Hydrate blockages can wreak financial havoc on operators. Companies looking to avoid the deferred production and remediation costs incurred by hydrate issues often design and operate fields with a philosophy of avoiding hydrate formation. However, a flow assurance engineer at BP said that this philosophy may not be sufficient as operators move to more extreme environments, and that a shift in focus from complete avoidance to an overall risk management strategy may be warranted.

At a technical session held during the 2017 Offshore Technology Conference, Anjushri Kurup spoke about the evolution of BP’s hydrate management philosophy for a dry tree facility in the US Gulf of Mexico.

The unnamed facility Kurup discussed operates in 4,500-ft water depth. The asset has several producing wells with water cuts ranging from 15 to 70%. He said that the asset was originally designed to avoid any hydrate formation, but that philosophy changed as water cuts increased and wells were put on gas lift. As a result, BP shifted away from a hydrate avoidance strategy to one focused on the efficient management of hydrate blockage risk, with the understanding that hydrate formation is not a guarantee of future hydrate blockage.

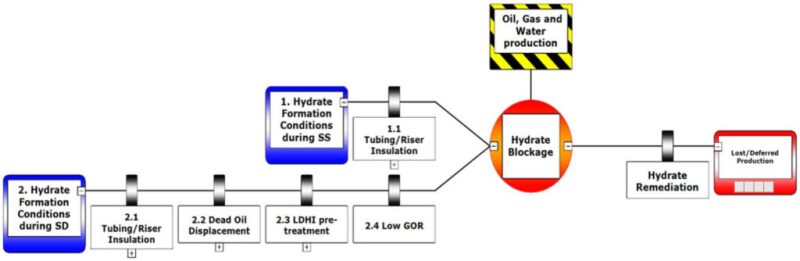

Fig. 1 illustrates the hydrate management philosophy. The hazard was the simultaneous production of oil, gas, and water that could lead to hydrate formation and a blockage in the production tubing.

The left side of the figure shows the preventative barriers put in place to avoid hydrate formation:

- Tubing/riser insulation. During steady-state production, the fluids are warm enough to be outside the hydrate-forming range and, hence, the tubing insulation acts as the preventative barrier. In the case of a shutdown the tubing insulation keeps the fluids warm temporarily, but cold ambient temperatures may cause the fluids to cool down, creating conditions for hydrate formation.

- Dead oil displacement. Kurup said that use of dead oil to displace production fluids down the dry tree tubing into the reservoir is the most relied-upon barrier for hydrate management. For unplanned shutdowns, it is the only available barrier.

- LDHI pre-treatment. In a planned shutdown, Kurup said fluids can be pretreated with an injection of a low-dosage hydrate inhibitor [LDHI], but that this is not a preferred solution to shutdowns of long duration.

- Low gas/oil ratio. At the dry tree facility, fluids with low gas/oil ratios were not reported to have any hydrate blockages.

Should all the preventive barriers fail, other mitigating barriers such as depressurization and hot oil circulation using thermodynamic inhibitors, such as methanol, monoethylene glycol, or nitrogen, could be used.

Following a shutdown, fluids cool down to the cold ambient conditions. In order to prevent hydrate blockage in the tubing, BP’s philosophy was to perform hydrate safe-out measures—measures implemented to prevent hydrate formation—within the cooldown time. However, even the cooldown times for each well in the asset ranged from 1 to 4 hours depending on whether the wells produced with gas lift. Kurup said these cooldown times were problematic.

“With such low cooldown times, it becomes very difficult operationally to employ any kind of hydrate safe-out measures in such a short period of time, especially when you have multiple wells that you have to look out for,” she said.

BP altered its hydrate management strategy to account for this and other issues. The no-touch time was increased, particularly for wells that were not being gas lifted. Kurup said this offered several advantages, including reduced wear and tear of the dead oil pumps and decreased topsides burden of processing dead oil from the tubing. The overall strategy centered around a reliance on the correlation between predicted hydrate volume fraction at the operating gas/oil ratio, the production water cut, and the risk of hydrate blockage.

For Further Reading

OTC 27780 Pushing Conventional Boundaries of Hydrate Management in a Dry Tree Facility by A.S. Kurup, T. Idstein, C.A. Zamora et al., BP