, also known as a chevron configuration, could help mitigate long-term fracture interference.

Additionally, Statoil looked at how lower completion fluid injection rates could help control lateral fracture growth, which the model suggests is a feasible idea. Comparing an injection rate of 75 bbl/min to 35 bbl/min, a simulation found that the latter rate helped minimize frac hits and reduced overlapping of conductive fractures during production.

Testing Frac Hit Mitigation

The Schlumberger study in the Avalon Shale also relied on modeling work to test new frac hit mitigation strategies that included volume reductions for hydraulic fracturing treatments.

The modeling showed that dialing back the treatments lowers the risk of causing frac hits. Smaller job sizes would also carry a smaller capital cost for the operator, which may help balance a child well’s economics.

Schlumberger scrutinized well staggering too and used three scenarios to illustrate how it may be one of the best pathways to frac hit mitigation: a child well with 1,320-ft lateral spacing, 660-ft lateral spacing, and 660-ft lateral spacing with a 150-ft lower landing zone. The results were stark.

Simulated child wells with 1,320-ft spacing saw only 5% less cumulative oil production vs. the parent well over 5 years while 660-ft-spaced wells saw 24% less production over the same span.

The modeling work also showed that the more distantly positioned child wells created “little or no production interference” while the 660-ft spacing layout saw fracture hits originating from the child wells and into the parent wells.

Representing what may be considered a compromise in the elusive quest for “optimal” well spacing, the models indicated that child wells drilled 660 ft apart and 150 ft deeper will see only a 10% drop in production over 5 years compared with their parents.

“When you are able to land deeper, you actually improve the economics of that well,” summed up Ajisafe, who noted that this study is “by no means” a field-wide prescription due to the inherent heterogeneity of shale geology.

She emphasized that to obtain such learnings operators must take on this homework for each area of concern. “What would be ideal is to understand the reservoir characteristics and to do some good due diligence to understand the trends in petrophysics, geomechanics, and discreet fracture networks—those are very important,” she said.

For Further Reading

URTeC 2690466 Impact of Well Spacing and Interference on Production Performance in Unconventional Reservoirs, Permian Basin by Foluke Ajisafe, Schlumberger et al.

URTeC 2662893 Understanding the ‘Frac-Hits’ Impact on a Midland Basin Tight-Oil Well Production by Hao Sun, Chevron et al.

URTeC 2695433 Well Spacing Optimization in Eagle Ford Shale: An Operator’s Experience by Mehdi Rafiee and Tarun Grover, Statoil.

URTeC 2691962 Well Interference and Optimum Well Spacing for Wolfcamp Development at Permian Basin by Richard Cao, Shell Exploration & Production et al.